Subject to change without prior notice

4

\\W2s\users\minnara\käyttöhjeet\Kolmeks_FCkäyttöohje\Manual_FCpumps_en_20080506.indd

The pump and motor constitute a unit, where the rotating parts of both the pump and the motor are on the same

shaft (mono-block design). The motor is of a dry type and the frequency converter is integrated to the electric motor.

Electric motor: Totally enclosed, fan cooled A.C. motor, with frequency converter.

Protection form: IP54

Insulating class: F

3.1 Construction

3. Design and function

3.2 Technical data

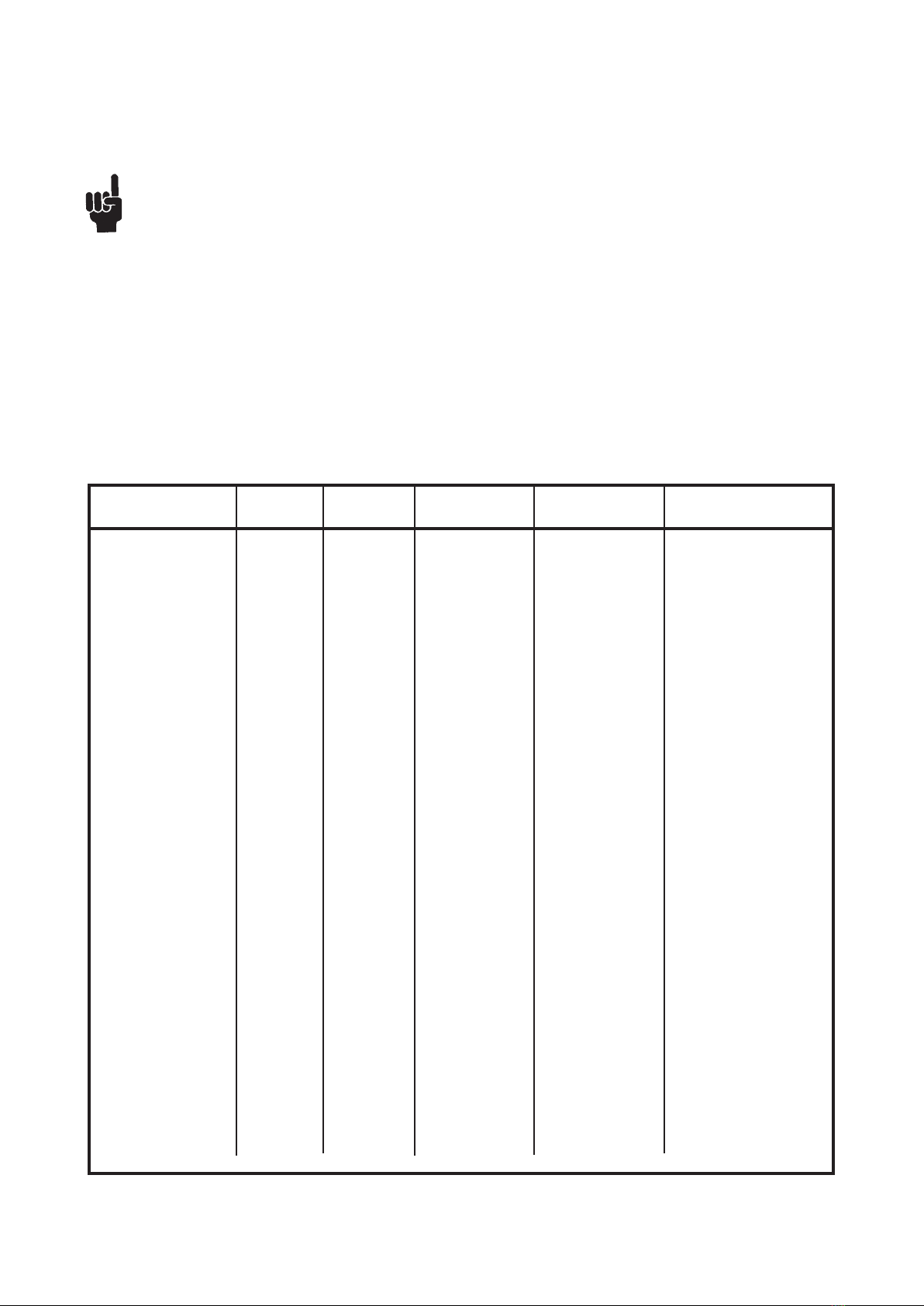

Pump type Flanges Weight kg(* Max. input Nominal current Twin pump

power kW A (400 V)

AE_-25/4,-26/4FC_ G 1 15 0,27 0,53 -

AE_-25/2,-26/2FC_ G 1 20 0,85 1,5 -

AE-32/4, -33/4FC_ G 1 1/4 20 0,5 0,9 -

AE-32/2, -33/2FC_ G 1 1/4 20 1,5 2,6 -

L_-32A/4FC_ DN32 19 0,27 0,53 T-32A/4FC_

L_-32A/2FC_ DN32 25 0,85 1,5 T-32A/2FC_

L_-40A/4FC_ DN40 25 0,5 0,9 T-40A/4FC_

L_-40A/2FC_ DN40 29 1,5 2,6 T-40A/2FC_

L_-50A/4FC_ DN50 33 0,7 1,4 T-50A/4FC_

L_-50C/2FC_ DN50 49 2,5 4,5 T-50C/2FC_

L_-65A/4FC_ DN65 47 0,7 1,4 T-65A/4FC_

L_-65A/4FC_ DN65 56 1,6 2,6 T-65A/4FC_

L_-65A/4FC_ DN65 67 2,8 4,7 T-65A/4FC_

L_-65B/2FC_ DN65 69 4,3 6,9 T-65B/2FC_

L_-65B/2FC_ DN65 100 8,0 12,4 T-65B/2FC_

L_-80A/4FC_ DN80 48 0,7 1,4 T-80A/4FC_

L_-80A/4FC_ DN80 62 1,6 2,6 T-80A/4FC_

L_-80A/4FC_ DN80 76 3 4,9 T-80A/4FC_

L_-80A/2FC_ DN80 74 4,3 6,9 T-80A/2FC_

L_-80A/2FC_ DN80 105 8,0 12,4 T-80A/2FC_

AL_-1032/4FC_ DN32 25 0,5 0,9 T-40A/4FC_ (DN40)

AL_-1032/2FC_ DN32 29 1,5 2,6 T-40A/2FC_ (DN40)

AL_-1066/4FC_ DN65 47 0,7 1,4 T-65A/4FC_

AL_-1066/4FC_ DN65 56 1,6 2,6 T-65A/4FC_

AL_-1066/4FC_ DN65 67 2,8 4,7 T-65A/4FC_

AL_-1065/2FC_ DN65 69 4,3 6,9 T-65B/2FC_

AL_-1065/2FC_ DN65 100 8,0 12,4 T-65B/2FC_

AL_-1081/4FC_ DN80 62 1,6 2,6 T-80A/4FC_

AL_-1081/4FC_ DN80 76 3 4,9 T-80A/4FC_

AL_-1081/2FC_ DN80 74 4,3 6,9 T-80A/2FC_

AL_-1081/2FC_ DN80 105 8,0 12,4 T-80A/2FC_

AL_-1102/4FC_ DN100 70 1,6 2,6 AT-1102/4FC_

AL_-1102/4FC_ DN100 86 3,7 5,8 AT-1102/4FC_

AL_-1106/4FC_ DN100 170 4,4 7,2 AT-1129/4FC_

AL_-1106/4FC_ DN100 200 8,3 13,0 AT-1129/4FC_

AL_-1129/4FC_ DN125 175 4,4 7,2 AT-1129/4FC_

AL_-1129/4FC_ DN125 205 8,3 13,0 AT-1129/4FC_

Noise level of all pump types is under 70 dB (A, 1 m).

(* Single pump weight (AL). The weight of the twin pump (T/AT) is depending on the size of the motor and equipment

each unit. The weight of the twin pump is about two times the single pump weight.

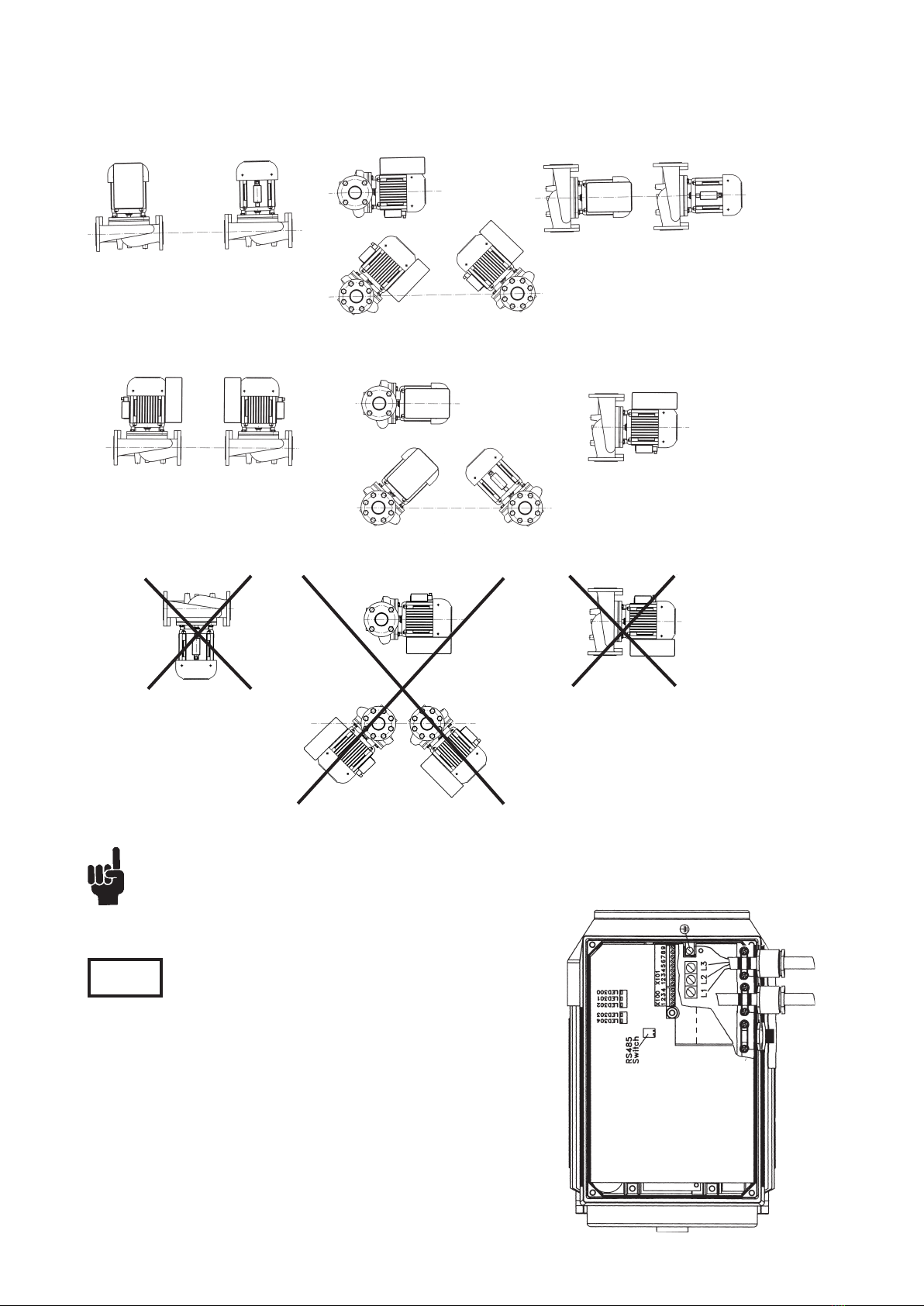

Normally the pumps are stable when they are transported and don’t go down even they are bent 10°. Pumps

shall be stored in a dry and cool place protected from dust. Temperature of environment must be in -10 °C ...

+50°C. It is not allowed to lift the pump from frequency converter. In the case of longer storage time or the

pump serves as a stand-by, it is recommended to rotate the pump manually f.ex. from the motor fan at least

once a month.

2. Handling, transport and storage of the pump

2.1 Handling, transport and storage of the pump