UAB KOMFOVENT we reserve the right to make changes without prior notice 3

V2-C5.1-17-07

Content

1. VERSO AIR HANDLING UNITS .................................................................................................................... 5

1.1. VERSO Air Handling Units marking.......................................................................................................... 6

1.2. VERSO-S – Air Supply Units .................................................................................................................... 7

1.3. VERSO-P/PCF – Air Handling Units Equipped with Plate Heat Exchanger ............................................. 7

1.4. VERSO-R/RHP – Air Handling Units Equipped with Rotary Heat Exchanger .......................................... 8

1.5. Brief Description of the Unit...................................................................................................................... 8

1.6. VERSO Air Handling Units Composing Options....................................................................................... 9

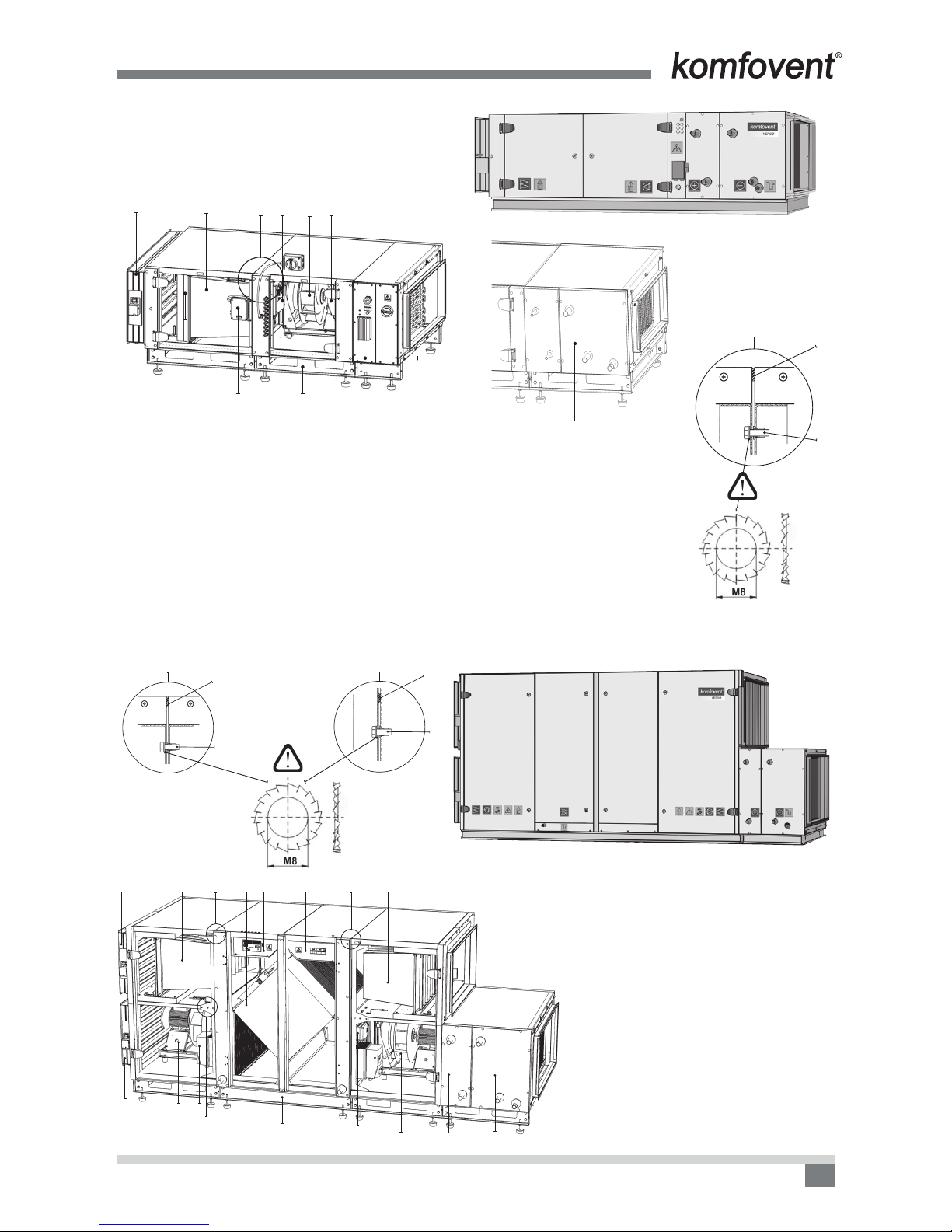

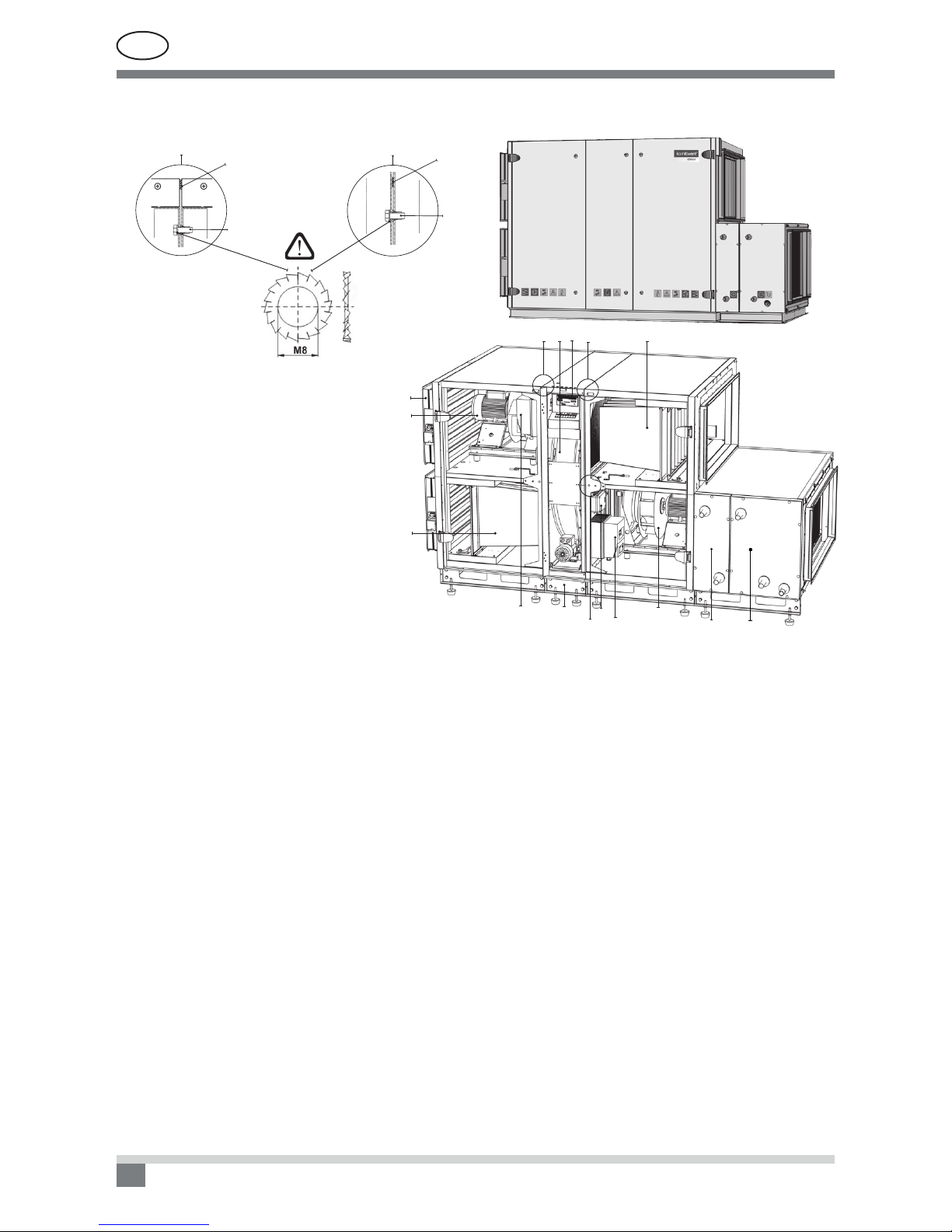

2. VERSO AIR HANDLING UNITS CONSTRUCTION................................................................................... 10

2.1. Fans........................................................................................................................................................ 10

2.2. Plate Heat Exchanger in VERSO-P/PCF Air Handling Units.................................................................. 10

2.3. Rotary Heat Exchanger in VERSO-R/RHP Air Handling Units ............................................................... 12

2.4. Verso RHP units ..................................................................................................................................... 13

2.5. Air Dampers............................................................................................................................................ 16

2.6. Air Filters and Filter Change Procedure.................................................................................................. 16

2.7. Water Air Heaters, Air Coolers, Direct Evaporation Air Coolers.............................................................. 17

2.8. Electric Air Heaters in VERSO-S Series Air Handling Units ................................................................... 21

2.9. Electric Air Heaters in VERSO-P/PCF and VERSO-R/RHP Series Air Handling Units .......................... 21

2.10. VERSO Series Air Handling Units Designed for the Outdoor Use ....................................................... 23

3. VERSO AIR HANDLING UNITS TRANSPORTATION............................................................................... 24

4. VERSO AIR HANDLING UNITS INSTALLATION ...................................................................................... 25

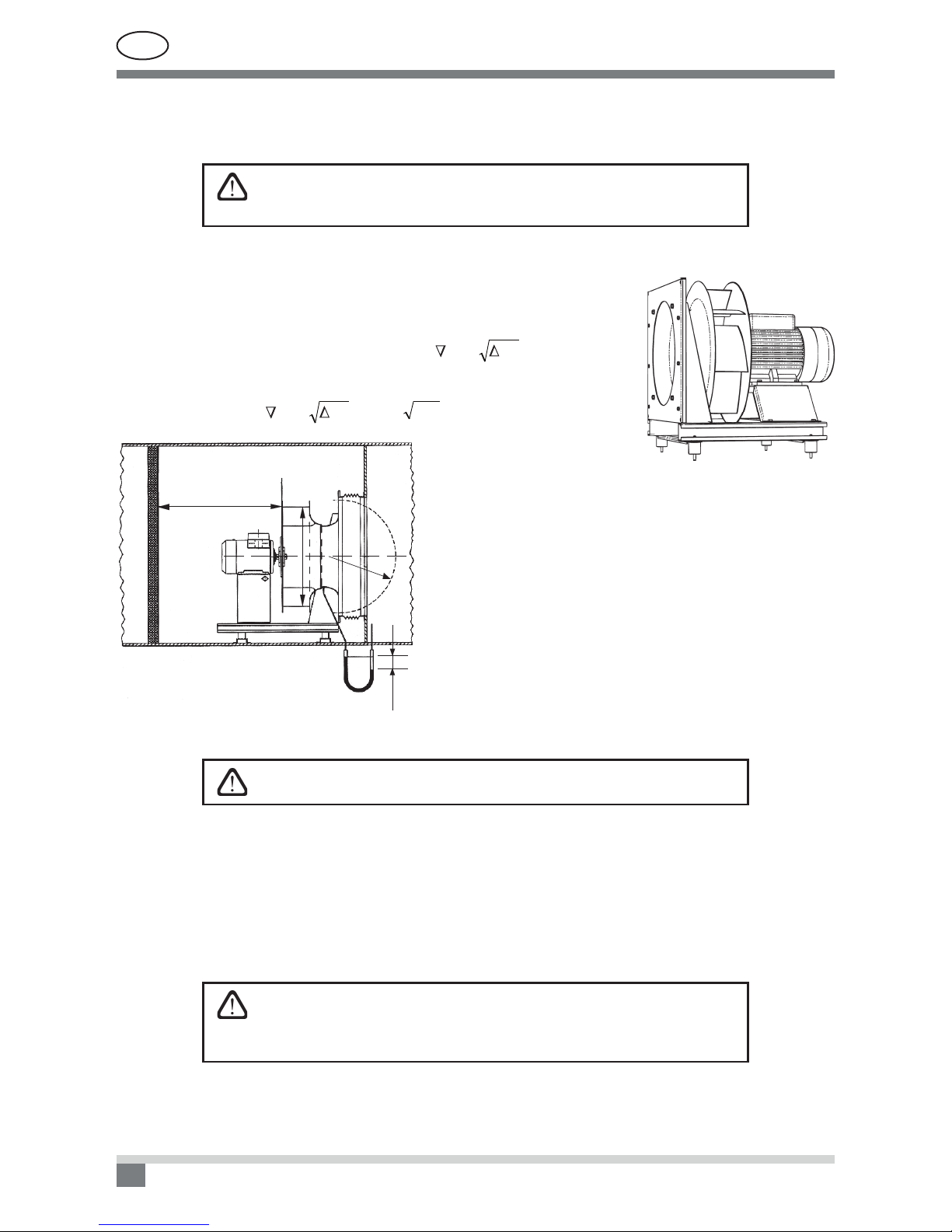

4.1. VERSO Air Handling Units Maintenance Space..................................................................................... 25

4.2. Setting and Installing VERSO Air Handling Units ................................................................................... 26

4.3. Connection to the air duct....................................................................................................................... 27

4.4. VERSO Air Handling Units Sloping Drain Tray....................................................................................... 27

4.5. Check-up before turning on VERSO Air Handling Unit........................................................................... 28

5. ELECTRICAL INSTALLATION MANUAL................................................................................................... 29

5.1. Air Handling Units Sections Connection ................................................................................................. 29

5.2. Electric Power Supply Connection.......................................................................................................... 29

5.3. External Elements Connection ............................................................................................................... 29

5.4. Temperature Sensors Installation ........................................................................................................... 31

5.5. Requirements for the installation of the control panel ............................................................................ 31

5.6. Control panel connection........................................................................................................................ 31

6. OPERATION MANUAL................................................................................................................................. 32

6.1. Unit Control............................................................................................................................................. 32

6.2. Control panel indication .......................................................................................................................... 32

6.3. Parameters overview.............................................................................................................................. 33

6.4. Operation modes selection..................................................................................................................... 33

6.5. Menu....................................................................................................................................................... 33

6.5.1. Overview ...................................................................................................................................... 34

6.5.1.1. Alarms ............................................................................................................................. 34

6.5.1.2. Operation counters.......................................................................................................... 34

6.5.1.3. Efciency status .............................................................................................................. 34

6.5.1.4. Detailed information ........................................................................................................ 34