Komfovent DOMEKT series User manual

DOMEKT

User Manual

EN

2UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

EN

CONTENT

1. INTRODUCTION..........................................................................................................................................................................................................3

2. AIR HANDLING UNIT FUNCTIONS ....................................................................................................................................................................4

2.1. Air ow control......................................................................................................................................................................................................4

2.2. Temperature control............................................................................................................................................................................................4

2.3. Standard operating modes...............................................................................................................................................................................5

2.4. Special operating modes...................................................................................................................................................................................5

2.5. ECO mode ...............................................................................................................................................................................................................5

2.6. AUTO mode ............................................................................................................................................................................................................6

2.6.1. Weekly operation schedule...................................................................................................................................................................6

2.6.2. Air quality control function...................................................................................................................................................................6

3. CONTROL AND SETTINGS.....................................................................................................................................................................................8

3.1. Control panel C6.1................................................................................................................................................................................................8

3.1.1. Parameter overview..............................................................................................................................................................................10

3.1.2. Turning on ................................................................................................................................................................................................10

3.1.3. Turning o ................................................................................................................................................................................................11

3.1.4. Mode change .......................................................................................................................................................................................... 11

3.1.5. Air quantity and temperature settings ..........................................................................................................................................12

3.1.6. Air quality control mode activation and settings ......................................................................................................................13

3.1.7. ECO mode activation and settings..................................................................................................................................................14

3.1.8. Creating a weekly operation schedule ..........................................................................................................................................14

3.1.9. Main settings...........................................................................................................................................................................................16

3.1.10. Advanced settings ..............................................................................................................................................................................17

3.1.11. Alarms......................................................................................................................................................................................................21

3.2. Control panel C6.2.............................................................................................................................................................................................22

3.2.1. Turning on/o and changing operation modes.........................................................................................................................22

3.2.2. Messages...................................................................................................................................................................................................22

3.2.3. Control panel sounds...........................................................................................................................................................................22

3.2.4. Keypad lock.............................................................................................................................................................................................. 23

3.3. Control via smartphone.................................................................................................................................................................................. 23

3.3.1. Connection to the air handling unit with a“Komfovent Home”app.................................................................................. 23

3.3.2. Connection to the air handling unit with a“Komfovent Cloud”app ..................................................................................24

3.4. Control via computer.......................................................................................................................................................................................24

3.4.1. Turning on/o and changing operation modes.........................................................................................................................26

3.4.2. Parameter overview..............................................................................................................................................................................27

3.4.3. Air quantity and temperature settings ..........................................................................................................................................28

3.4.4. ECO and AUTO mode settings ..........................................................................................................................................................29

3.4.5. Ventilation by a weekly schedule.....................................................................................................................................................29

3.4.6. Creating a weekly schedule ...............................................................................................................................................................30

3.4.7. Alarms........................................................................................................................................................................................................31

3.4.8. Settings......................................................................................................................................................................................................32

4. TROUBLESHOOTING.............................................................................................................................................................................................35

4.1. Table of messages .............................................................................................................................................................................................35

4.2. Table of light indicators of the C6.2 control panel.................................................................................................................................37

5. PERIODICAL MAINTENANCE............................................................................................................................................................................ 38

5.1. Filter inspection and replacement.............................................................................................................................................................. 38

5.2. Device maintenance journal .........................................................................................................................................................................45

3

UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

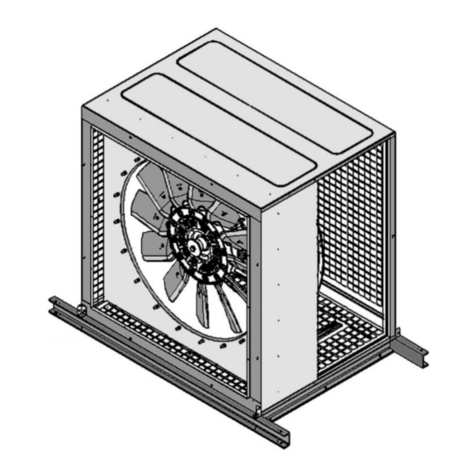

1. INTRODUCTION

The air handling unit is designed to ensure good ventilation of premises. Air handling unit removes indoor air containing

carbon dioxide, various allergens or dust, while replacing it with ltered fresh air from outside. As the outside air is usually

colder or warmer than the air within the premises, an integrated recuperator collects thermal energy from the indoor air and

transfers the majority of it to the supply air.

When a recuperator is not capable of reaching a desired temperature, heaters or coolers may be additionally activated.1

Heat exchangers and heaters (or coolers) are designed to compensate for heat/cool losses during

ventilation, therefore, we do not recommend using the unit as the main heating/cooling source. The

unit may not reach a user-dened supply air temperature when the actual room temperature dif-

fers signicantly from the desired room temperature. This will lead to inecient operation of a heat

exchanger.

Make sure that the unit is installed in a designated location, all ducts and wires are connected before

turning it on. Check for foreign objects, debris or tools inside the unit. Make sure that air lters are

installed and condensate drainage is connected (if necessary). If in doubt, contact your installer or

“Komfovent” representative to make sure that the unit is operational.

We recommend that you always keep your device turned on; when no ventilation is required, you

shall operate the unit in a minimum mode (20%). This will ensure good indoor climatic conditions

and will reduce humidity condensation inside the unit, that may damage electronic components.

This symbol indicates that this product is not to be disposed of with your household waste, according to

the WEEE Directive (2002/96/EC) and your national law. This product should be handed over to a designated

collection point, or to an authorised collection site for recycling waste electrical and electronic equipment

(EEE). Improper handling of this type of waste could have a possible negative impact on the environment and

human health due to potentially hazardous substances that are generally associated with EEE. At the same

time, your cooperation in the correct disposal of this product will contribute to the eective usage of natural

resources. For more information about where you can drop o your waste equipment for recycling, please con-

tact your local city oce, waste authority, approved WEEE scheme or your household waste disposal service.

1 Depends on the equipment supplied.

4UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

EN

2. AIR HANDLING UNIT FUNCTIONS

To create a comfortable home environment, you can adjust ventilation intensity and air temperature as well as to create a

weekly ventilation schedule. Various additional functions facilitate control of all ventilation processes and reduce electricity

consumption.

2.1. Air ow control

Fan speed of air handling units is adjusted by the selected air ow control method:

• CAV – constant air volume control. Fan speed is adjusted by measuring air ow and comparing it against the set value.

Fan rotates exactly at a speed required to reach the set air volume, regardless of pressure changes. For example, when

air lters get contaminated, the fan speed will be automatically increased to reach the same volume of air as during

operation with clean lters. In operating modes, the user sets a desired air volume for each fan separately. Air volume is

set and measured in m3/h or l/s.

• VAV – variable air volume control mode. This mode allows maintaining constant air pressure in ducts while the fan speed

is adjusting according to pressure changes in the ventilation system. Air pressure in ducts is measured with optional VAV

pressure sensors installed in supply and exhaust air ducts and connected to B6 and B7 terminals of the main controller

(see “Installation Manual”). User sets a desired air pressure value for supply and extracted air individually in operating

modes. Air pressure is set and measured in Pa.

• DCV – direct air volume control mode. This mode is quite similar to the CAV mode, but additionally allows adjustment

of fan speed by connecting a 0..10 V control signal to terminals B6 and B7 of the main board (see “Installation Manual”).

As the control signal voltage changes, fan speed is adjusted accordingly, i.e. 10V corresponds to the set air volume value,

whereas, 2V corresponds to 20% of the fan power.

Selection of air ow control is described in chapter “Control and Settings”.

2.2. Temperature control

Temperature in the air handling unit is maintained by measuring the actual temperature and comparing it to the user-

dened temperature. Then, depending on whether the supply air requires heating or cooling, heat exchanger or additional

heaters/coolers are activated. Available temperature control methods:

• Supply air temperature control – the unit supplies air of user-dened temperature.

• Extract air temperature control – the unit automatically selects the supply air temperature to ensure that the extract

air temperature is reached and maintained as quickly as possible. Room air temperature is measured by an integrated

extract air temperature sensor.

• Room temperature control – the unit automatically selects the temperature of supply air to ensure that the room

temperature is reached and maintained as measured by the sensor integrated in a remote controller. Control panel must

be installed in a room where temperature maintenance is required.

• Balance – Supplied air temperature will be maintained to be the same as extracted air temperature, therefore, selecting a

desired temperature is not possible. Extract air temperature is measured by an integrated extract air temperature sensor.

Selection of temperature control is described in chapter “Control and Settings”.

5

UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

2.3. Standard operating modes

4 standard operating modes are available on your air handling unit. Each operating mode has preset air volume and

desired temperature values:

MINIMALUS

Vėdinimo intensyvumas

20%

Pageidaujama

temperatūra

20

°C

NORMALUS

Vėdinimo intensyvumas

50%

Pageidaujama

temperatūra

20

°C

INTENSYVUS

Vėdinimo intensyvumas

70%

Pageidaujama

temperatūra

20

°C

MAKSIMALUS

Vėdinimo intensyvumas

100%

Pageidaujama

temperatūra

20

°C

AWAY NORMAL INTENSIVE BOOST

Ventilation

intensity 20% 50% 70% 100%

Set

temperature 20°C 20°C 20°C 20°C

These settings may be changed (see “Control and Settings”).

2.4. Special operating modes

4 special operating modes are available on your air handling unit. During activation, KITCHEN, FIREPLACE and OVERRIDE

modes are set for operation from 1 min. to 300 min. In HOLIDAY mode, operation time is set from 1 to 90 days or for a specic

date. KITCHEN, FIREPLACE and OVERRIDE modes may also be activated by short-cutting designated terminals on the main

board, i.e. by connecting a switch, cooker hood or a motion sensor (see “Installation Manual”). Each operating mode has

preset air volume and desired temperature values:

Tiekiamo oro intensyvumas

80%

Ištraukiamo oro intensyvumas

20%

Pageidaujama temperatūra

20

°C

VIRTUVĖ

Tiekiamo oro intensyvumas

60%

Ištraukiamo oro intensyvumas

50%

Pageidaujama temperatūra

20

°C

ŽIDINYS

Tiekiamo oro intensyvumas

80%

Ištraukiamo oro intensyvumas

80%

Pageidaujama temperatūra

20

°C

PIRMENYBĖ

Vėdinimo įrenginys kelis

kartus per dieną įsijungs

30-čiai minučių. Kitu laiku

vėdinimas bus išjungtas.

Vėdinimo intensyvumas

20%

Pageidaujama temperatūra

20

°C

ATOSTOGOS

KITCHEN FIREPLACE OVERRIDE HOLIDAYS

Intensity

of supplied air 80% 60% 80% Ventilation unit will turn on for 30 min-

utes several times a day. At other times,

the ventilation unit is switched o.

Ventilation intensity 20%.

Intensity

of extract air 20% 50% 80%

Set

temperature 20°C 20°C 20°C 20°C

These settings may be changed (see “Control and Settings”).

2.5. ECO mode

ECO – an energy saving mode intended for minimizing power consumption. Power consumption is reduced by turning

o heating/cooling devices, making maximum use of outdoor air or decreasing fan speed. During ECO mode:

• Electrical heater is blocked, all other external air heating/cooling devices are switched o.

• Rooms are cooled/heated with the outside air without a recuperator when the outside air temperature falls within the

set temperature range.

• When supply air temperature is below a set minimum value (in winter) or exceeds a maximum value (in summer), the unit

attempts to maintain the air temperature by decreasing ventilation intensity.

Setting the temperature range, switching o recuperation or heating/cooling devices may be done in the ECO mode

settings (see chapter “Control and Settings”).

6UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

EN

2.6. AUTO mode

During AUTO mode, ventilation intensity is adjusted by a weekly schedule or air quality in the premises, i.e. ventilation is

activated only when necessary or desired.

2.6.1. Weekly operation schedule

If you want the unit to operate when you need it, you can create a weekly operation schedule. The unit has 3 default

weekly operation schedules tailored to dierent situations. Also, you can create your own schedule:

Working week Oce Stay at home

At night the unit operates in AWAY op-

eration mode, and in the morning or

evening it switches to NORMAL opera-

tion mode.

The unit is switched o during the

working day.

The unit operates only during the work-

ing days: in NORMAL operation mode

until noon and in INTENSIVE mode in

the afternoon.

The unit is switched o during nights

and weekends.

The unit operates all the time: in AWAY

operation mode during the night and

in NORMAL operation mode during the

day.

Programs, times and days of a schedule may be changed (see chapter “Control and Settings”).

2.6.2. Air quality control function

Air quality control function activates ventilation only when necessary, i.e. when the air quality is poor. If the indoor air

quality is good, the unit will ventilate at minimum speed or stop. Air quality in the premises may be controlled by impurity

or humidity sensors connected to B8 and B9 terminals of the main board (see “Installation Manual”).

Air quality control function is not available inVAV air ow control mode (see“Air Flow Control”). In this

case, the unit will operate by a weekly operation schedule in AUTO mode.

As air impurity and humidity control methods slightly dier, the air quality control function is divided into:

• Impurity control

Impurity function is controlled via the following sensors:

CO2 – carbon dioxide concentration sensor [0...2000 ppm];

VOC – air quality sensor [0...100 %];

Air impurity function automatically selects ventilation intensity in the range of 20–70%, based on air quality readings. If

air pollution is within the user-dened limits, fans will operate at minimum speed; as level of pollution increases, the unit will

increase ventilation speed and supply more fresh air to the premises. It is also possible to stop the unit when air pollution is

low. For this purpose, change a minimum ventilation intensity limit to 0% (see “Control and Settings”). Then the unit will turn

on periodically (every 2 hours by default) to inspect the air quality, and will ventilate until pollution is reduced, if necessary.

Type of connected sensors and range of ventilation intensity may be modied (see “Control and Settings”).

• Humidity control

Humidity control function allows dehumidication of air in the premises. Possible ways of dehumidication:

1. If outdoor humidity is measured via an additional humidity sensor, air in the premises will be dehumidied when

humidity level outdoors is lower than indoors. Indoor humidity is monitored by a separate sensor connected to a

controller board or integrated in a control panel. In the settings: set sensor type RH and select one of the connected

sensors for measuring outdoor humidity (see “Control and Settings”). In AUTO mode fans are running at minimum

speed as long as the indoor humidity is lower than the setpoint (see “Impurity Control”). When humidity outdoors is

lower than indoors and dehumidication of the premises is necessary, the fan speed will be increased gradually and

drier air will be supplied.

7

UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

2. If no outdoor humidity sensor is used, “Humidity Control” function operates the same way as the “Impurity Control”

function but instead of an air quality sensor, optional humidity sensor connected to the controller or integrated in the

control panel is used.

3. If an external DX unit or a water cooler is used (activated in “Control Sequence Settings”), additional dehumidication

is possible by cooling supply air. In this case, the supply air temperature setpoint is ignored and colder but drier air is

supplied until the desired indoor humidity level is reached. If an outdoor humidity sensor is used and the outdoor air

is drier, the unit will attempt lowering the indoor humidity by supplying drier outdoor air before activating cooling

units. Dehumidication with cooling devices is possible both in AUTO and standard ventilation modes.

To use a DX unit or a water cooler for dehumidication of supply air, activate an option “Allow dehumidifying with

cooling” (see “Control Sequence Settings”). An option to enter a value for desired humidity will appear in the settings of

standard ventilation modes.

8UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

EN

3. CONTROL AND SETTINGS

Ventilation unit may be conveniently controlled via the following ways:

• Remote controller

• Mobile app

• Web browser

Air handling unit (based on its equipment) may have one of the following control panels:

C6.1 C6.2

3.1. Control panel C6.1

Panel with a colour touch-sensitive display. This control panel is designed for indication and changing of various func-

tions and settings of the unit. If the unit is connected to the mains, the control panel will display home screen or a screen

saver that you can switch o with a single tap. Touch-sensitive display reacts to soft taps, therefore, do not use any sharp

tools (screwdrivers or pens), also do not apply excessive force as it may damage the display.

16:30

NORMAL

ECO AUTO

16:30

30 % RH

22,0 °C

Screen saver Main screen

Function icons

Fan intensity

Icon of an activated mode

ECO

function

button

Time Menu

button

AUTO

function

button

9

UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

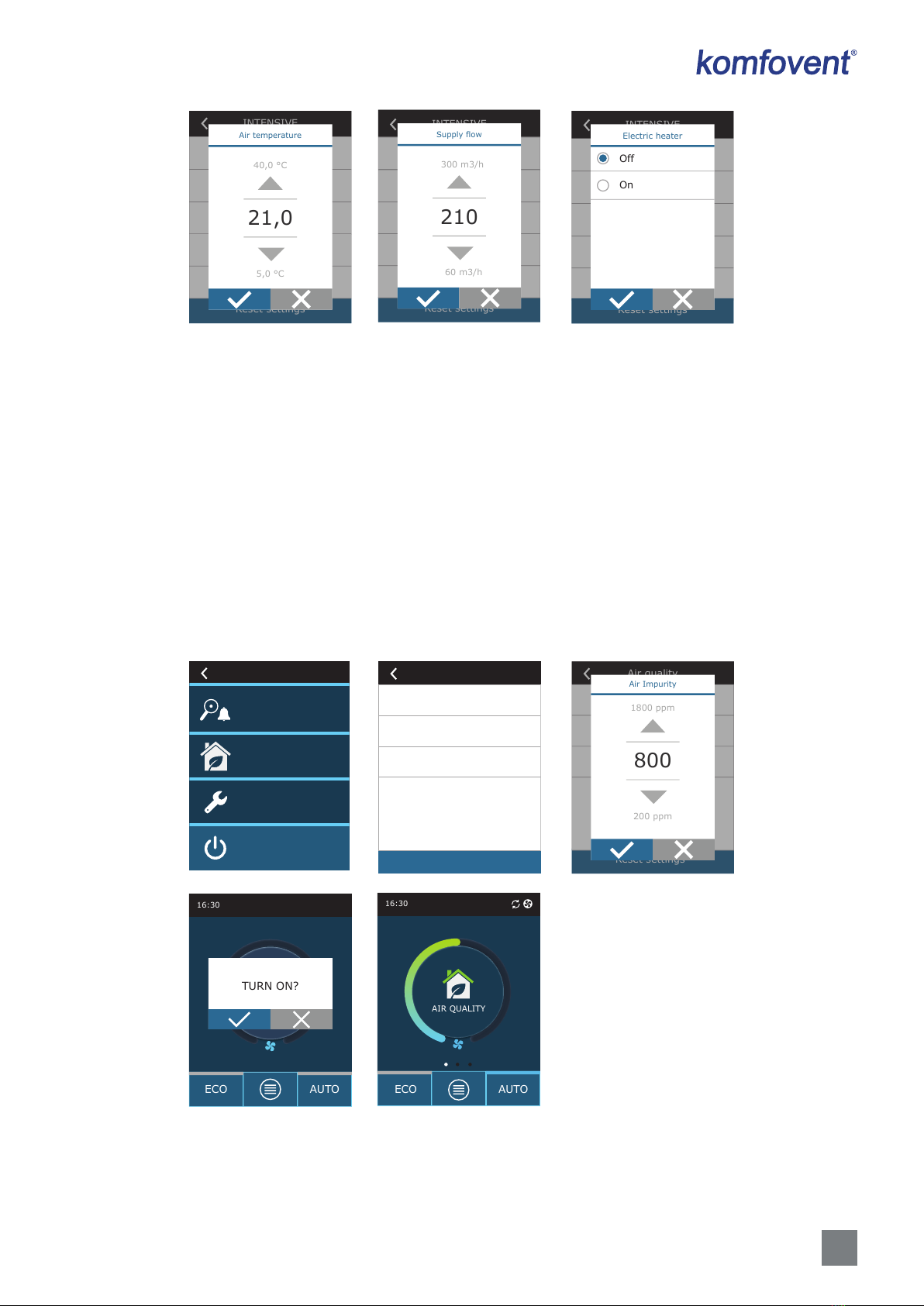

INTENSIVE

Reset settings

21,0

5,0 °C

40,0 °C

Overview

Scheduling

TURN OFF

Settings

Menu

Menu

window

Parameter modication

window

Parameter to be changed

Maximum possible value

Minimum possible value

Current setting

Increase

Decrease

ConrmReturn to a

previous window

Cancel

Air temperature

Displayed symbols on the panel

Fan operation

Energy recovery operation

Air heater operation

Air cooler operation

There is a heating demand, but it is

being blocked by the ECO mode

There is a cooling demand, but it is

being blocked by the ECO modes

ECO mode on. Air ow reduction.

ECO mode on. Free cooling

operation.

ECO mode on. Free heating

operation.

Alarm signal

(see the troubleshooting section)

Supply air

Exhaust air

Outside air temperature

Air lters

Instant heat recovery of the air

handling unit

Instant power consumption of the

air handling unit

10 UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

EN

3.1.1. Parameter overview

Swipe the main window to the side to see various parameters: air ow, temperatures, lter contamination, energy recov-

ery and power consumption.

16:30

NORMAL

ECO AUTO

16:30

OVERVIEW

20,0 °C 21,7 °C 10,4 °C

210 m3/h210 m3/h 17 %

ECO AUTO

16:30

Heat recovery

82%

0,87 kW

4,23 kW

1,20 kW

Power consumption

ECO AUTO

See menu section “Overview” for more parameters.

Overview

Scheduling

TURN OFF

Settings

Menu

Detailed information

Efficiency & consumption

Alarms

Energy counters

Overview

3.1.2. Turning on

The unit must be switched on to operate by a selected ventilation mode, schedule or air quality.

To turn on your air handling unit:

1. Press the ON/OFF button in the centre of the home screen.

2. Conrm the message that appears.

3. A symbol will appear in the centre of the home screen indicating an operating mode which will start soon.

16:30

IŠJUNGTA

ECO AUTO

TURN ON?

16:30

NORMAL

ECO AUTO

16:30

OFF

ECO AUTO

11

UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

3.1.3. Turning o

If you want your device to stop working, regardless the operation schedule and other functions, you can turn it o.

To turn o the device:

1. Press “Menu” button at the bottom of the home screen.

2. Press the ON/OFF button at the bottom of the menu window.

3. Conrm the message that appears.

4. Press a return icon at the top of the window to return to the main screen.

Overview

Scheduling

TURN OFF

Settings

Menu

Overview

Planavimas

TURN OFF

Settings

Menu

TURN OFF?

Overview

Scheduling

TURN ON

Settings

Menu

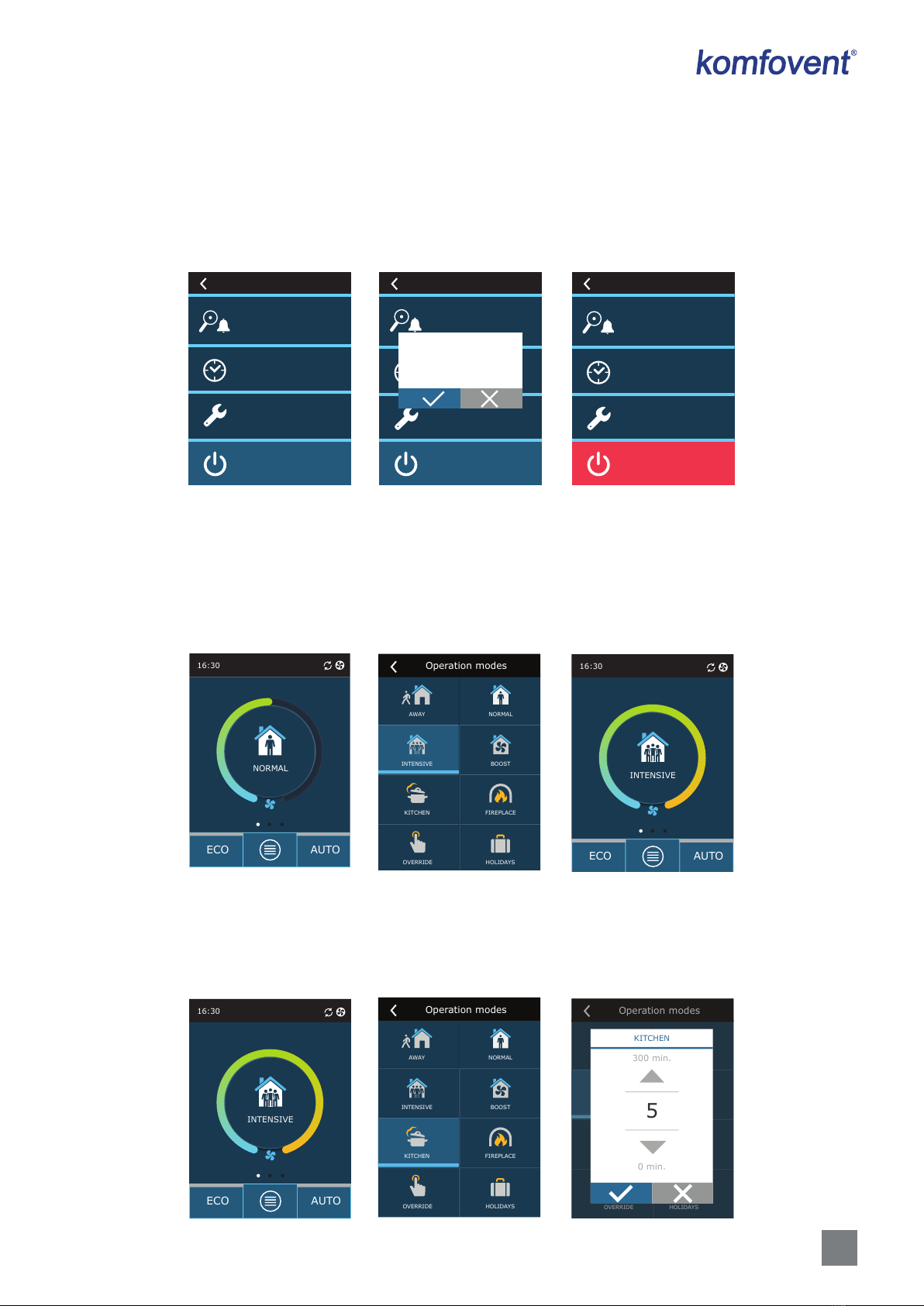

3.1.4. Mode change

To turn on a standard ventilation mode:

1. Press an icon indicating the current operation mode in the middle of the home screen.

2. Select and press a desired operation mode.

3. An icon for the selected operation mode appears in the middle of the home screen.

16:30

NORMAL

ECO AUTO

INTENSIVE

NORMALAWAY

BOOST

HOLIDAYS

KITCHEN

OVERRIDE

FIREPLACE

Operation modes

16:30

INTENSIVE

ECO AUTO

To turn on a special ventilation mode:

1. Press an icon indicating the current operation mode in the middle of the home screen.

2. Select and press a desired special operation mode.

3. Use the arrows to select desired operation duration and press to conrm.

4. Press the return icon at the top of the screen to return to the home screen.

16:30

INTENSIVE

ECO AUTO

INTENSIVE

NORMALAWAY

BOOST

HOLIDAYS

KITCHEN

OVERRIDE

FIREPLACE

Operation modes

INTENSYVUS

NORMALUSMINIMALUS

MAKSIMALUS

HOLIDAYS

VIRTUVĖ

OVERRIDE

ŽIDINYS

Operation modes

KITCHEN

5

0 min.

300 min.

12 UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

EN

When operating in a special mode, air ow is maintained by CAV method, regardless the selected air ow control method.

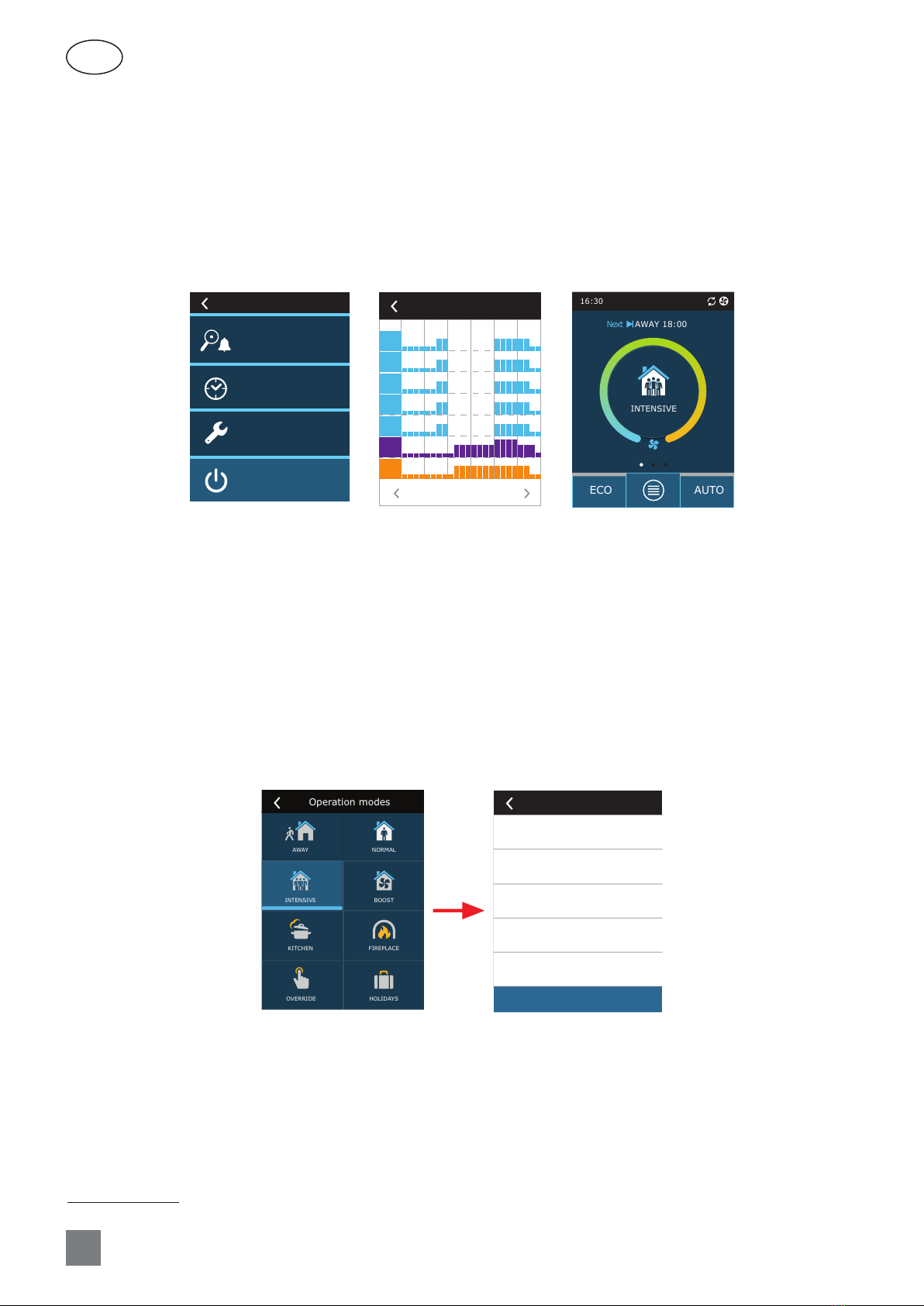

To activate ventilation by a weekly schedule1:

1. Press “Menu” button at the bottom of the home screen.

2. Press “Planning” button in the menu window.

3. Use the arrows at the bottom of the window to select a desired weekly schedule.

4. Press a return icon at the top of the window twice to return to the home screen.

5. Press AUTO button to activate scheduled ventilation.

6. Information about upcoming changes in the schedule is displayed at the top of the screen.

Overview

Scheduling

TURN OFF

Settings

Menu Scheduling

WORKING WEEK

0 4 8 12 16 20 24

Mo

Tu

We

Th

Fr

Sa

Su

16:30

INTENSIVE

ECO АUTO

AWAY 18:00Next

3.1.5. Air quantity and temperature settings

You can set air ow for supply and exhaust air, desired temperature and turn o/on an electric heater for each ventilation

mode. If turned o, the heater will not turn on even when the desired temperature is not reached. If turned on, the heater

will operate only when a heat exchanger alone cannot reach the set temperature.

To change the ventilation mode settings:

1. Press an icon indicating the current operation mode in the middle of the home screen.

2. Press a desired mode button and hold it for 5 seconds.

3. Press a parameter you want to change.

4. Use the arrows to select a desired value and press to conrm.

5. Press a return icon at the top of the screen to return to the home screen.

INTENSIVE

NORMALAWAY

BOOST

HOLIDAYS

KITCHEN

OVERRIDE

FIREPLACE

Operation modes

5 s

Supply flow

210 m3/h

Extract flow

210 m3/h

Electric heater

On

Air temperature

20,0 °C

INTENSIVE

Reset settings

1 Ventilation by a weekly schedule is not possible when air quality control function is activated.

13

UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

Tiekiamas srautas

210 m3/h

Šalinamas srautas

210 m3/h

Elektrinis šildytuvas

Įjungta

Oro temperatūra

20,0 °C

INTENSIVE

Reset settings

21,0

5,0 °C

40,0 °C

Air temperature

Tiekiamas srautas

210 m3/h

Šalinamas srautas

210 m3/h

Elektrinis šildytuvas

Įjungta

Oro temperatūra

20,0 °C

INTENSIVE

Reset settings

210

60 m3/h

300 m3/h

Supply flow

INTENSIVE

Reset settings

Electric heater

Off

On

3.1.6. Air quality control mode activation and settings

If air quality sensors are connected to the main board or impurity control/moisture control function is activated (see “Ad-

vanced Settings”), button “Scheduling” appears instead of “Air quality” button. For more information about the air quality

control function see chapter “Air Quality Control Functions”.

To enter desired limits and turn on ventilation by air quality:

1. Press “Menu” button at the bottom of the home screen.

2. Press “Air quality” button.

3. Select a parameter you want to change.

4. Use the arrows to select a desired value and press to conrm.

5. Press a return icon at the top of the screen to return to the home screen.

6. Ventilation by air quality is turned on by pressing AUTO button while the unit is operating in any ventilation mode.

7. If the unit was stopped, pressing AUTO button will call up a message, the conrming of which will activate ventilation

by air quality.

Overview

Air quality

TURN OFF

Settings

Menu

Air Impurity

800 ppm

Air temperature

20,0 °C

Electric heater

On

Air quality

Reset settings

Air quality

Reset settings

Air Impurity

800

200 ppm

1800 ppm

16:30

IŠJUNGTA

ECO AUTO

TURN ON?

16:30

AIR QUALITY

ECO AUTO

14 UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

EN

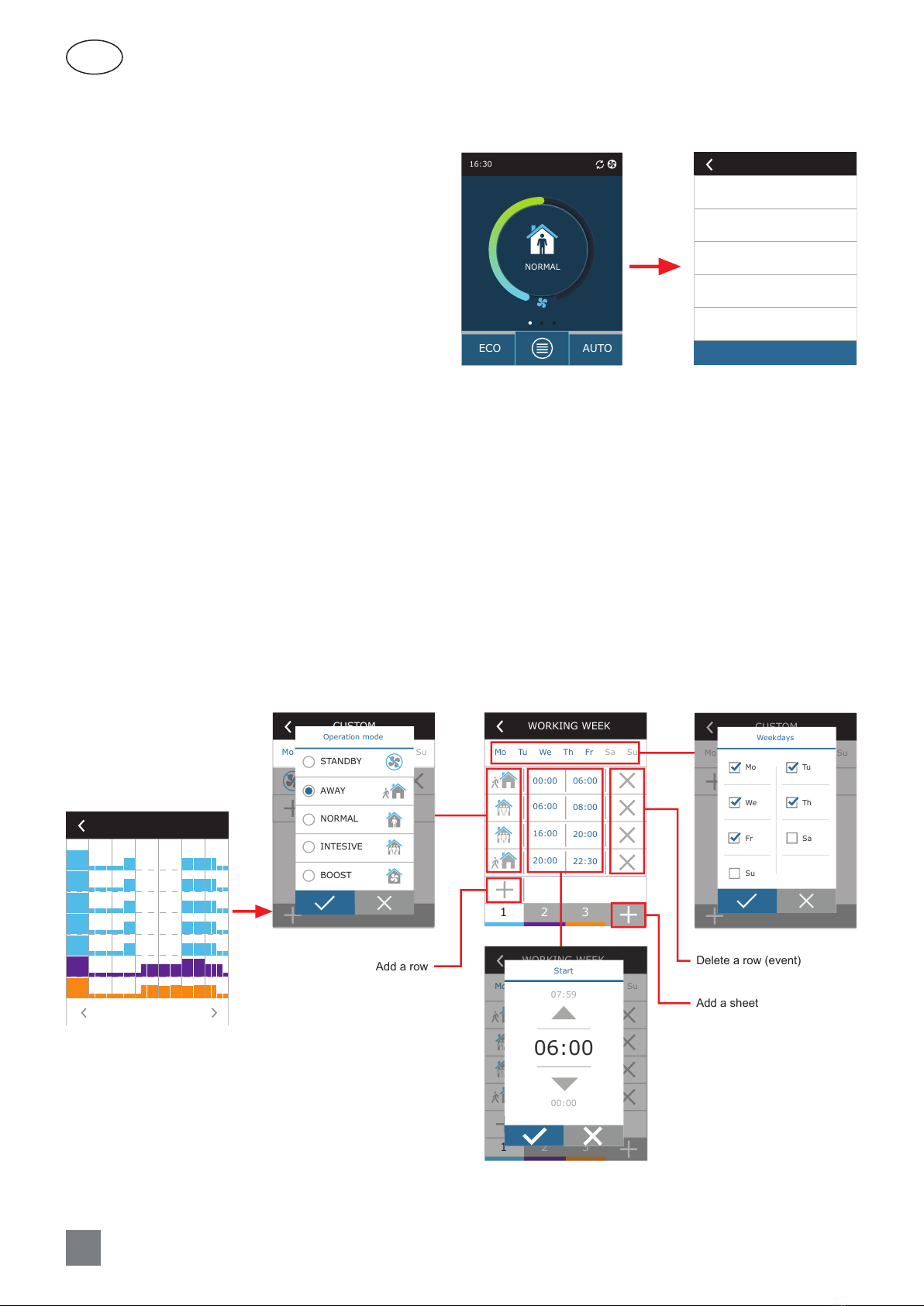

3.1.8. Creating a weekly operation schedule

You can modify ventilation modes, operation time and day for all default operation schedules.

To modify settings of a default schedule:

1. Select a weekly schedule as shown in Chapter “Mode Change”.

2. Press the centre of the schedule window and hold for 5 seconds.

3. By pressing the weekday row you can select which days of the week this schedule sheet is valid for.

4. Pressing the ventilation mode icon on the left will allow selecting a desired ventilation mode.

5. Press time of a specic ventilation mode to change the operation start and end times.

6. Press X on the right to delete a row (ventilation mode and operation start/end times) from a schedule.

7. To add an additional row, press + under the last scheduled row (maximum 5 rows). If the last event ends at 24:00, you

will have to delete it to add a new row.

8. To add another sheet, press + at the bottom of the window (maximum 4 sheets).

Scheduling

WORKING WEEK

0 4 8 12 16 20 24

Mo

Tu

We

Th

Fr

Sa

Su

WORKING WEEK

Mo Tu We Th Fr Sa Su

00:00 06:00

08:00

06:00

20:00

16:00

22:30

20:00

12 3

WORKING WEEK

Mo Tu We Th Fr Sa Su

00:00 06:00

08:00

06:00

20:00

16:00

22:30

20:00

12 3

Start

06:00

00:00

07:59

CUSTOM

Mo TU We Th Fr Ša Su

00:00 00:01

Operation mode

STANDBY

AWAY

NORMAL

INTESIVE

BOOST

CUSTOM

Mo Tu We Th Fr Sa Su

Weekdays

Tu

Th

Sa

Mo

We

Fr

Su

Delete a row (event)

Add a sheet

Add a row

5 s

3.1.7. ECO mode activation and settings

ECO mode may be activated in any ventilation mode

by pressing ECO button at the bottom of the home screen.

For more information about the ECO mode see chapter “Air

Quality Control Functions”.

To change the ECO mode settings:

1. Press ECO button and hold it for 5 seconds.

2. Press a parameter you want to change.

3. Select a desired option or set a desired value using

arrows.

4. Conrm your selection.

5. Press a return icon at the top of the window to re-

turn to the home screen.

16:30

NORMAL

ECO AUTO

5 s

Heater blocking

On

Cooler blocking

On

Free cooling

On

Min. supply air temperature

15,0 °C

Max. supply air temperature

25,0 °C

ECO

Reset settings

15

UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

To create a weekly operation schedule:

1. Select a weekly schedule “My week” as shown in Chapter “Mode Change”.

2. Press the centre of the schedule window and hold for 5 seconds.

3. Press the weekday row to select which days of the week this schedule sheet is valid for.

4. Press + symbol and add a new row.

5. Press the ventilation mode icon on the left to select a desired ventilation mode. There is no need to include a STAND-

BY mode in the schedule for intervals when the unit will not operate. The unit will be stopped during any intervals for

which no ventilation mode is assigned.

6. Set the start and end time for a ventilation mode. If you need 24-hour ventilation, set the start time for 0:00 and the

end time for 24:00.

7. To add an additional row, press + under the last scheduled row (maximum 5 rows). If the last event ends at 24:00, you

will have to delete it to add a new row.

8. To add another sheet, press + at the bottom of the window (maximum 4 sheets).

Scheduling

CUSTOM

0 4 8 12 16 20 24

Mo

Tu

We

Th

Fr

Sa

Su

CUSTOM

Mo Tu We Th Fr Sa Su

CUSTOM

Mo Tu We Th Fr Sa Su

Weekdays

Tu

Th

Sa

Mo

We

Fr

Su

5 s

CUSTOM

Mo Tu We Th Fr Sa Su

CUSTOM

Mo Tu We Th Fr Sa Su

00:00 00:01

1

CUSTOM

Mo Tu We Th Fr Sa Su

00:00 00:01

Operation mode

STANDBY

AWAY

NORMAL

INTESIVE

BOOST

CUSTOM

Mo Tu We Th Fr Sa Su

00:00 00:01

Start

06:00

00:00

23:59

16 UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

EN

3.1.9. Main settings

In the menu point SETTINGS you can modify the main user interface settings:

Overview

Scheduling

TURN OFF

Settings

Menu

Language

English

Flow units

m3/h

Panel lock

None

Panel sound

Time/Date

Screen saver

On

Settings

Language – set a desired control panel language using arrows.

Flow measurement units – select units for air ow measurement.

Settings

Language

English

Русский

Lietuvių

Settings

Flow units

m3/h

l/s

Screen saver – turn the screen saver on/o. Screen saver activates when a control panel is not used for longer than 1 min.

You may select brightness of a screen saver, as well as settings and the order in which they are displayed. If a screen saver is

deactivated, the control panel display turns o if not used for longer than 1 min. Tap a screen to wake-up.

Panel lock – partial or full panel lock is available. Partial lock allows turning on/o an air handling unit and selecting

desired ventilation mode but does not allow any ventilation settings to be changed. Full panel lock prevents the user from

using the control panel. To unlock the panel, you have to enter your four-digit PIN code. When the lock is on, the panel will

lock every time the screen saver is activated.

Activate

Brightness

50%

Row 2

Panel temperature

Row 3

Panel humidity

Row 1

Time

Screen saver

Kalba

Lietuvių

Srauto vienetai

m3/h

Pulto užraktas

Nėra

Pulto garsas

Ekrano užsklanda

Įjungta

Settings

Panel lock

None

Partial

Full

17

UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

Panel sound – turning on/o touch and message sounds.

Time/Date – setting the time and date that are used for a weekly operation schedule or other functions.

Touch sound

Click

Alarms sound

On

Panel sound

Time

14:02

Month/Day

12/10

Year

2018

Time/Date

3.1.10. Advanced settings

To access the advanced settings, press and hold the SETTINGS button for 5 seconds.

5 s

Overview

Scheduling

TURN OFF

Settings

Menu

Temperature control

Flow control

Control sequence

Connectivity

Air quality control

Advanced settings

1/ 2

Clean filters calibration

Reset settings

Advanced settings

2/ 2

Temperature control – select a method for temperature control (see Chapter 2.2).

Temperature control

Supply

Temperature control

Temperatūros palaikymas

Tiekimas

Temperature control

Temperature control

Supply

Extract

Room

Balance

18 UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

EN

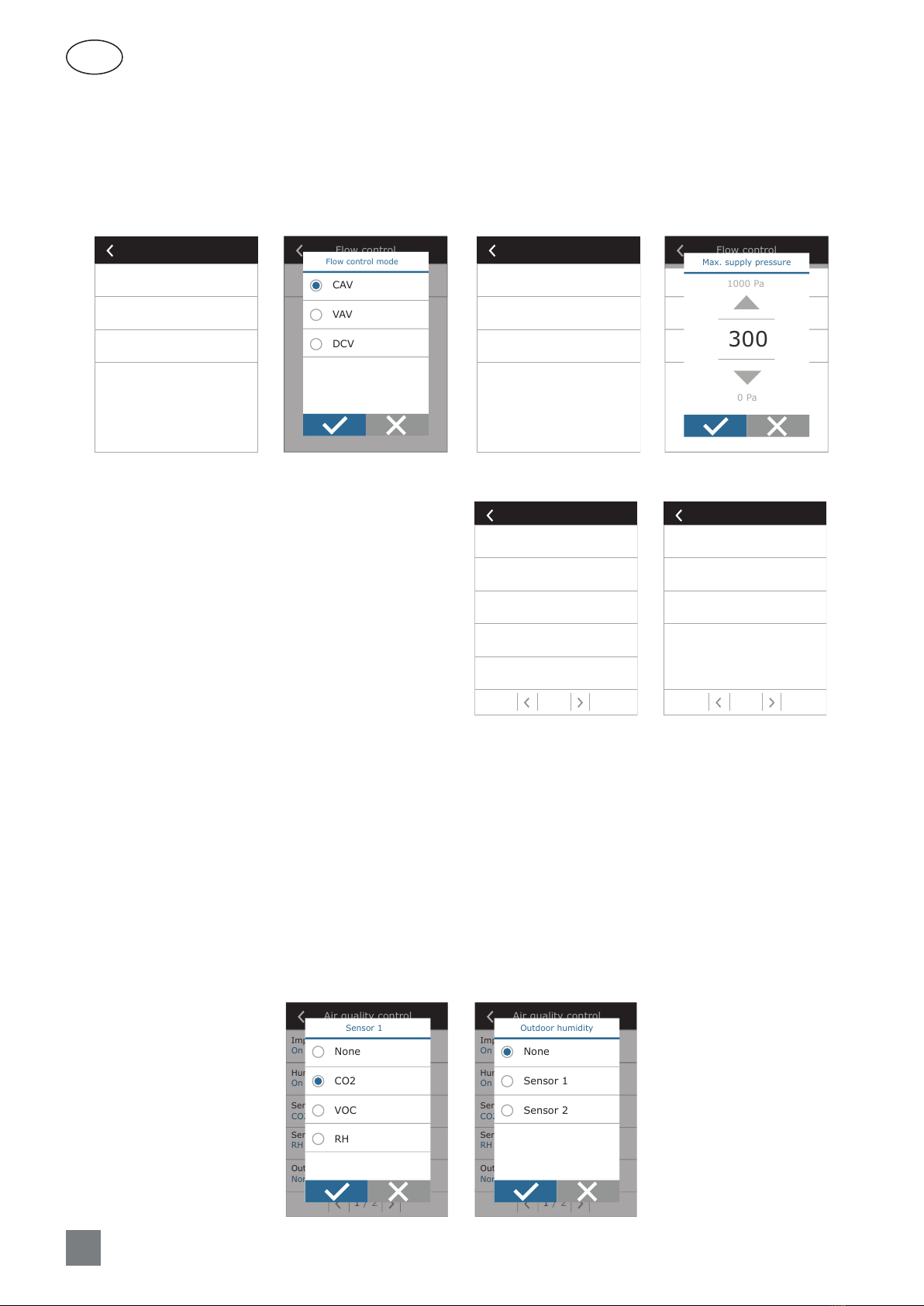

Flow control – select a method for air ow control (see Chapter 2.1). Selected CAV or DCV air ow control allows additional

corrections of supply and extract air measurements, when the measured air volume does not match the actual one. This may

also be due to design features of the duct system, for example, wrong diameter ducts, excessive number branches or elbows,

or installation without following the installation recommendations. When a VAV mode is selected, a measurement range

of pressure sensors connected to the main board must be additionally entered (see “Installation Manual”), i.e. maximum

pressure Pa that the sensor is measuring by 10V output (measurement range is specied in the VAV sensor manual).

Flow control mode

CAV

Supply flow correction

0 m3/h

Extract flow correction

0 m3/h

Flow control

Flow control

Flow control mode

CAV

VAV

DCV

Flow control mode

VAV

Max. supply pressure

300 Pa

Max. extract pressure

300 Pa

Flow control

Srauto palaikymo režimas

VAV

Maks. tiekiamo oro slėgis

300 Pa

Maks. šalinamo oro slėgis

300 Pa

Flow control

Max. supply pressure

300

0 Pa

1000 Pa

• Impurity control – turning on/o an impurity control function. At least one CO2 or VOC sensor must be connected to the

controller board to activate this function (see Chapter 2.6.2.). If ventilation by a weekly schedule is required, this function

must be turned o.

• Humidity control – turning on/o a humidity control function. Humidity control function requires a humidity sensor. If

no humidity sensor is connected to the controller board, sensor integrated in a control panel will be used for this purpose

(see Chapter 2.6.2.).

• Sensor 1 – specify the type of the sensor connected to a terminal B8 (see “Installation Manual”). If this sensor is not

available, select “None”.

• Sensor 2 – specify the type of the sensor connected to a terminal B9 (see “Installation Manual”). If this sensor is not

available, select “None”.

• Outdoor humidity – this option appears when one of the sensors is of RH type (humidity sensor). If any of the connected

sensors are installed in the outdoor air ow, specify which one. If none of the installed humidity sensors measure the

outside humidity, select “None”.

Air quality control

1/ 2

Impurity control

On

Humidity control

On

Sensor 1

CO2

Sensor 2

RH

Outdoor humidity

None

Sensor 1

None

CO2

VOC

RH

Air quality control

1/ 2

Impurity control

On

Humidity control

On

Sensor 1

CO2

Sensor 2

RH

Outdoor humidity

None

Outdoor humidity

None

Sensor 1

Sensor 2

Air quality control – here you can activate and set-up

air quality control which will be used in AUTO mode (see

Chapter 2.6.2).

Air quality control

1/ 2

Impurity control

On

Humidity control

On

Sensor 1

CO2

Sensor 2

RH

Outdoor humidity

None

2/ 2

Air quality control

Minimum intensivity

0 %

Maximum intensivity

70 %

Check period

2h

19

UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

• Minimum intensity – select ventilation intensity at which the unit will operate when air quality (impurity or humidity) is

good. If 0% is selected, the unit will stop when air impurity level is low.

• Maximum intensity – select ventilation intensity limit, under which the unit will operate when air quality (impurity or

humidity) exceeds a dened value.

• Check period – specify how often the unit shall turn on to check air quality, when minimum intensity is set to 0%.

Control sequence – here you can activate additionally connected duct-mounted heating or cooling devices (see

“Installation Manual”) that will operate only when a heat exchanger or electrical heater alone cannot reach a desired

temperature.

Control sequence

1/ 2

Stage 1

Electric heater

Stage 2

External coil

Stage 3

None

External coil type

Cold water

Icing protection

On

2/ 2

Control sequence

Indoor humidity

Auto

Allow dehumidifying with cooling

Off

Numbers indicate the order of activation. All units have an integrated electrical heater, therefore it is factory-assigned as

Stage 1. You can also assign an “external coil” (duct-mounted water heater/cooler) or an “external DX unit” (direct evaporation

heat exchanger) as a stage. If an external coil is selected, you also must specify its type: “Hot water” (used for heating), “Cold

water” (used for cooling) or AUTO (both for heating and cooling). If AUTO type is selected, heating or cooling operations are

decided by an external signal connected to the controller board terminals (see “Installation Manual”). If additional heating/

cooling devices are not available, you do not want to use them or an electrical heater, select “None”.

Stage 1

None

Electric heater

External coil

External DX unit

Control sequence

1/ 2

Stage 1

Electric heater

Stage 2

External coil

Stage 3

None

External coil type

Cold water

Icing protection

On

External coil type

Hot water

Cold water

Auto

If you turn o an electric heater and do not activate a duct-mounted heater, the desired air

temperature may not be reached when the outside air is cold.

20 UAB KOMFOVENT we reserve the right to make changes without prior notice

C6M_GUIDE2-19-04

EN

• Antifreeze protection – this setting is only available in units with counter-ow plate heat exchangers. These units are

equipped with electric pre-heaters which heat the outdoor air and protect a heat exchanger from freezing. Power of a

heater is regulated according the outside air temperature, indoor humidity and actual ow of ventilated air. Integrated

electric pre-heater operates on demand only when there is a risk of heat exchanger to freeze. Under very low indoor

humidity conditions, it is unlikely that the heat exchanger would freeze even at very low outdoor temperatures.

The following antifreeze protection settings are available:

ON – automatic protection with an integrated pre-heater is activated by default.

OFF – protection may be switched o, but the unit will also be turned o when the outside air temperature drops below

-4 °C.

External coil – when an external heater, connected to AUX terminals of the main board, is used instead of an integrated

pre-heater (see “Installation Manual”).

• Indoor humidity – this setting is necessary for estimating power of a pre-heater.

Possible settings:

Auto – indoor humidity is set automatically using an integrated humidity sensor and/or external humidity sensors

connected to B8 and B9 terminals of the controller (see “Installation Manual”).

10...90 % – setting a xed indoor humidity value is possible when a control panel is installed in inappropriate location (or

is not used) and no outside humidity sensors are connected.

Control sequence

1/ 2

Stage 1

Electric heater

Stage 2

External coil

Stage 3

None

External coil type

Cold water

Icing protection

On

Off

On

External coil

Icing protection

2/ 2

Control sequence

Indoor humidity

Auto

Allow dehumidifying with cooling

Off

Indoor humidity

Auto

10 %RH

90 %RH

Wrong value of indoor humidity may cause antifreeze protection to malfunction and a counter-ow

heat exchanger to freeze.

• Allow dehumidication with cooling –this setting must be enabled to use a DX unit or duct-mounted water cooler to

dehumidify the supply air. An option to enter a value for desired humidity will appear in the settings of standard ventila-

tion modes (see Chapter 2.6.2).

Connectivity – you can congure your PC network settings for remote use via web browser: IP address and subnet mask.

You may also change other network parameters, if necessary: Gateway and BACnet ID. DHCP option automatically assigns a

free IP address in the local network (do not use this option if you connect your computer directly to the unit).

Connectivity

IP address

192. 168. 0. 60

Subnet mask

255. 255. 0. 0

Gateway

192. 168. 0. 1

BACnet ID

60

DHCP

Other manuals for DOMEKT series

4

This manual suits for next models

21

Table of contents

Other Komfovent Fan manuals

Komfovent

Komfovent Verso Pro 2 Series User manual

Komfovent

Komfovent DOMEKT RHP 400 U-2,2/1.4 User manual

Komfovent

Komfovent KOMPAKT REGO Series User manual

Komfovent

Komfovent DOMEKT ReCU 300/350/450VE(W)-B-AC/EC Manual

Komfovent

Komfovent DOMEKT ReGO 200VEW-BK User manual

Komfovent

Komfovent DOMEKT C8 automation User manual

Komfovent

Komfovent DOMEKT ReGO 200VE-B Manual

Komfovent

Komfovent VERSO Pro S Manual

Komfovent

Komfovent VERSO Pro S Manual