Komfovent DOMEKT R 200 V Manual

DOMEKT

EN Installation and service Manual

UAB AMALVA we reserve the right to make changes without prior notice 3

D2-18-01

This symbol indicates that this product is not to be disposed of with your household waste, according to the

WEEE Directive (2002/96/EC) and your national law. This product should be handed over to a designated

collection point, or to an authorised collection site for recycling waste electrical and electronic equipment (EEE).

Improper handling of this type of waste could have a possible negative impact on the environment and human

health due to potentially hazardous substances that are generally associated with EEE. At the same time, your

cooperation in the correct disposal of this product will contribute to the effective usage of natural resources. For

more information about where you can drop off your waste equipment for recycling, please contact your local city

ofce, waste authority, approved WEEE scheme or your household waste disposal service.

Content

1. SAFETY REQUIREMENTS ............................................................................................................................ 4

2. TRANSPORTATION........................................................................................................................................ 4

3. BRIEF DESCRIPTION OF THE UNIT ........................................................................................................... 5

4. INSTALLATION ............................................................................................................................................. 12

4.1. Condensate Drain Connections ............................................................................................................... 16

4.1.1. Water trap installation for a unit section mounted on the suction side........................................... 17

4.1.2. Water trap installation for a unit section mounted on the pressure side ........................................ 17

4.2. Heating coil connection............................................................................................................................ 24

4.3. Ductwork .................................................................................................................................................. 24

4.4. Final Inspection........................................................................................................................................ 25

5. MAINTENANCE............................................................................................................................................. 25

6. TECHNICAL INFORMATION ....................................................................................................................... 26

EN

UAB AMALVA we reserve the right to make changes without prior notice

4

D2-18-01

1. SAFETY REQUIREMENTS

• To avoid accidents and/or unit damage, only a trained technician must

carry out the connection.

• The appropriate Personal Protective Equipment (PPE) attire is worn

relative to the operation being carried out.

• Electrical equipment is rated, connected and earthed in accordance

with CE regulations.

The air handling unit must be plugged in to an electrical outlet (with earth), which is in good order and corre-

sponds with all requirements of electric safety. Before starting any operations inside the unit, make sure that

the unit is switched off, and the power cable is unplugged.

• Earth must be installed according EN61557, BS 7671.

• The unit should be installed according to Installation and Maintenance

Manual.

• Before starting the unit, check correct position of air lters.

• Service maintenance should be carried out only in conformity with the

instructions specied herein below.

• If main cable is damaged, only manufacturer, service team or trained

technician must change it in order to avoid accidents.

2. TRANSPORTATION

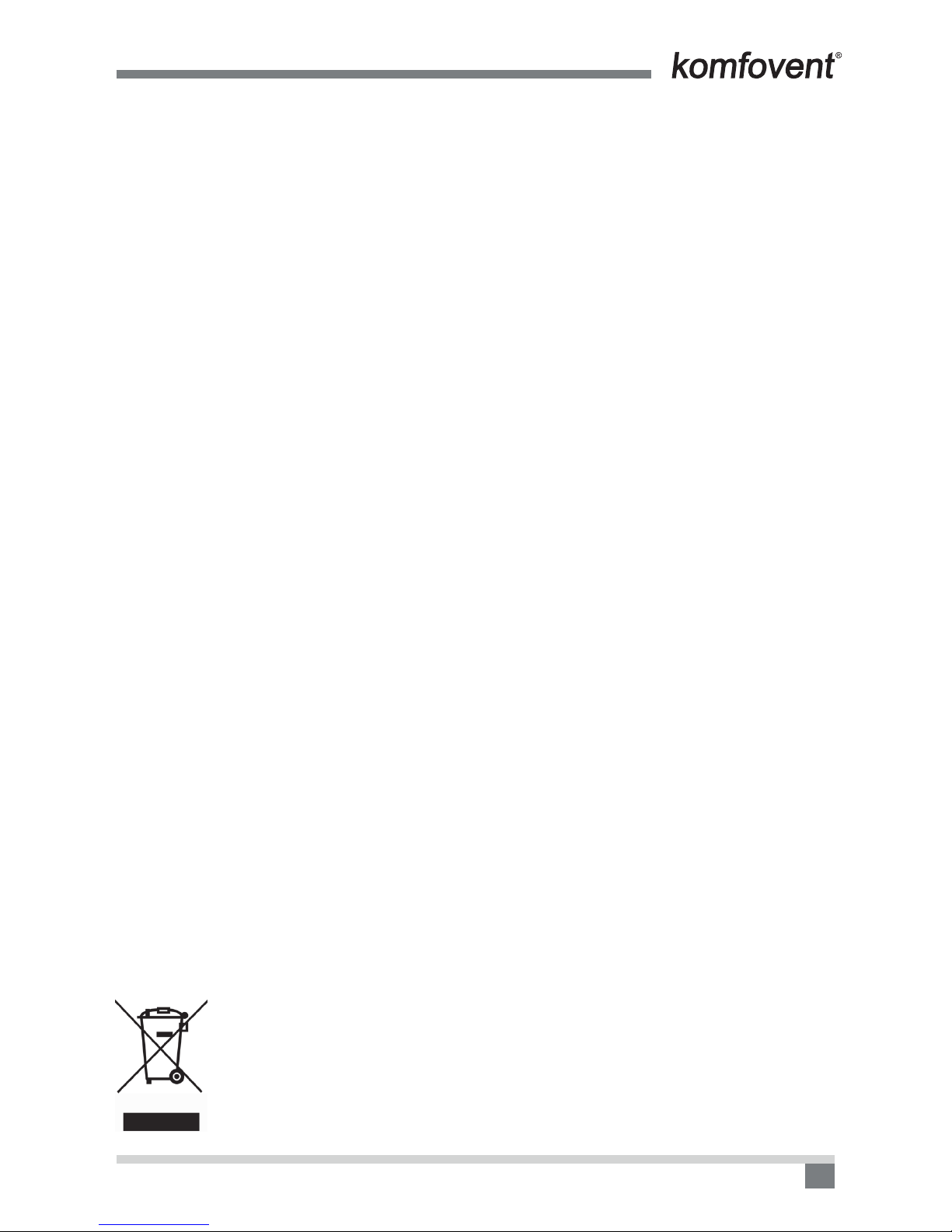

The air handling units are ready for transit and storage (1 Picture). The unit is packed to prevent damage of the

external and internal parts of the unit, dust and moisture penetration.

Corners of the air handling units are protected against the damage – protective corners are used. The en-

tire unit is wrapped up in protective lm. For transit or storage, units are mounted on timber pallets. The unit is

fastened to the pallet with polypropylene packing tape over protective corners.

Vertical and horizontal units ready for transit and storage

1 Picture

UAB AMALVA we reserve the right to make changes without prior notice 5

D2-18-01

When unit is loaded or unloaded by crane, cargo rope is fastened in its designated places.

Forklift truck or hand pallet truck can transport air handling unit as it is shown (2 a, b, c Pictures).

Vertical and horizontal unit transportation by forklift truck, hand pallet truck or crane

2 a Picture 2 c Picture

2 b Picture

2 a Unit is transported by forklift truck on a wooden pallet;

2 b Unit is transported by hand pallet truck on a wooden pallet;

2 c Unit is lifted by crane on a wooden pallet.

The unit should be examined upon receipt, to ensure that no visible damage has occurred during transit, and

the advice note checked to ensure that all items have been received. If damage or delivery shortages are disco-

vered, the carrier should be immediately informed. AMALVA should be notied within three days of receipt, with

a written conrmation sent within seven days. AMALVA can accept no responsibility for damage by unloading

from carrier or for subsequent damage on site.

If the unit is not to be installed immediately, it should be stored in a clean, dry area. If stored externally, it

should be adequately protected from the weather.

3. BRIEF DESCRIPTION OF THE UNIT

• The air handling units are intended for ventilation of small and medium-sized spaces (eg. single family

houses, ofces, etc.), having operating ambient temperature and relative humidity. The unit is intended to

be installed in the domestic or non residential premises. Mineral wool is used for thermal insulation and

sound attenuation. Units cover panels are 25–50 mm thick. As standard, the unit is designed for indoor

placement. In cold, wet rooms possible icing or condensation on the housing inside and outside. The op-

erating temperature range for the unit is -30 °C ... +40 °C, outdoor air temperature. Extracted indoor air

temperature +10 – +40 °C, relative humidity (non-condensing) 20–80 %.

• The air handling unit is not to be used to transport solid particles, even not in areas where there is a risk of

explosive gases.

• The units are equipped with a rotary heat exchanger or with a plate heat exchanger (may be replaced with

summer cassette, when recuperation is needless), air lters, an electric or water heater, fans and automa-

tion control system, to ensure safe and efcient operation of the unit.

• Before you open the door, the unit must be switched off and the fans must have been given time to stop (up

to 3 minutes).

• The unit contains heating elements that must not be touched when they are hot.

• We recommend to leave air handling unit in working mode (minimum 20 percent of power) during the rst

operation year. Due to moisture in building constructions, condensation may occur inside and outside the

air handling unit. Continuous operation of the equipment will signicantly reduce the risk of condensation.

EN

UAB AMALVA we reserve the right to make changes without prior notice

6

D2-18-01

• To maintain a good indoor climate, comply with regulations and, to avoid condensation damage, the unit

must never be stopped apart from during service/maintenance or in connection with an accident.

• If the unit is placed in spaces with high humidity, condensation might occur on the surface of the unit when

outdoor temperatures are very low.

• Under conditions, when the outdoor air temperature is low and humidity is high, risk of heat exchanger

frosting may appear. For this reason anti-frost protection function is foreseen in the controller of the Kom-

fovent air handling units. Depending on the type of the recovery, different methods of anti-frost protection

are available: cold air by-passing, or / and supply air fan speed reducing. For extremely low outdoor air

temperature the duct mounted preheater is recommended. Counter cross ow heat exchanger is the mostly

sensitive for low outside air temperatures, as the risk of frosting appears in the temperature range from

0 to -5 °C and below. Standard aluminium cross-ow plate heat exchanger has better features, as the risk

of freezing appears only at -10 °C. The lowest risk and the highest resistance to cold outside air is a com-

petitive feature of the rotary heat exchanger, as it is not freezing even at the temperatures of -30 °C if the

humidity level of the air is appropriate.

• Selecting the management without pre-heater, but with cold air bypass the unit must be additionally

equipped with a secondary duct mounted heater.

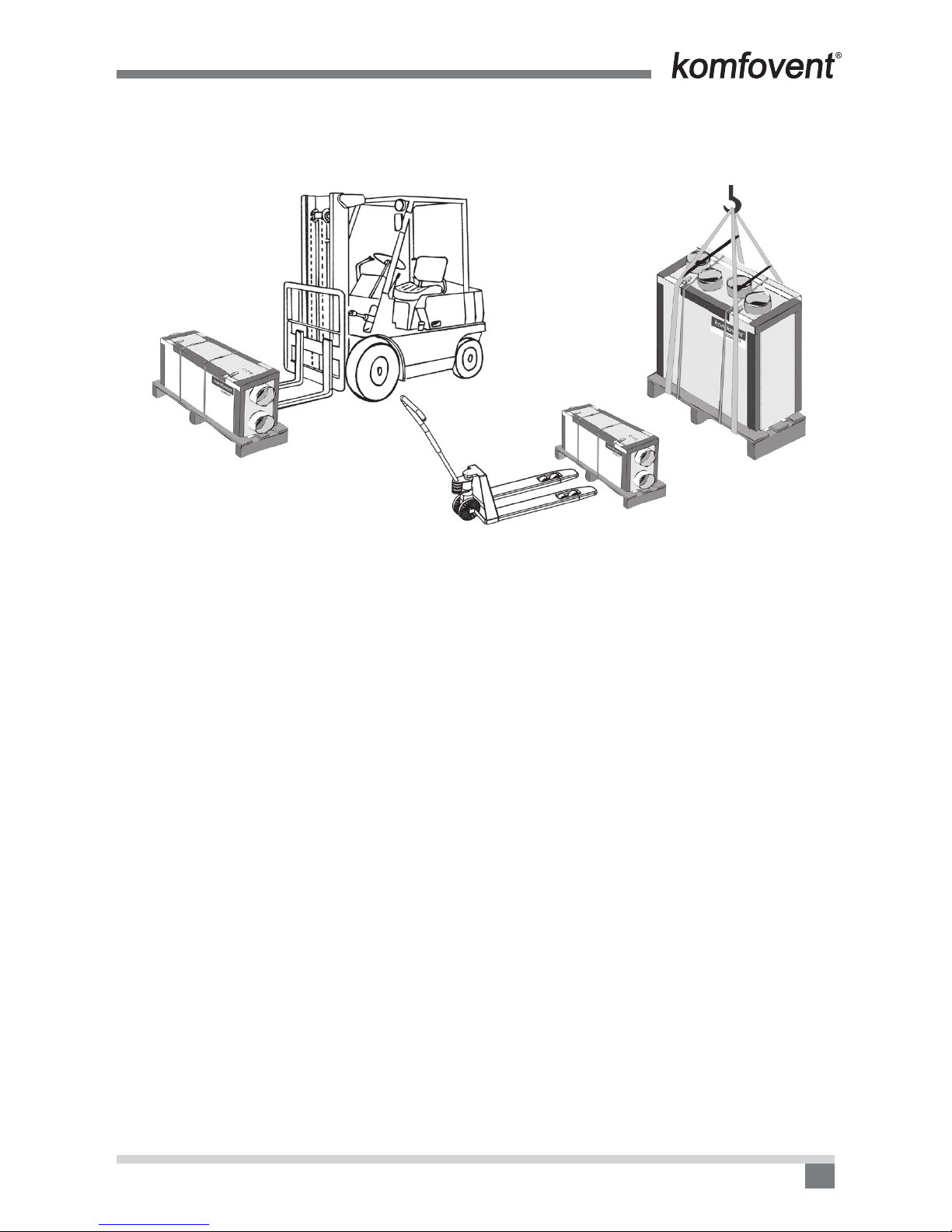

During air handling unit operation the process of condensation could be caused because of cold outdoor air

or due to high ambient air humidity (3 picture).

Indoor humidity

35

30

25

20

15

10

Indoor temperature, °C

10% 20% 30% 40% 50%

60%

70%

80%

90%

100%

Outside temperature, °C

-25 -20 -15 -10 -5 0510

3 picture. Condensation on unit surface diagram

UAB AMALVA we reserve the right to make changes without prior notice 7

D2-18-01

Suppose that supply air temperature is -25°C. Ambient air temperature, where air handling unit is installed,

is +20°C. In this case, condensate may appear on the outer surfaces of the air handling unit when relative hu-

midity in room is in range from 23% up to 100% (from point where curves of outside and inside air temperatures

crosses till the maximum value).

In other case, suppose that supply air temperature is 0°C. Indoor air temperature where air handling unit

is installed is +20°C. In this case, condensate may appear on the outer surfaces of the air handling unit when

relative humidity in room is in range from 43% up to 100% (from point where curves of outside and inside air

temperatures crosses till the maximum value).

To avoid condensation on unit outer surface use following solutions:

1) There should be maintained a lower relative humidity in the room where air handling unit is installed;

2) Preheater should be installed to increase the supply air temperature

EN

UAB AMALVA we reserve the right to make changes without prior notice

8

D2-18-01

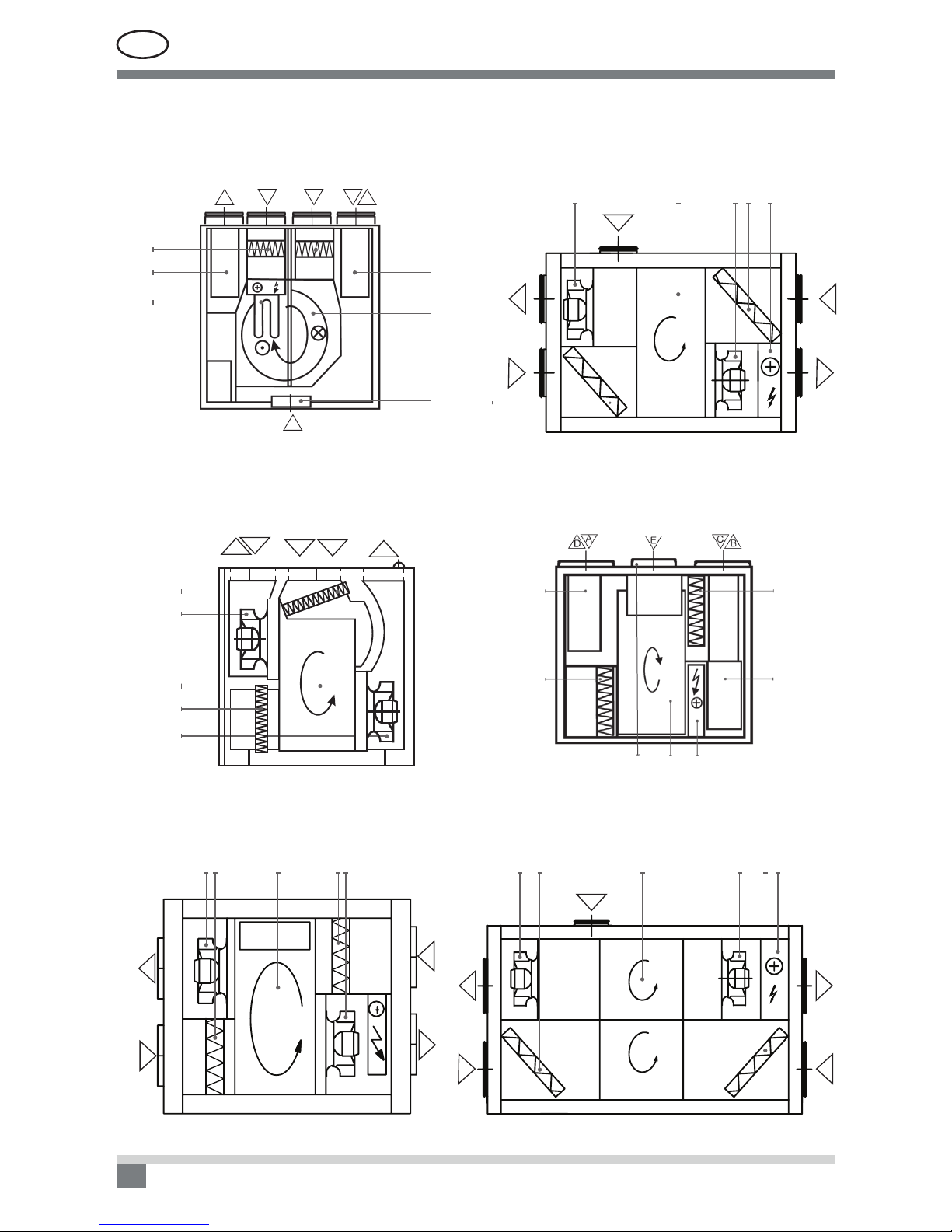

Air Handling Units Schemes

6

3

4

5

712

DOMEKT R 400 V / DOMEKT R 450 V

5

2

7

4

3

6

1

BA C E D

E

DOMEKT R 200 V

6

3

1

5

4

C

BA E D

DOMEKT R 300 V

D

A

C

B

341 5

6

DOMEKT R 400 H

E

D

A

C

B

3

4

156 2

DOMEKT R 250 F C6

C

B

A

D

E

6 3 1 5 4 2

DOMEKT R 400 F

UAB AMALVA we reserve the right to make changes without prior notice 9

D2-18-01

E

D

A

C

B

6 3 1 54 2

DOMEKT R 700 H

A

D

E

C

B

63 1 4 5 2

DOMEKT R 500 H C6

D

A

E

C

B

63 1 45 2

DOMEKT R 600 H

B

E

ADC

2

5

4

3

6

1

DOMEKT R 500 V** / DOMEKT R 700 V**

C

BD

A

2 6 13 54

DOMEKT R 700 F

EN

UAB AMALVA we reserve the right to make changes without prior notice

10

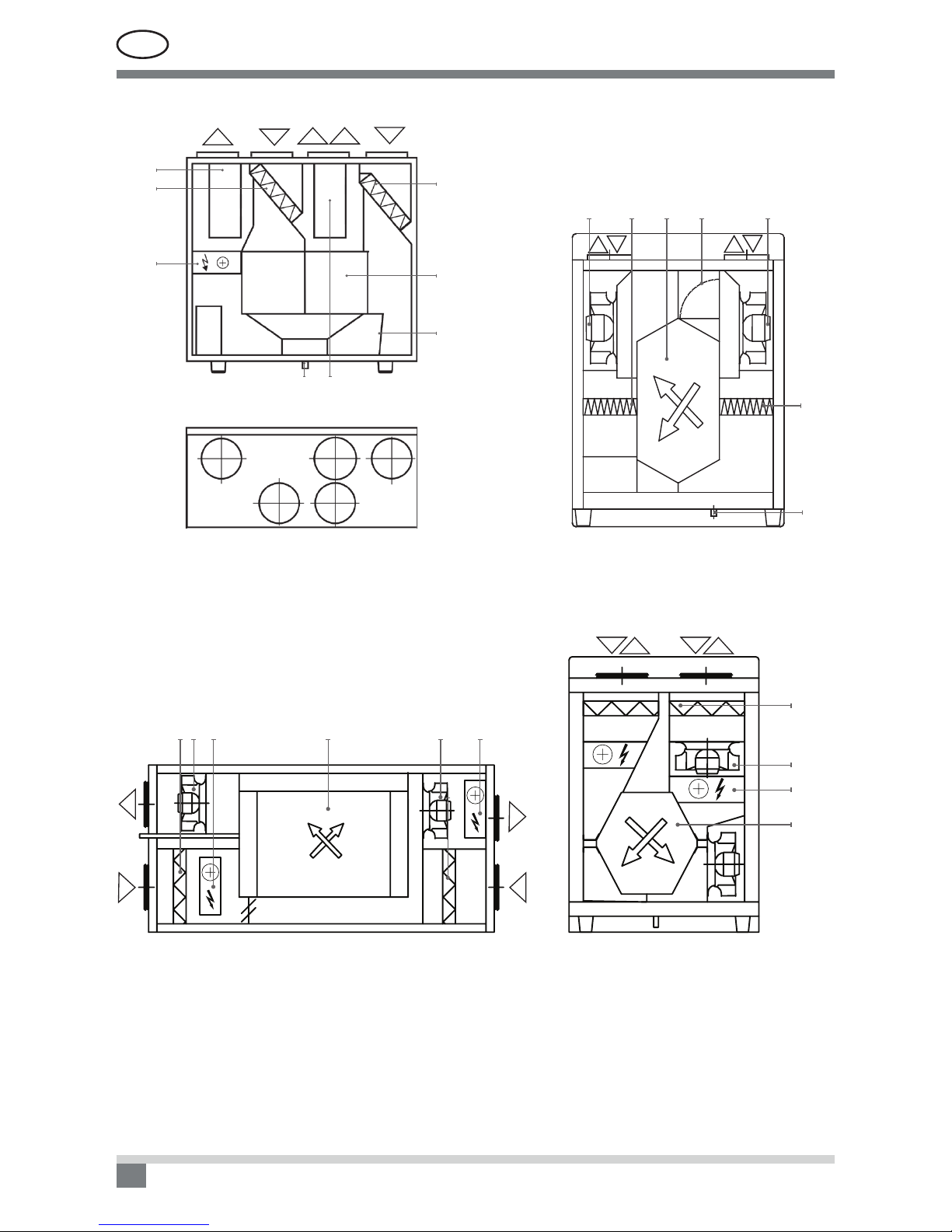

D2-18-01

ADCB

3

6

2

1

DOMEKT CF 400 V

CD

43

1

5

68

BEA

2

7

BCEDA

DOMEKT PP 300 V / 450 V

6 3 1 7 5

4

8

DABC

DOMEKT CF 250 V

D

A

B

C

1263 5

4

2

DOMEKT CF 250 F

UAB AMALVA we reserve the right to make changes without prior notice 11

D2-18-01

A

D

C

B

1

263 5 24

DOMEKT CF 500 F

B

C

D

A

1

263 5 24

DOMEKT CF 700 F

A

D

C

B

1

263 5 24

DOMEKT CF 700 H

+

+

DACB

623 4 5 2

DOMEKT CF 700 V

4 6 3

DOMEKT S 650 F / 800 F

A. Outdoor intake

B. Supply air

C. Extract indoor

D. Exhaust air

EE. Kitchen hood connection

(by-pass – extraction without heat recovery)

1. Rotary or plate heat exchanger

2. Electric or water air heater

3. Supply air lter

4. Exhaust air lter

5. Supply fan

6. Exhaust fan

7. Air by-pass damper

8. Condensate drain (the water trap must be installed)

EN

UAB AMALVA we reserve the right to make changes without prior notice

12

D2-18-01

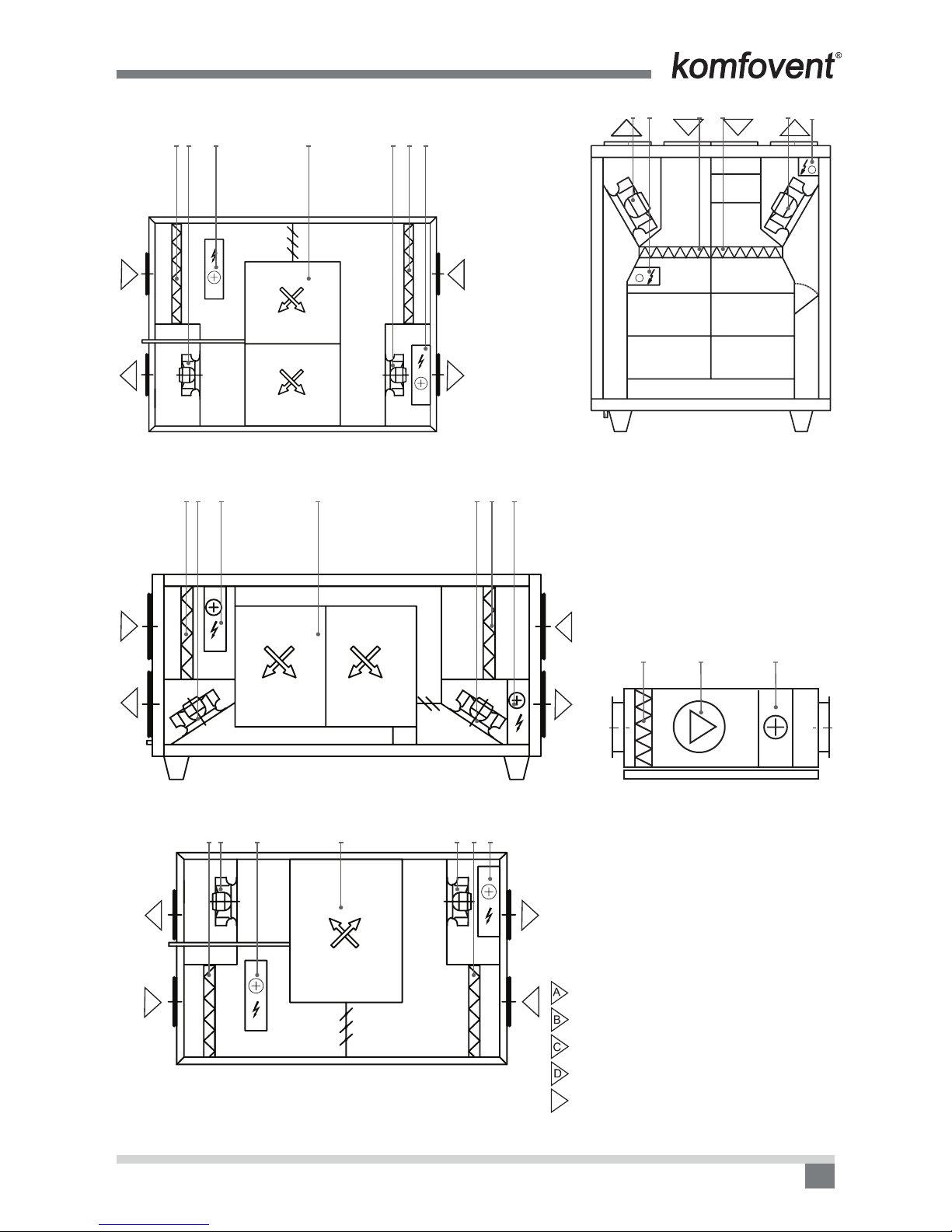

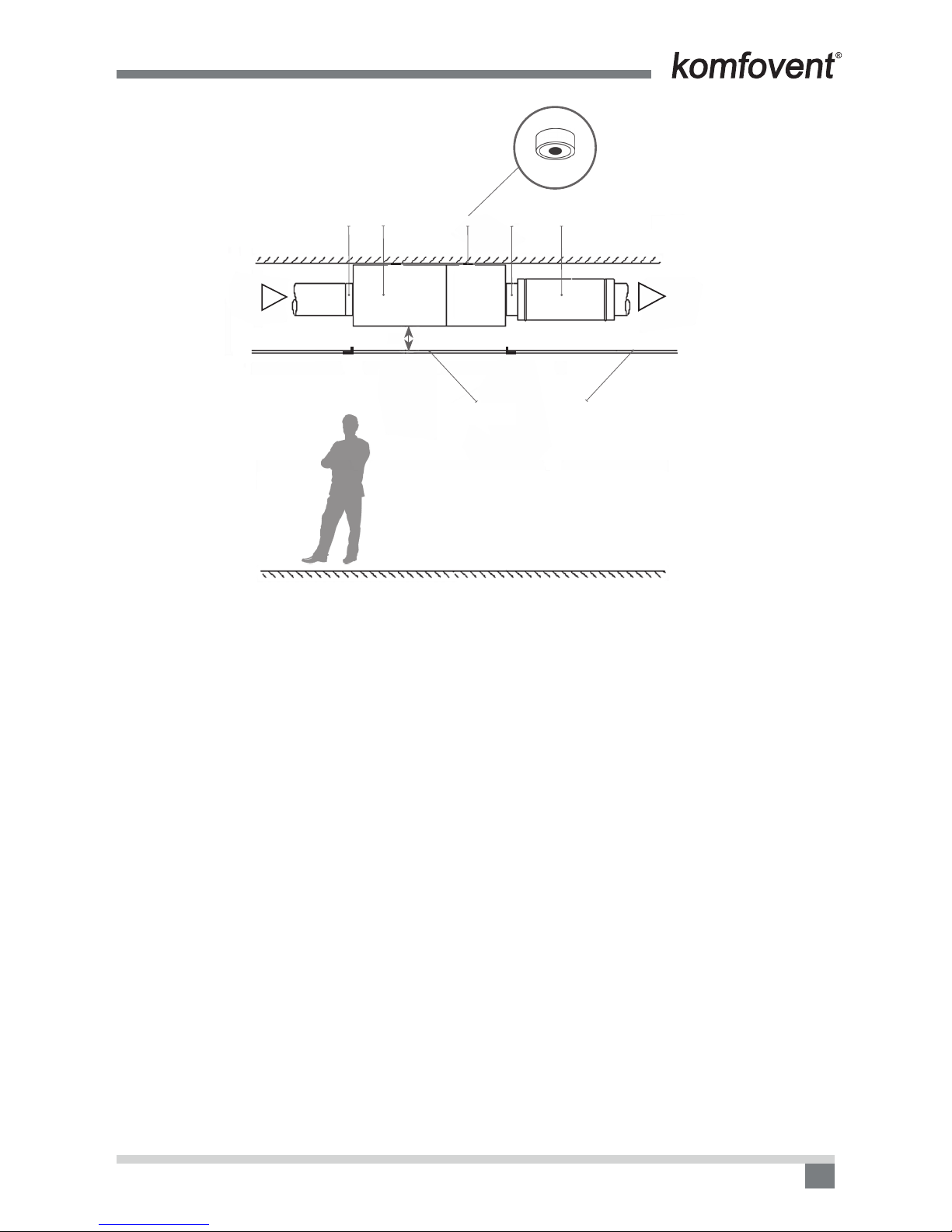

4. INSTALLATION

It is recommended to install the air handling unit in a separate room or in the attic on a hard smooth surface

insulated with a rubber mat. The minimum free space in front of the control panel should be not less than

700 mm. The free space over the top of the unit should be at least 300 mm (4 a, b Picture). Rubber vibration

absorbers must be used when unit is going to be mounted on the wall or ceiling.

The place for the unit must be selected with allowance for minimum access to the unit for maintenance or

service and must comply with safety requirements. Opening for inspection can not be smaller than dimensions

of the unit and unit itself must be mounted in a way, that if needed (for example in case of complicated repair)

it can be easily dismounted.

Minimum Maintenance Space for Horizontal Units

100 mm

min. 700 mm

4 a Picture

Minimum Maintenance Space for Vertical Units

100 mm

min. 700 mm

4 b Picture

Unit Installation Scheme

23

12

4 5

2

1

3

4

1. Air handling unit

2. Air duct connections

3. Sound attenuator

4. Drain siphon (if provided)

5. Rubber vibration absorber (not included in unit set)

4 Picture

UAB AMALVA we reserve the right to make changes without prior notice 13

D2-18-01

B

ceiling

A

min. 100 mm

5

B

1

Inspection

trapdoor

223

5 Picture

EN

UAB AMALVA we reserve the right to make changes without prior notice

14

D2-18-01

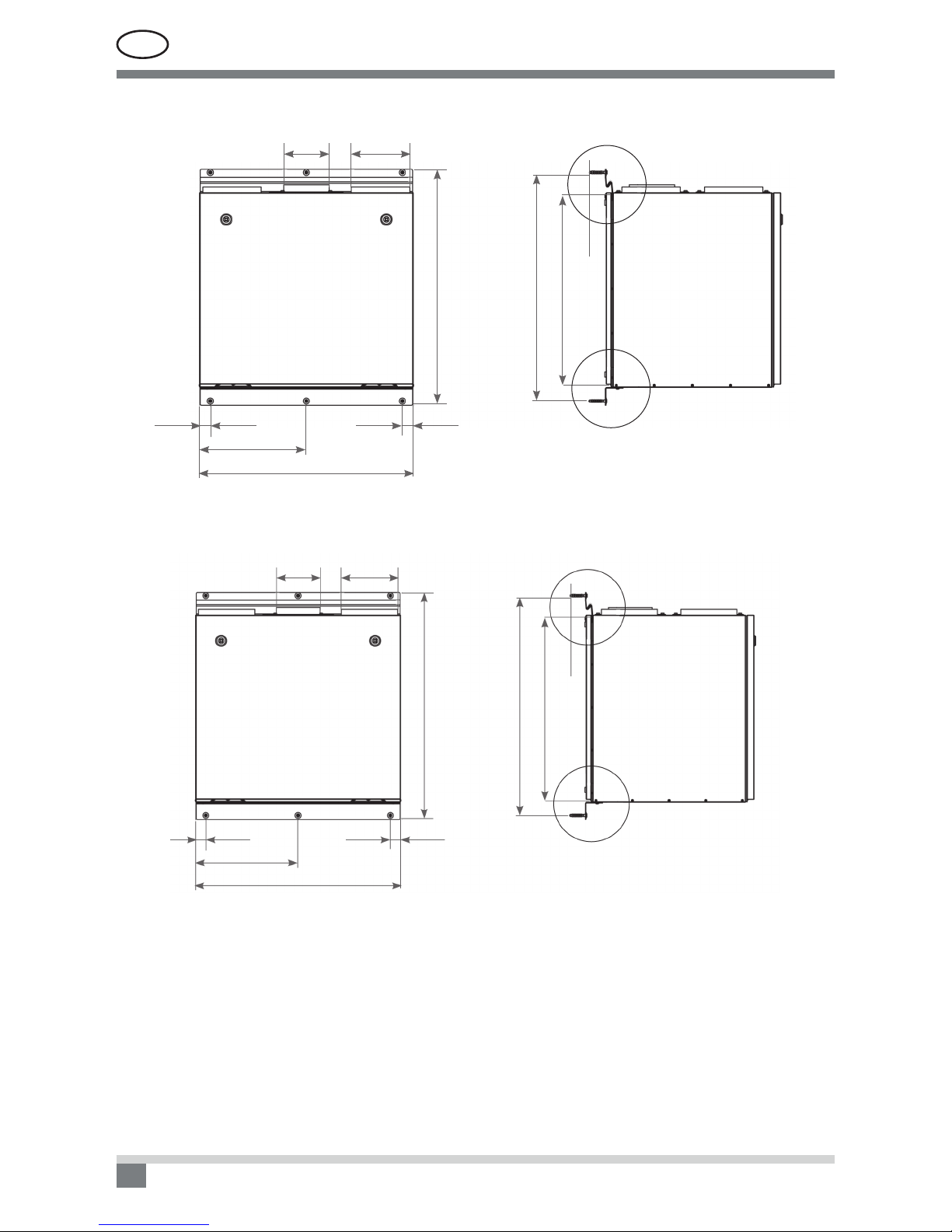

DOMEKT R 400 V Unit brackets’ positions

B

A

641

604

57

662

30

300

600

30

Ø125 Ø160

6 Picture

DOMEKT R 450 V Unit brackets’ positions

Ø125 Ø160

A

57

667

704

B

30

340

30

680

7 Picture

UAB AMALVA we reserve the right to make changes without prior notice 15

D2-18-01

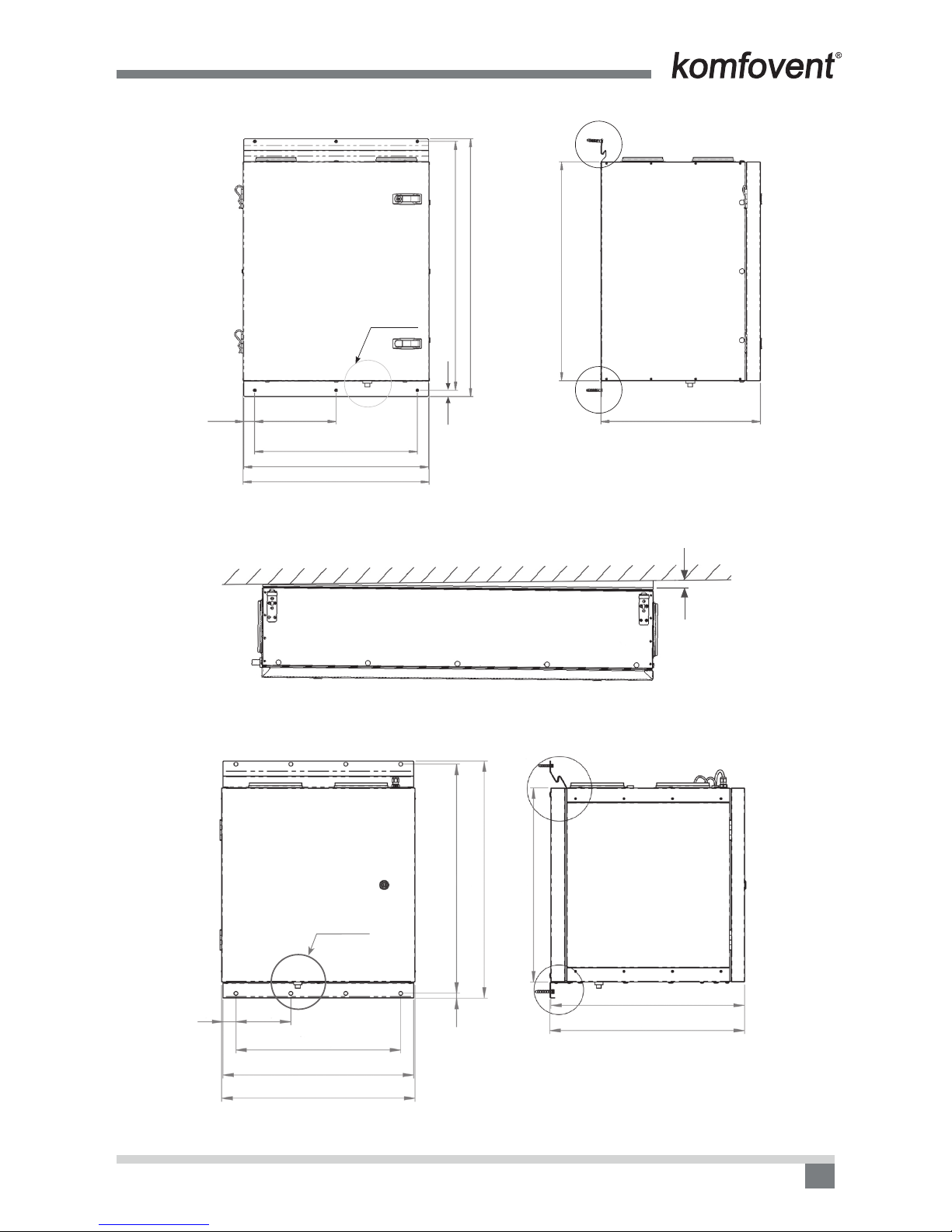

Įrenginio DOMEKT CF 250 V Unit brackets’ positions

view 1

35 260

520

590

595

20

B

A

510

700

824

795

8 Picture

DOMEKT CF 250 F Unit brackets’ positions

15

9 Picture

DOMEKT CF 400 V Unit brackets’ positions

view 1

40 170

3 × 170 = 510

590

598

15 709

734

600

600

603

A

B

10 Picture

EN

UAB AMALVA we reserve the right to make changes without prior notice

16

D2-18-01

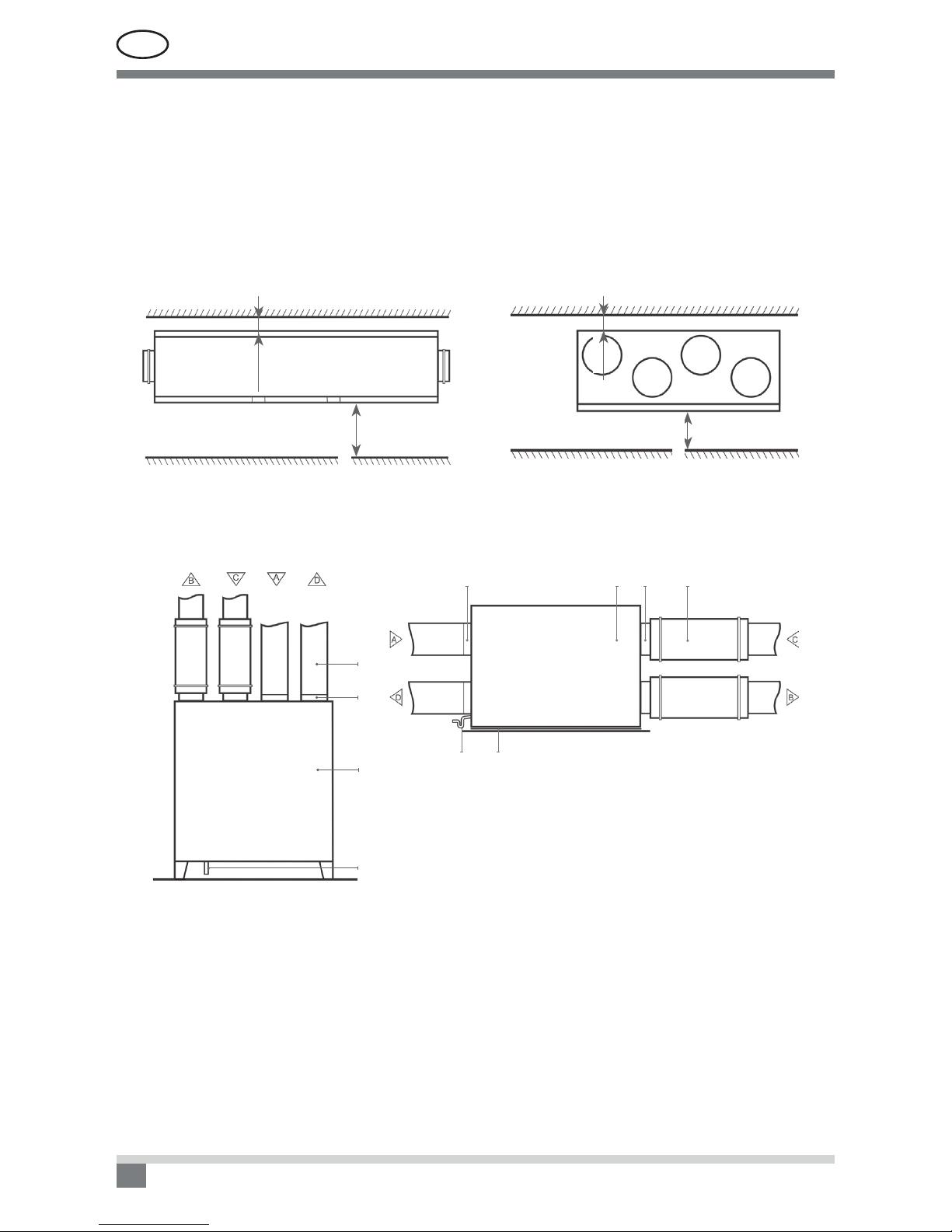

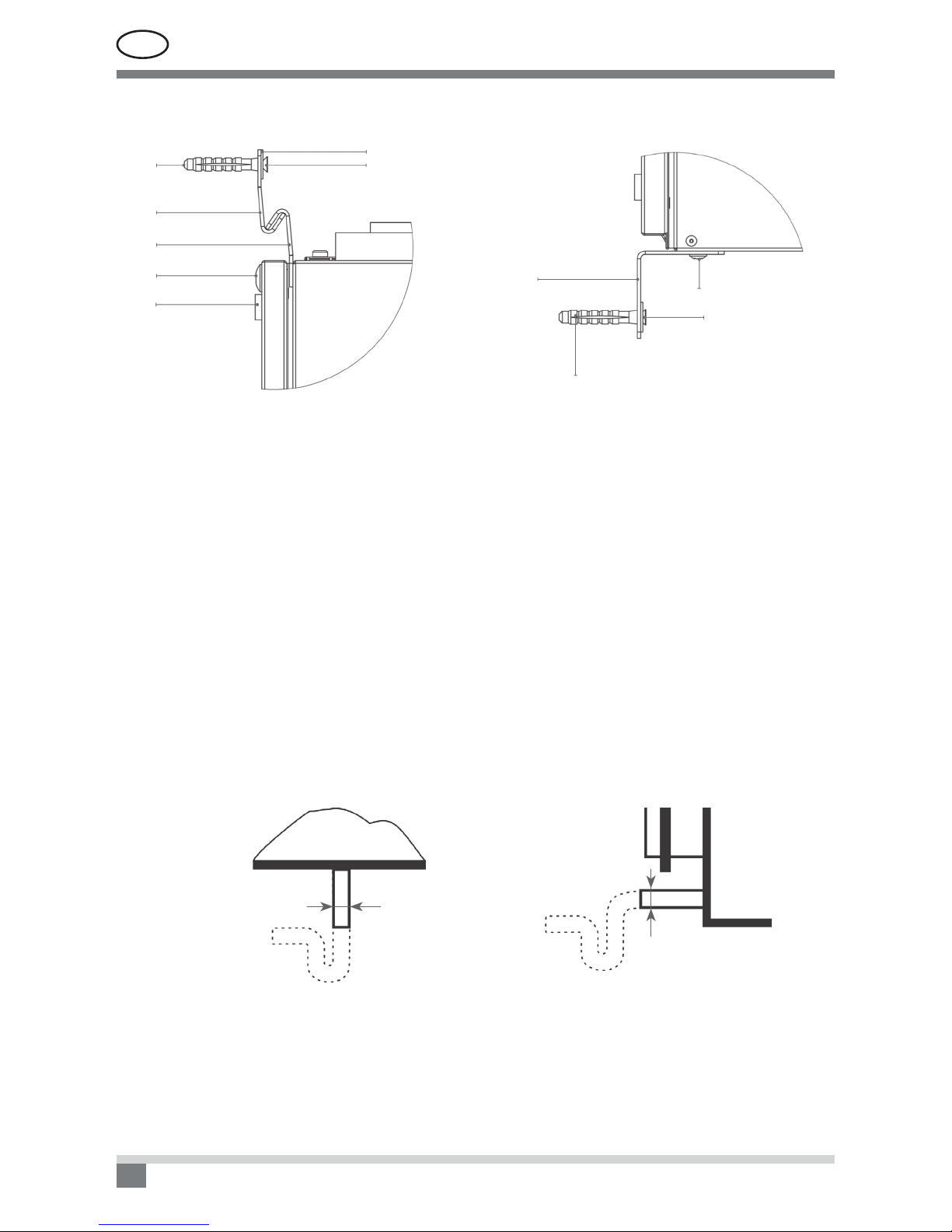

4.1. Condensate Drain Connections

All condensate drain connections must be correctly trapped. Incorrect trapping can result in ooding within the

unit and consequent ooding of the immediate area. Fill the drain trap with water before starting up the unit.

All drain lines should be insulated where passing through any space where damage from condensation

drip might occur. If the unit is installed in unheated premises the condensate pipe should be heat-insulated and

heated with heating cable.

A condensate pipe and a drain trap

Drain scheme of Vertical Unit

view 1

D = 15

12 a Picture

Drain scheme of Horizontal Unit

view 2

D = 15

view 2

12 b Picture

The bend of the water trap can be repositioned by turning it to the right or the left. The drain line from the

water trap must be arranged so that it will not damage adjacent unit sections or building elements. If the drain

line is run through cold spaces, it should be insulated to prevent freezing. A heating cable may be required.

Pictures 11 a and 11 b show unit’s upper and bottom xing element.

2

3

4

5

6

9

1

8

2

7

1

11 a Picture 11 b Picture

1. Screw

2. Wall plug

3. Hanging bracket 1

4. Hanging bracket 2

5. Bolt M5

6. Gasket

7. Self tapping screw

8. L-shape bracket

9. Washer M5 DIN9021

UAB AMALVA we reserve the right to make changes without prior notice 17

D2-18-01

4.1.1. Water trap installation for a unit section mounted on the suction side

Since the fans in most air handling units are last in the chain of functions and generate sub-atmospheric pres-

sure inside the unit,it is very important to correctly install the water trap. Because of that reason condensate

can be hardly eliminated from the air handling unit and the technical premise may get covered with condensate.

Height H1must be at least equivalent in mm to half of the negative pressure inside the unit in mm water gauge.

Height H2must be at least equivalent in mm to the negative pressure inside the unit in mm water gauge.

Ø 32

25-240106

DN 40

95

H1, H2

140-310

Condensate Condensate

H2

H1

Precaution: The drainage siphon should be mounted on the outlet t-

ting pipe of every drip tray for complete condensate drainage from the air

handling unit and prevention of penetration of offensive odours from an

efuent into the ventilation system.

In case of the outdoor operation of the air handling unit, the siphon and

the bleeders should be heated with an electric thermal cable (if ambient

air temperature tamb < 0 °C). The siphon and the bleeders should be heat-

insulated with an insulating material.

4.1.2. Water trap installation for a unit section mounted on the pressure side

Since the fans in most air handling units are not last in the chain of functions and generate over-atmospheric

pressure inside the cooling section. In such case the consisted condensate can be easily removed from AHU

and there will be no strict requirements for siphon‘s installation. A drainage siphon is enough with a minimum

rake.

RECOMMENDATION: The drainage siphon must be installed in connection with not less size pipe diameter.

Any drainage systems must not be connected directly to the municipal sewage system. The condensate tray

shall be easily accessible for cleaning and disinfection.

EN

UAB AMALVA we reserve the right to make changes without prior notice

18

D2-18-01

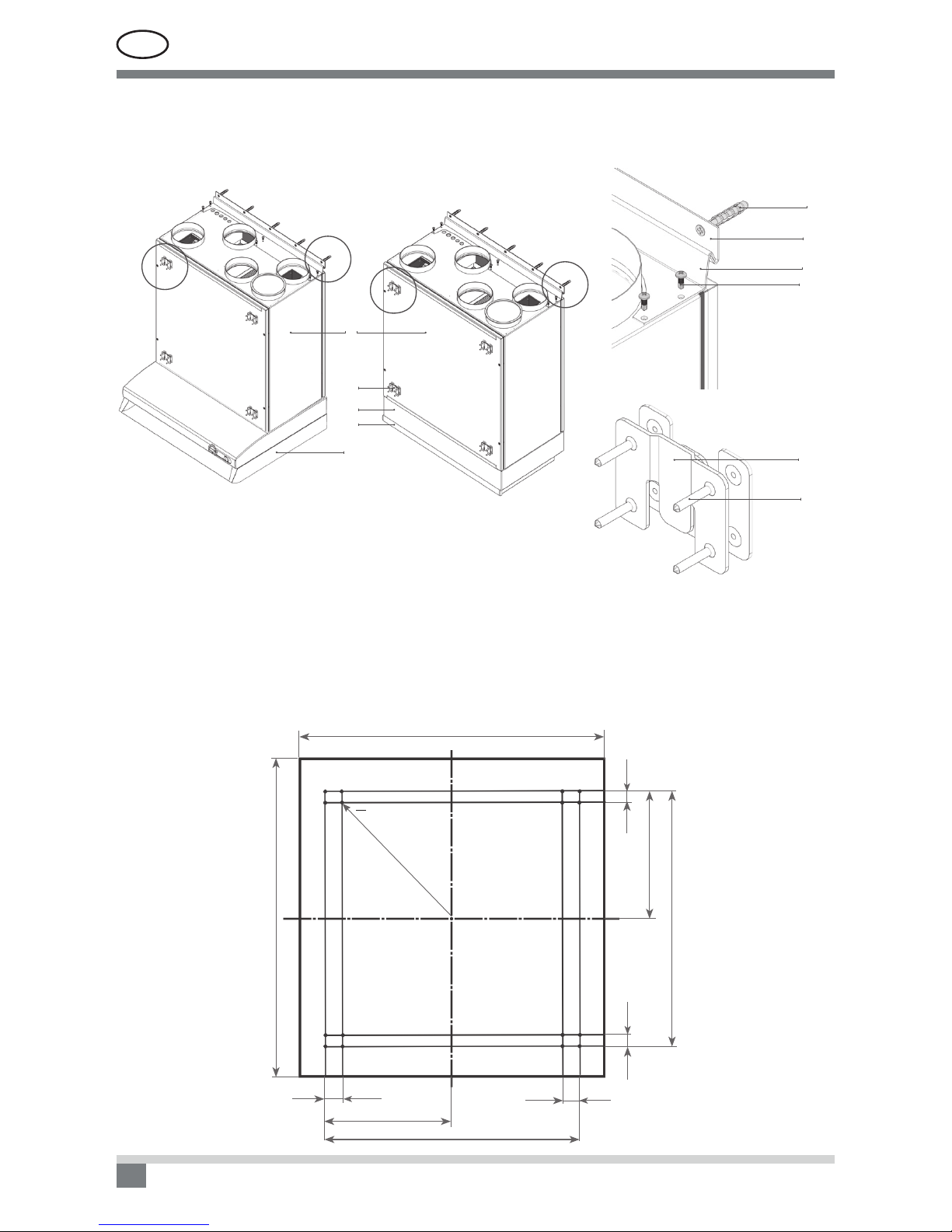

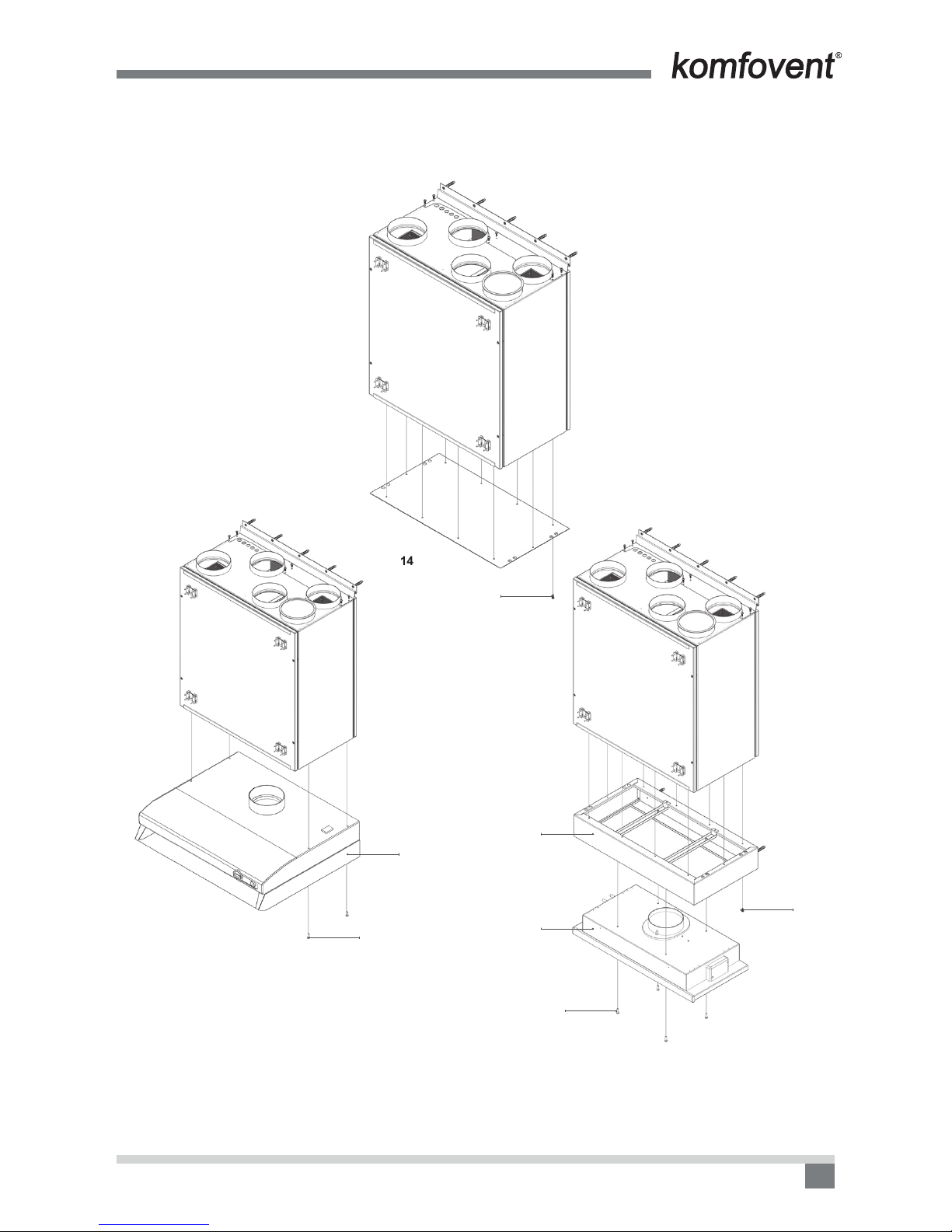

DOMEKT R 200V unit with kitchen hood

Air handling unit DOMEKT R 200 V can be mounted with one of the two types of kitchen hoods (13, 14 Picture).

1. Air handling unit DOMEKT R 200V

2. Kitchen hood adapter 392-12

3. Kitchen hood 392-12

4. Standard kitchen hood

5. Wall plug 8×50 + screw 4,5×50

6. Wall mounting bracket

7. Unit bracket

8. Self tapping screw 4,2×13

9. Bracket for decorative panel

10. Screw 2.5×16 with cone head

Dimensions for mounting furniture panel

22

625

600

500

250

22

32.5

500

250

32.5

Ø 2(depth – 5 mm) 16 holes

13 Picture

1

9

2

3

4

A

B

BA

A

B

5

6

7

8

9

10

UAB AMALVA we reserve the right to make changes without prior notice 19

D2-18-01

14a Picture

5 (×10)

Instalation scheme of DOMEKT R 200V unit with kitchen hood

Before installing kitchen hood, bottom cover plate must be removed by remooving xing screws (14a pic.)

14b Picture. Installation of standard kitchen hood 14c Picture. Installation of kitchen hood 392-12

1. Kitchen hood adapter 392-12

2. Standard kitchen hood

3. Kitchen hood 392-12

4. Screws M4 for hood xation (4 picture)

5. Self tapping screws 4,2×13 for adapter xation (10 picture)

5 (×10)

4 (×4)

4 (×4)

3

2

1

EN

UAB AMALVA we reserve the right to make changes without prior notice

20

D2-18-01

Dimensions for the DOMEKT R 200 V installation space

804

42

320

625

~777

500

140

140 × 4 = 560

575

600

15 Picture. Dimensions with standard kitchen hood

16 Picture. Dimensions with kitchem hood 392-12

320

42

738

94

625

140×4 = 560

140

25

600

This manual suits for next models

12

Table of contents

Popular Ventilation manuals by other brands

nilan

nilan Compact P installation instructions

Genvex

Genvex GES Energy S installation manual

DVS

DVS Positive Pressure Home Ventilation System operating guide

Fantech

Fantech 405335 installation manual

Monodraught

Monodraught Cool-phase Nova operating & maintenance manual

GE

GE UVB30 Owner's Manual & Installation Instructions