KONE ReSolve 200

Installation Instruction

6 (258) AM-10.65.001

(D) 2013-04-17

© 2009 KONE Corporation

All rights reserved.

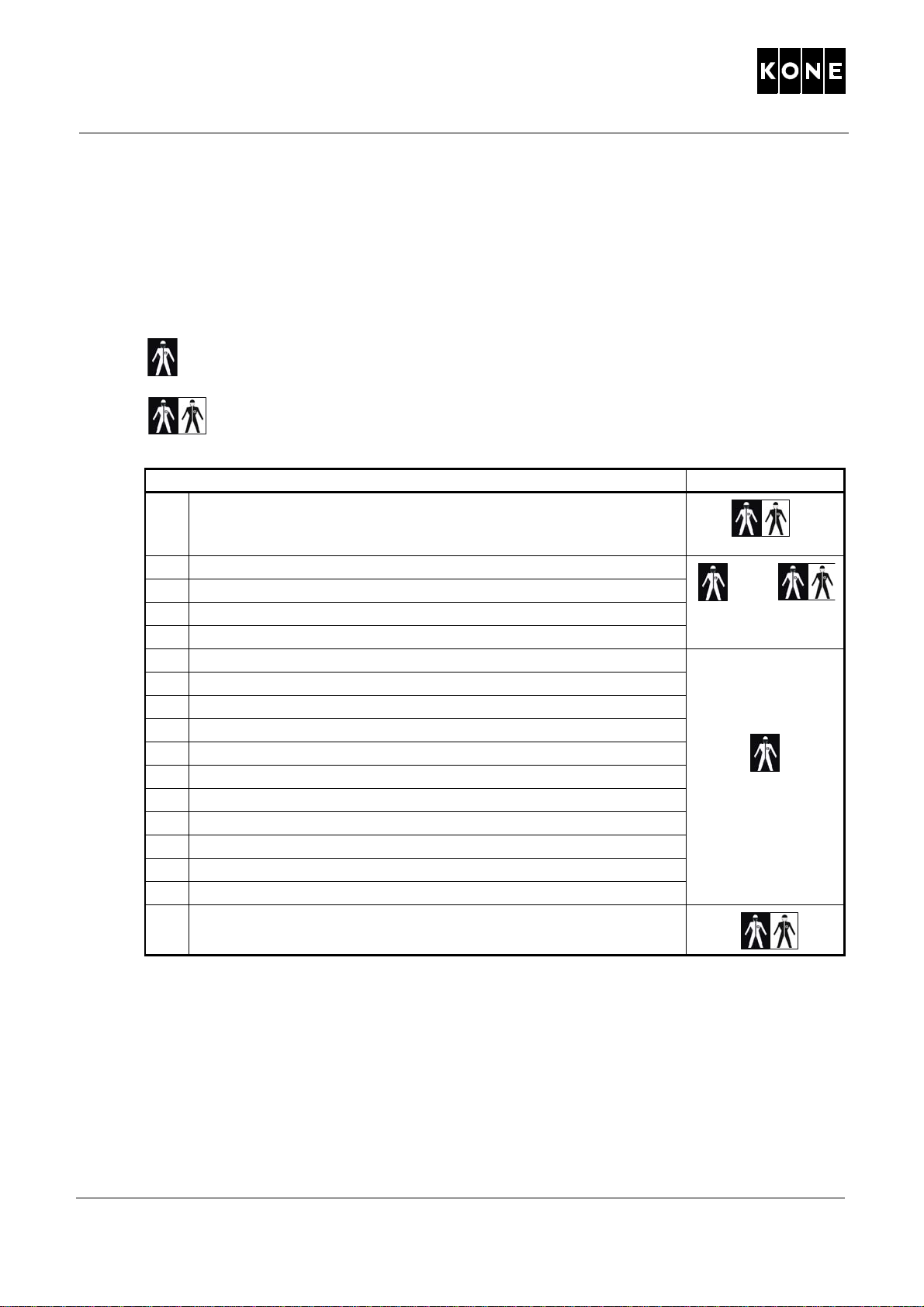

14.18 Wiring of close command door operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

14.19 Wiring of FIAM B/S door operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

14.20 Wiring of Sabiem C door operator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

14.21 Wiring of ACC 230V door operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

14.22 Wiring of general 24V electronic control door operator. . . . . . . . . . . . . . . . . . . . . . 197

14.23 Wiring of Selcom 1PH 220V automatic door operator. . . . . . . . . . . . . . . . . . . . . . . 199

14.24 Wiring of no car door, EMO N, AT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

14.25 Wiring of BOF unit for non-automatic doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

14.26 Wiring of new COP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

14.27 Wiring of old COP and display (if any, parallel I/O module). . . . . . . . . . . . . . . . . . . 204

14.28 Connection of ACU, if applicable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

14.29 Connection of KRM, KSS ReVive signalization. . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

14.30 Connection of KRM, parallel signalization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

14.31 Wiring of car extension door (CED). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

15 FULL SPEED ADJUSTMENT / COMMISSIONING / SAFETY INSPECTIONS . . . . . . . . 210

15.1 Balancing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

15.2 Selecting roll call type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

15.3 Selecting LWD type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

15.4 Shaft setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

15.5 Connecting FRD / FID (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

15.6 Adjusting motor no load current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

15.7 Checking creeping time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

15.8 Motor slip compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

15.9 Floor level adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

15.10 Final steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

15.11 External options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

15.12 Commissioning of the car door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

15.13 Check the parameters for door inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

15.14 Checking KCE board versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

15.15 Testing landing door locks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

15.16 Testing safety contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

15.17 Measuring insulation resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

15.18 Measuring earth continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

15.19 24 VDC ground fault test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

15.20 Testing operation of RCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

15.21 Speed measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

15.22 Current measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

15.23 Testing the final limit switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

15.24 Drive time supervision (DTS) test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

15.25 Buffer tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

15.26 Overspeed governor test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

15.27 Safety gear test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237