Instruction manual SMV 10 600B – 60 1500B Publ. no. 6196.082 1117, Version 02 3

Table of contents

TABLE OF CONTENTS

YOUR MACHINE FROM KONECRANES

LIFTTRUCKS ................................................................. 2

Technical remark .............................................................. 2

Delivery inspection ........................................................... 2

TABLE OF CONTENTS ................................................ 3

SAFETY REGULATIONS .............................................. 4

Safety rules ....................................................................... 4

Warning texts and important information ........................ 5

Before driving ................................................................... 6

Preventions of accidents .................................................... 6

Norms .............................................................................. 6

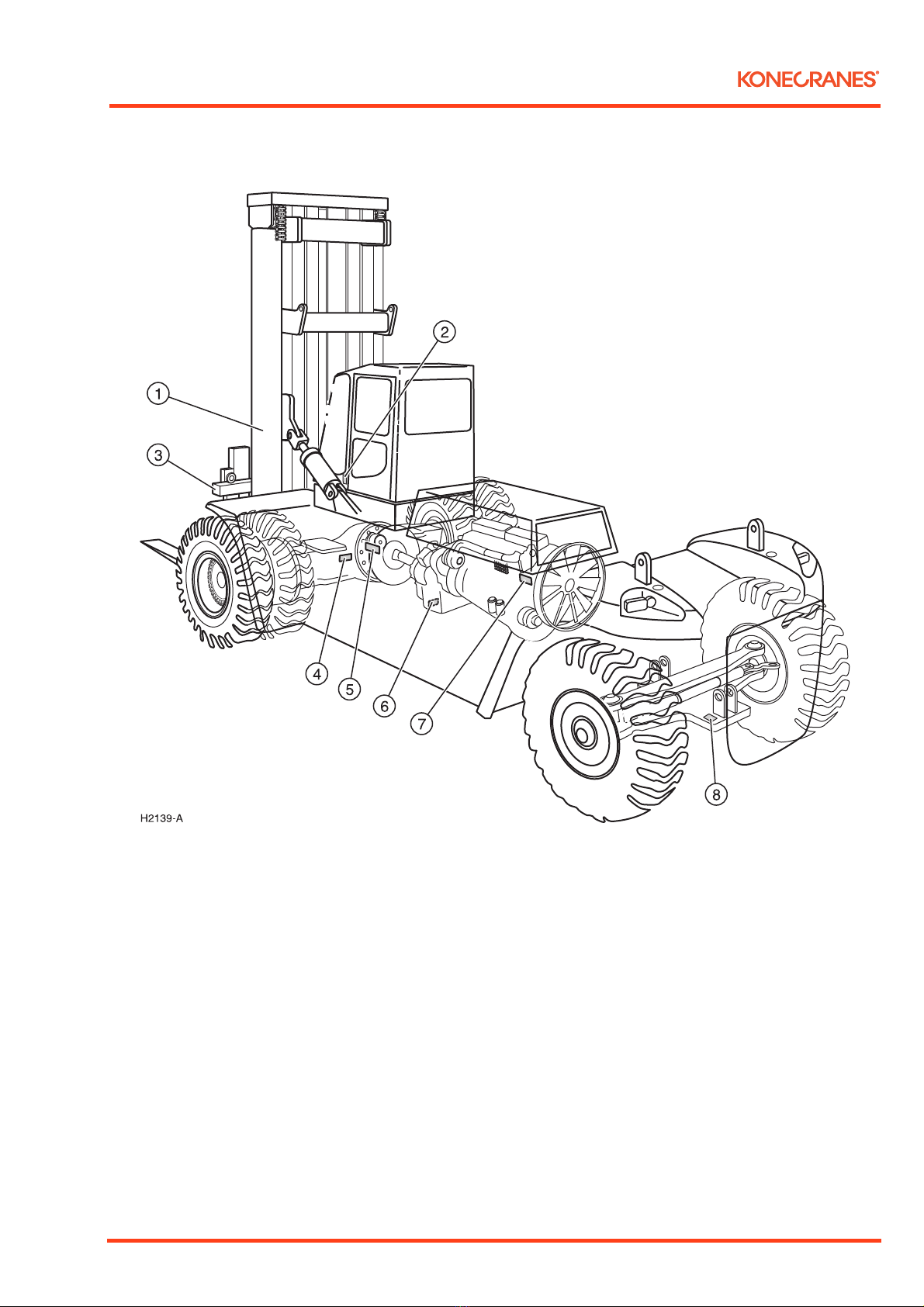

PRESENTATION OF THE MACHINE ........................ 7

Technical description ........................................................ 7

Overview of the machine .................................................. 8

ID-plates and serial number .............................................. 9

Cabin controls and indicators ......................................... 10

Warning indicators and gauges ....................................... 11

Description of Drive monitor IQAN MD3 .................... 12

Driver seat ...................................................................... 17

Steering .......................................................................... 18

Declutch function ........................................................... 18

Parking brake switch ....................................................... 18

Emergency stop .............................................................. 19

Ventilation ..................................................................... 20

Cabin tilting ................................................................... 21

Locking of doors ............................................................. 21

Electrical system ............................................................. 22

DRIVING AND MANOEUVRING OF LOAD .......... 26

Start the engine ............................................................... 26

Stop the engine ............................................................... 27

Driving ........................................................................... 28

Manoeuvring of load ...................................................... 31

Manoeuvring of mast ...................................................... 32

LIFTING AND TRANSPORTING THE MACHINE .... 37

Towing ........................................................................... 37

Lifting the machine ....................................................... 38

Transport ....................................................................... 40

SERVICE AND MAINTENANCE ............................... 41

General ........................................................................... 41

Daily inspection and service prior to start ....................... 43

Cleaning ......................................................................... 49

Pressure draining of the hydraulic system ........................ 50

Wheel replacement ......................................................... 50

Retightening of bolt joints, torque .................................. 57

Overview lubrication schedule ........................................ 62

Engine, oil, oil filter and oil cleaner, Scania .................... 64

Fuel system, Scania ......................................................... 66

Engine, oil, and oil filter, Volvo ...................................... 68

Fuel system, Volvo .......................................................... 70

Air intake system ............................................................ 72

Transmission DANA, oil, oil filter and breathing valve ... 74

Transmission ZF, oil, oil filter and breathing valve ......... 76

Driving shaft, inspection and replacement of oil ............ 78

Hydraulic system ........................................................... 80

Lubrication .................................................................... 82

Inspection of the cooling system .................................... 85

Drive belt ....................................................................... 86

Engine ........................................................................... 86

Inspection of the battery ................................................ 87

Control steering axle bearing .......................................... 88

Wheel bearings .............................................................. 88

Spindle bearing .............................................................. 89

Inspection of the exhaust system for leaks ...................... 90

Fuel tank ........................................................................ 90

Wiper blade replacement ............................................... 91

Weld construction ......................................................... 91

Mast and fork carriage ................................................... 92

Parking brake ................................................................. 94

INSPECTION AND MAINTENANCE SCHEDULE .... 96

Delivery inspection and start-up .................................... 96

Service items .................................................................. 96

Daily inspection and service prior to start ...................... 97

Service items for the first 150 hours ............................... 97

Inspection and maintenance schedule ............................ 98

Service schedule engines ................................................. 99

Liquid volumes ............................................................ 100

FUEL AND OIL RECOMMENDATIONS ............... 101

The quality of the engine oil ........................................ 101

Extended oil replacement intervals ............................... 101

Recommended fuels and hydraulic oils ........................ 102

Instruction manual SMV 10 600B – 60 1500B Publ. no. 6196.082 1117, Version 02