Cascade D Series Manual

Other Cascade Forklift manuals

Cascade

Cascade G Series User manual

Cascade

Cascade C Series User manual

Cascade

Cascade KOOI ROLLERFORKS User manual

Cascade

Cascade F Series User manual

Cascade

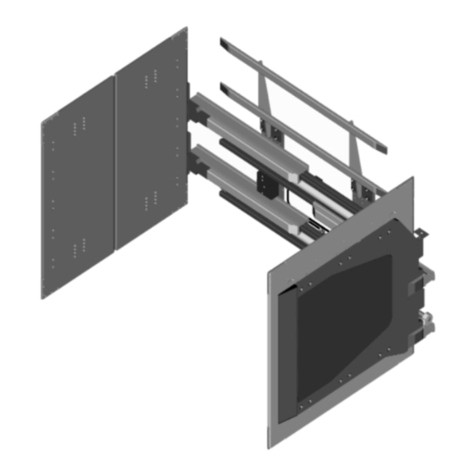

Cascade K Series User manual

Cascade

Cascade C Series User manual

Cascade

Cascade Turnafork E Series User manual

Cascade

Cascade iForks User manual

Cascade

Cascade Viewmast II 30C Triple User manual

Cascade

Cascade E Series User manual

Cascade

Cascade E Series Manual

Cascade

Cascade KOOI Reachforks 20B TFT User manual

Cascade

Cascade K Series User manual

Cascade

Cascade J Series User manual

Cascade

Cascade N Series User manual

Cascade

Cascade F Series User manual

Cascade

Cascade H Series User manual

Cascade

Cascade G Series Manual

Cascade

Cascade J Series User manual

Cascade

Cascade 80R User manual