Kongsberg Simrad HLD350 MK2 User manual

INSTRUCTION MANUA

L

Simrad HLD350 MK2

Simrad HLD2000 MK2L

Hydraulic Linear Drive

Note!

Simrad AS makes every effort to ensure that the information contained within this

document is correct. However, our equipment is continuously being improved and

updated, so we cannot assume liability for any errors which may occur.

Warning!

The equipment to which this manual applies must only be used for the purpose for which

it was designed. Improper use or maintenance may cause damage to the equipment or

injury to personnel. The user must be familiar with the contents of the appropriate

manuals before attempting to operate or work on the equipment.

Simrad AS disclaims any responsibility for damage or injury caused by improper

installation, use or maintenance of the equipment.

Copyright

© 2005 Simrad AS

The information contained within this document remains the sole property of Simrad AS.

No part of this document may be copied or reproduced in any form or by any means, and

the information contained within is not to be communicated to a third party, without the

prior written consent of Simrad AS.

www.simrad.com

Instruction manual

20220109E 1

Instruction Manual

This manual is intended as a reference guide for correctly installing

and maintaining the HLD350 MK2 and HLD2000 MK2 Hydraulic

Linear Drives.

Please take time to read this manual to get a thorough understanding of

the drive system components and its relationship to a complete autopilot

system.

Other documentation material that is provided with your system

includes a warranty card. This must be filled out by the authorized

dealer that performed the installation and mailed in to activate the

warranty.

Instruksjonsmanual

Denne manualen gir veiledning om installasjon og vedlikehold av de

hydrauliske drivenhetene HLD350 MK2 og HLD2000 MK2.

For å få en forståelse av drivenhetens virkemåte og funksjon i et

autopilotsystem bør manualen leses grundig.

Sammen med ditt system følger et garantikort. Dette må fylles ut av

installatør og sendes inn for at garantien skal være gyldig.

Simrad Hydraulic Linear Drive

2 20220109E

Document revisions

Documentation

department

Hardware/Software

design

Project/Product

Management

Rev Date Sign Date Sign Date Sign

– 07.97 N.G. 07.97 I.K. 07.97 Th.H.

A 29.04.98 N.G. 29.04.98 I.K. 29.04.98 Th.H.

B 21.09.99 N.G. 21.09.99 I.K. 21.09.99 Th.H.

C 15.11.00 N.G. 16.11.00 I.K. 16.11.00 Th.H.

D 19.02.03 N.G. 19.02.03 I.K. 19.02.03 Th.H.

E 16.02.05 16.02.05

Document history

Rev. – First edition

Rev. A New edition including MK2 versions

Rev. B Added measurement on figure 1. Adjusted figure 5.

Rev. C New environmentally friendly synthetic hydraulic oil, page 5, 6 and 7.

Corrected quantity for Pos.8 Bearing bush on fig. 11 from 1 to 2 and

description of P.N. 44165918 on page 23. Distributor list updated.

Rev. D New motors, type Lemac. Added colour on the o-ring at pos. 6, page 21

to avoid mix up. Minor corrections in text.

Rev. E Corrected part no. for RPU80 on page 19. Updated with new autopilot

computers.

Instruction manual

20220109E 3

Contents

1GENERAL..............................................................................................................5

2TECHNICAL SPECIFICATIONS.......................................................................7

2.1 Standard version .............................................................................................7

2.2 Split version....................................................................................................8

2.3 Dual cylinder version......................................................................................9

2.4 Comparison chart for HLD MK2 versions ...................................................10

3INSTALLATION .................................................................................................11

3.1 Mechanical installation.................................................................................11

3.2 Electrical connection ....................................................................................12

AC10/AC20 Autopilot Computer, J300X/J3000X Junction Unit ................12

J101A Junction Unit .....................................................................................12

4CONSTRUCTION AND PRINCIPLE OF OPERATION...............................15

4.1 Tank ..............................................................................................................15

4.2 Reversible Hydraulic Pump..........................................................................16

4.3 Hydraulic Rudder Cylinder ..........................................................................16

5PARTS LIST.........................................................................................................19

5.1 Linear drive units and main parts .................................................................19

5.2 Tank assembly ..............................................................................................20

5.3 Pump assembly .............................................................................................21

5.4 Cylinder assembly ........................................................................................22

6APPENDIX ...........................................................................................................24

6.1 Calculation of the force against the rudder...................................................24

Simrad Hydraulic Linear Drive

4 20220109E

Innhold

1 GENERELT............................................................................................................6

2 TEKNISKE SPESIFIKASJONER.......................................................................7

2.1 Delt versjon.....................................................................................................8

2.2 Dobbel sylinder versjon..................................................................................9

2.3 Sammenligningstabell for MK2 versjoner ...................................................10

3 INSTALLASJON .................................................................................................13

3.1 Mekanisk installasjon ...................................................................................13

3.2 Elektrisk tilkobling .......................................................................................14

AC10/AC20 autopilotcomputer/J300X/J3000X koblingsenhet ...................14

J101A koblingsenhet ....................................................................................14

4 KONSTRUKSJON OG VIRKEMÅTE .............................................................17

4.1 Tank ..............................................................................................................17

4.2 Reverserbar hydraulisk pumpe .....................................................................17

4.3 Hydraulisk rorsylinder..................................................................................18

5 PARTS LIST.........................................................................................................19

5.1 Linear drive units and main parts .................................................................19

5.2 Tank assembly ..............................................................................................20

5.3 Pump assembly .............................................................................................21

5.4 Cylinder assembly ........................................................................................22

6 TILLEGG .............................................................................................................26

Instruction manual

20220109E 5

1GENERAL

HLD350 MK2 and HLD2000 MK2 are hydraulic linear drives

designed for boats with mechanical steering systems such as wire and

cable steering (Edson, Whitlock, Teleflex).

The HLD is a compact, assembled unit, consisting of a reversible

hydraulic pump, a balanced hydraulic cylinder, by-pass valve and oil

tank.

Because of the direct connection to the rudder, the hydraulic linear

drive can be used even if the hand steering should fail. This can be an

important safety factor.

The by-pass valve makes it possible to use the helm with little back

drive force when the autopilot is switched off.

The HLD350 MK2 and HLD2000 MK2L supersede the previous

HLD350 and HLD2000L models. This manual also includes

HLD2000 MK2D. This model is based on the same main parts as

HLD350 MK2, but uses the HLD2000 MK2LD motor.

The MK2 versions were introduced in April 1998. The cylinder has a

slightly increased diameter and requires a modified piston assembly

and piston sealing. Otherwise the MK2 versions are identical to the

previous HLD350 and HLD2000L. The modified units have got a MK2

added to the type designation on the product label and applies from the

following serial numbers and onwards.

The basic specifications are:

Art. no. Ser. no. Description

21113303 545H36 HLD350 MK2 (200 mm stroke)

21113311 545H36 HLD350 MK2S (split version)

21113360 4154H69 HLD2000 MK2L (long version, 340 mm

stroke)

21113386 4154H610 HLD2000 MK2LS (long, split version)

21113345 3383H68 HLD2000 MK2D (dual cylinder version,

200 mm stroke)

21113402 4154H611 HLD2000 MK2LD (long dual cylinder

version)

In this manual HLD is used as a general term for all models. The MK2

designation is added only when specifically required for parts

identifications.

All HLD models are supplied with environmentally friendly synthetic

hydraulic oil with designation of type Hydralen 32 (viscosity 32 cSt).

This oil can without problem substitute/blend with ordinary hydraulic

oil with equivalent viscosity (between 15 and 40 cSt)

Simrad Hydraulic Linear Drive

6 20220109E

GENERELT

HLD350 MK2 og HLD2000 MK2 er hydrauliske lineære drivenheter

beregnet for båter med mekaniske styresystemer som kabel- og

wirestyring (Edson, Whitlock, Teleflex).

Den består av en kompakt sammenbygget enhet som inneholder

reverserbar hydraulisk pumpe, balansert hydraulisk sylinder, by-pass

ventil og oljetank.

På grunn av den direkte tilkoblingen til roret vil den lineære

drivenheten kunne brukes selv om håndstyringen skulle svikte, noe

som gir større sikkerhet.

Når autopiloten er avslått eller mister spenningen, vil by-pass ventilen

åpne slik at roret kan beveges uhindret ved hjelp av den mekaniske

styringen.

HLD350 MK2 og HLD2000 MK2L etterfølger de tidligere modellene

HLD350 og HLD2000L. Manualen omhandler også HLD2000

MK2D. Denne modellen baserer seg på samme hoveddeler som

HLD350 MK2, men bruker samme motor som HLD2000 MK2LD.

MK2 versjonen ble introdusert i april 1998. Sylinderen har en noe

større diameter og krever et modifisert stempel og stempelforing.

Ellers er MK2 versjonene identiske med HLD350 og HLD2000L.

Modifiserte enheter har fått tilføyd MK2 på produktmerkelappen og

modifikasjonen er gjort gjeldende fra følgende serienummer:

Art. nr. Ser. nr. Beskrivelse

21113303 545H36 HLD350 MK2 (200 mm slaglengde)

21113311 545H36 HLD350 MK2S (delt utgave)

21113360 4154H69 HLD2000 MK2L (lang utgave, 340 mm

slaglengde)

21113386 4154H610 HLD2000 MK2LS (lang, delt utgave)

21113345 3383H68 HLD2000 MK2D (dobbel sylinder,

200 mm slaglengde)

21113402 4154H611 HLD2000 MK2LD (lang, dobbel sylinder)

I denne manualen brukes HLD som en generell betegnelse for alle

modeller. MK2 er kun brukt når det er behov for å identifisere deler.

Alle HLD modeller leveres med en syntetisk, miljøvennlig

hydraulikkolje av typen Hydralen 32 (Viskositet 32 cSt). Denne oljen

kan uten problem erstatte/blandes med vanlig hydrolikkolje med

tilsvarende viskositet (mellom 15 og 40 cSt).

Instruction manual

20220109E 7

2TECHNICAL SPECIFICATIONS

2.1 Standard version

Motor voltage:................................12V DC

Max. current HLD350/2000L: .......10/20A

Average power consumption: ........40 – 60 W

Peak thrust HLD350/2000L: ..........350kp / 500kp

Continuous duty HLD350/2000L: .250kp / 390kp

Max. speed HLD350/2000L: .........10 sec./17 sec. full travel

(Adjustable in the autopilot

electronics)

Stroke: ............................................200mm / 340mm

Overall length with piston in

middle position:.............................. 578mm / 858mm

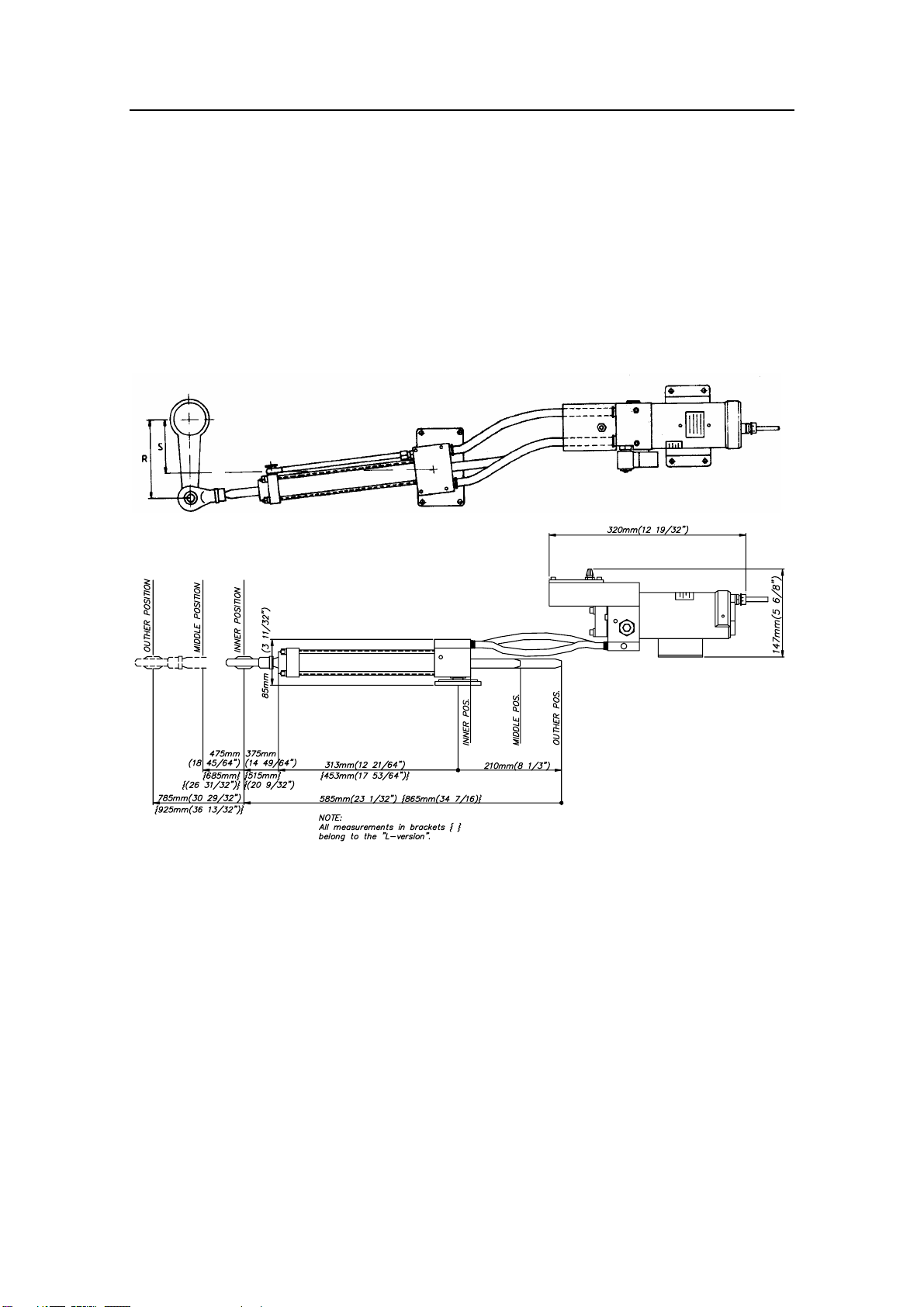

Dimensions:.................................... See fig. 1

Hydraulic oil: .............Hydralen 32, High quality environmentally

friendly, synthetic hydraulic oil.

Alternative oil: ........... Norol HM32, Shell Tellus 27, Esso HP15 and

Yukong Supervis AW32/X32.)

Viscosity 15-40 cSt at 40°C.

Figure 1 HLD dimensions (shown with Fracmo motor)

{350mm (13 ¾”)}

Simrad Hydraulic Linear Drive

8 20220109E

2.2 Split version

To obtain good flexibility in the installation of the HLD, a split

version is available.

The hydraulic cylinder and the motor/pump-unit are made as separate

units with provisions to connect hydraulic hoses between the two.

Modifications have been made on the pump housing for this purpose.

The split version is available with standard (200 mm) or long stroke

(340 mm) and with hose lengths of 1 m (3 ft).

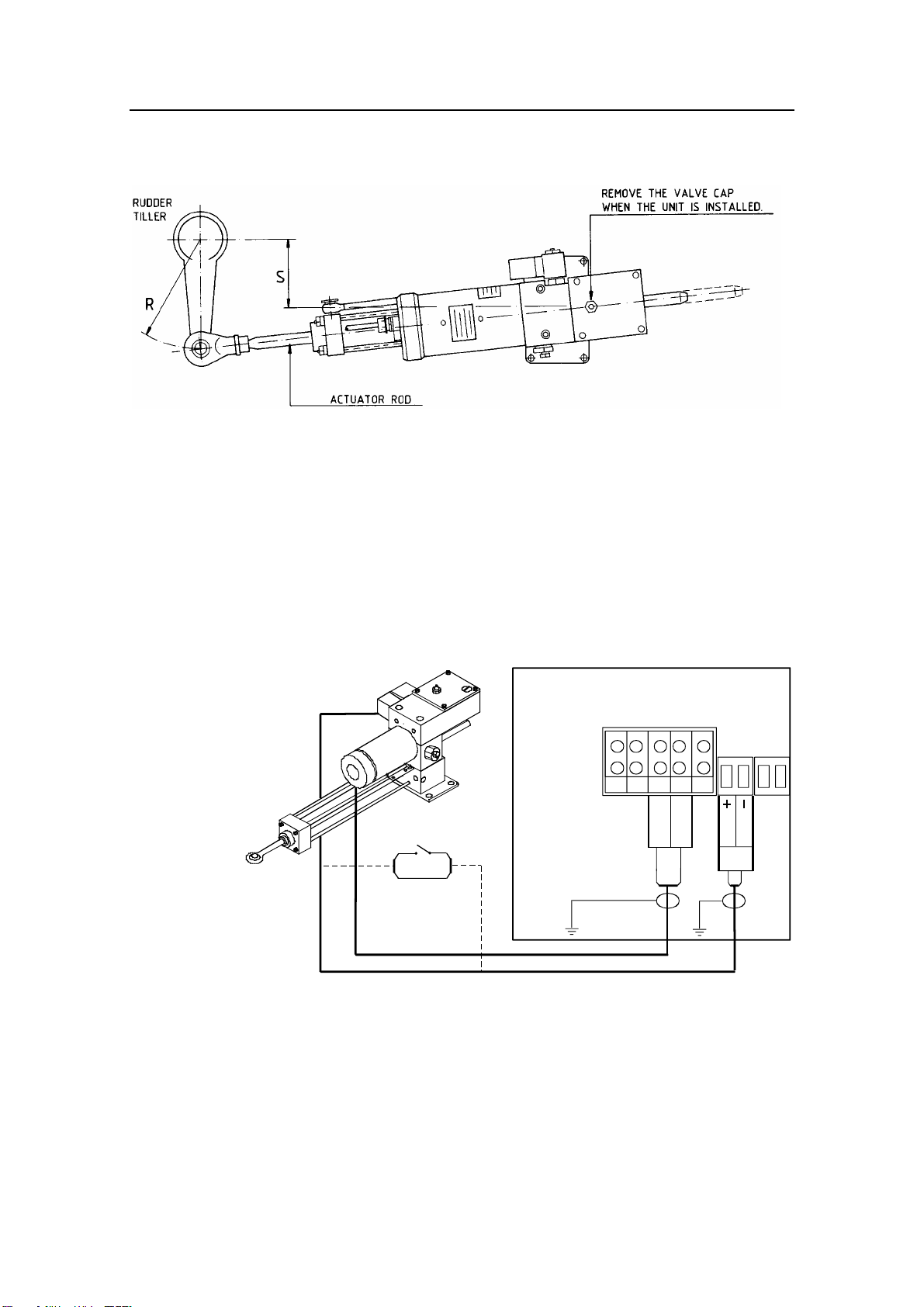

Figure 2 HLD Split version (Shown with Fracmo type motor)

For å oppnå best mulig fleksibilitet ved installasjon er enheten

tilgjengelig i delt utgave.

Hydraulisk sylinder og motor/pumpeenhet er laget som separate

enheter for sammenkobling ved hjelp av hydraulikk-slanger. I denne

forbindelse er det gjort små modifikasjoner på de to enhetene.

Delt utgave kan leveres både med standard slaglengde (200 mm)og

med lang slaglengde (340 mm), og med slanger på 1,0 m.

Instruction manual

20220109E 9

2.3 Dual cylinder version

This model meets the requirement for increased torque without

increasing the radial forces on the rudder stock.

It combines a powerful reversible pump (RPU300) with two cylinders

having the standard stroke or long stroke. 4 flexible hoses of 1 m (3 ft)

connect the pump to the cylinders.

By connecting the cylinders as shown, the radial forces are balanced

out, whilst a double torque has been achieved.

The dual cylinder version is for 24V DC operation only.

Figure 3 HLD Dual cylinder (Shown with Fracmo type motor)

Denne utgaven med doble sylindere er utviklet for å øke dreie-

momentet uten å øke de radielle kreftene som virker på rorstammen.

Den kombinerer en kraftigere reverserbar pumpe (RPU300), med to

sylindere med standard slaglengde, eventuelt med lang slaglengde. 4

oljeslanger på 1 m forbinder pumpen med sylindrene. Ved å montere

sylindrene som vist på figuren får man balansert de radielle kreftene,

samtidig som dobbelt dreiemoment oppnås.

Den doble sylinderversjonen er kun beregnet for 24V DC.

Simrad Hydraulic Linear Drive

10 20220109E

2.4 Comparison chart for HLD MK2 versions

MODEL MOTOR

VOLTS

AUTOPILOT

COMPUTER/

JUNCTION

UNIT

MAX

STROKE

mm (in.)

PEAK

THRUST

kg (lb.)

MAX

RUDDER

TORQUE

Nm

(lb.in.)

HARD-

OVER

TIME

sec.

(30% load)

PWR.

CON-

SUMP.

TILLER

ARM

mm

(in.)

HLD350

HLD350S

12V AC10,

J3000X

200 (7,9) 350

(770)

610

(5400)

12 3,5-10 A 175

(6,9)

HLD2000L

HLD2000LS

12V AC20,

J300X

340 (13,4) 500

(1100)

1460

(12850)

12 5-16 A 298

(11,7)

HLD2000D 24V AC20,

J300X

200 (7,9) 1050

(2310)

1800

(15900)

9 5-16 A 175

(6,9)

HLD2000LD 24V AC20,

J300X

340 (13,4) 1050

(2310)

3180

(28000)

15 5-16 A 298

(11,7)

Steeringgearinterface:Connectstoquadrantortiller.

1. The autopilot computer/junction unit steps down the motor voltage

when operating from 24V or 32V mains.

2. The specified computer/junction unit is necessary to achieve max

drive unit capacity.

3. Recommended operational thrust or torque is 70% of listed value.

4. Typical average power consumption is 40% of listed maximum

value.

Rortilkobling: Kobles til kvadrant eller rorkult.

1. Autopilotcomputeren/koblingsenheten regulerer ned

motorspenningen ved 24V eller 32V nettspenning.

2. Spesifisert computer/koblingsenhet er nødvendig for å oppnå

maksimal kapasitet fra drivenhet.

3. Anbefalt skyvkraft eller moment ved drift er 70% av oppgitt verdi.

4. Gjennomsnittlig effektforbruk er typisk 40% av oppgitt

maksimumsverdi.

Instruction manual

20220109E 11

Fi

g

ure 4 HLD350 Installation dia

g

ram Fi

g

ure 5 HLD2000L Installation dia

g

ram

3INSTALLATION

Refer to table in section 2.4 to verify that appropriate HLD model is

selected for your boat.

If there is any doubt as to whether HLD350/HLD2000L can be

installed, this can be clarified by undertaking the calculations shown

in the appendix.

3.1 Mechanical installation

Rudder and actuator rod is set to midposition. To obtain maximum

and smooth thrust over the actuator's complete stroke, the HLD should

be installed in accordance with fig. 6. The distances R and S for

different rudder angles are found in the diagram in fig. 4 and 5.

The HLD should be fitted with the enclosed safety connector between

actuator and tiller to ensure quick disconnection in emergency

situations.

Note ! Drill and tap the rudder tiller (M12x1.75) to secure the bolt firmly.

Caution ! Do never install the unit upside down! (The air valve should be

facing upwards.) The HLD must be installed horizontally only. No

more than

±

5 degrees tilt is allowed at any position, as illustrated on

figure 1. The HLD should not act as an end stop for the rudder.

8

10

12

14

16

18

20

22

24

25 30 35 40 45

cm

R

S

RUDDER ANGLE / RORVINKEL

50 55 60

DISTANCE R AND S

AVSTAND R OG S

DEGREES

GRADER

8

12

16

20

24

28

32

36

40

25 30 35 40 45

cm

R

S

RUDDER ANGLE / RORVINKEL

50 55 60

DISTANCE R AND S

AVSTAND R OG S

DEGREES

GRADER

Simrad Hydraulic Linear Drive

12 20220109E

Remove the valve cap on the tank when the unit is installed.

Figure 6 HLD Installation

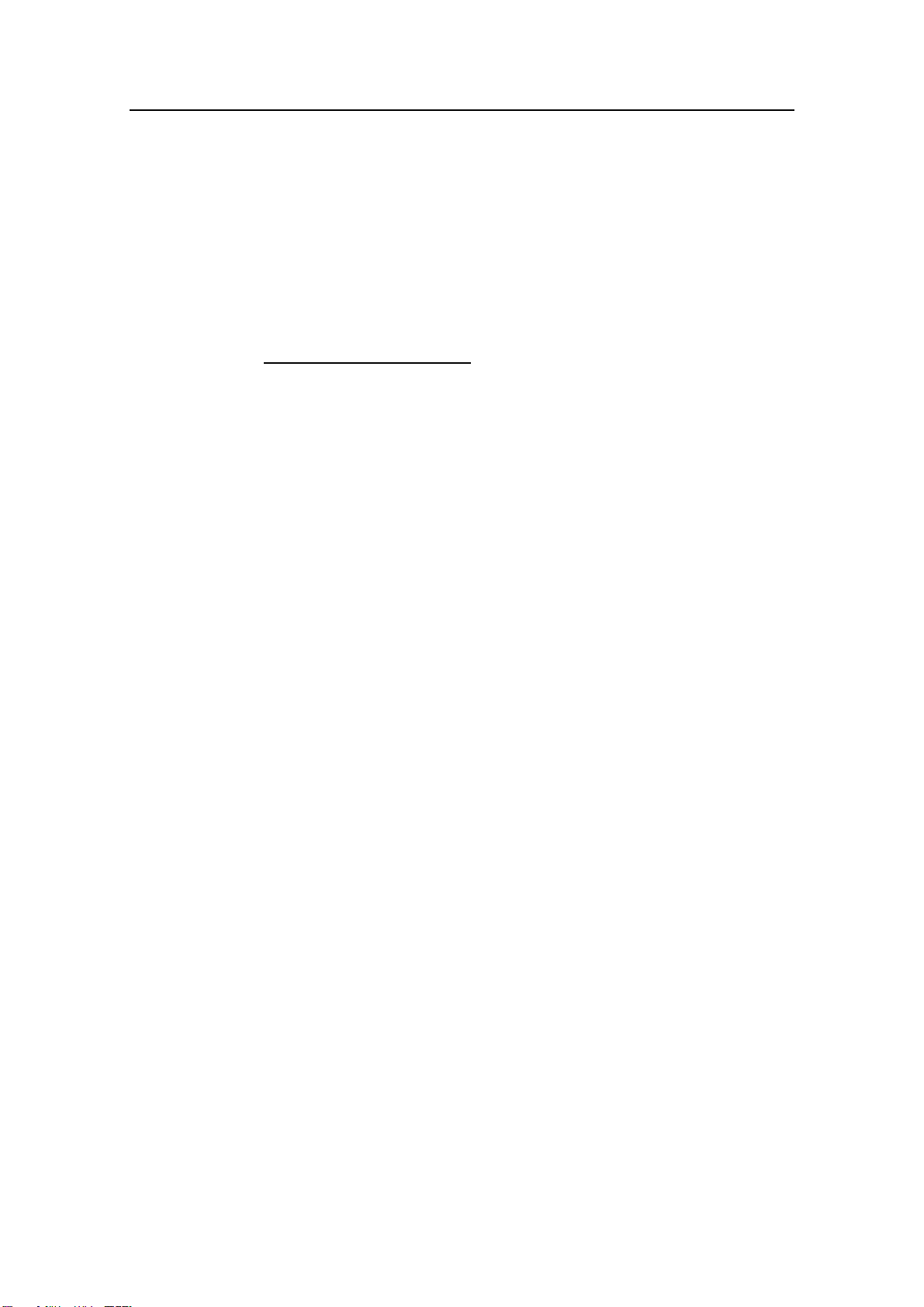

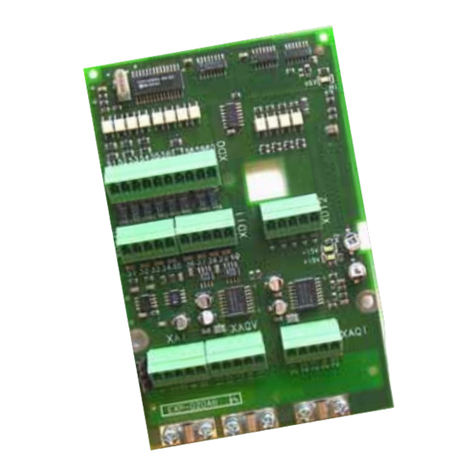

3.2 Electrical connection

AC10/AC20 Autopilot Computer,

J300X/J3000X Junction Unit

The HLD is connected to the autopilot via AC10, AC20, J300X or

J3000X according to the following diagram:

POWER PCB

TB1 TB2 TB3 TB4 TB5

TB6

Drive

Engage

Sol. -Motor

Sol. -Motor

TB7

HYDRAULIC

LINEAR DRIVE

Single pole

clutch/bypass

switch

Figure 7 HLD connection to ACXX and J3XX

J101A Junction Unit

The HLD can also be connected to previous models autopilots using

the J45A, J101A or J1000 Junction units. The Junction Unit controls

the current to the motor and the bypass valve. The Junction Unit also

has built-in speed regulation of the HLD, which allows rudder speed

Instruction manual

20220109E 13

adjustment (i.e. the steering performance of the boat when autopilot

steering) after installation of the system.

Note that for the HLD350 (not the HLD2000L) the trim potentiometer

RV1 in J1000/J101A/J45A should be adjusted to approx. 2/3 of full

C.W. position.

The J1000/J101A/J45A also has a built-in current limiter to prevent

overload of the motor (Max. current is 20A).

Motor/bypass connection

The bypass valve is connected to terminal 13 and 14 in

J45A/J101A/J1000, and is polarity independent.

The motor is connected to terminal A and B in J45A/J101A/J1000.

Interchange of A and B will change the direction of rotation.

Cable for the motor supply voltage from the ship mains must be at

least 2x4mm2(AWG10), and fused according to the table enclosed

with the J101A/J1000.

INSTALLASJON

Kontroller mot tabellen under seksjon 2.4 at riktig HLD model er

valgt.

Er det tvil om hvorvidt HLD350 eller HLD2000L skal velges, kan

dette klargjøres ut fra beregningene som er vist i tillegget bak i

manualen.

Mekanisk installasjon

Plasser stempelstang og ror i midtstilling. HLD monteres slik fig. 6

viser for å få maksimal skyvkraft langs hele stempelstangens

vandring. Avstandene R og S ved de forskjellige rorvinkler finnes i

diagram fig. 4 og 5.

HLD er utstyrt med hurtigkopling mellom stempelstang og rorkult

som tillater hurtig frakobling i nødssituasjoner.

Bruk M12x1,75 gjengetapp og gjeng opp i rorkult.

HLD må aldri monteres opp ned! (Lufteventil på tank skal peke

oppover). Enheten må monteres horisontalt, og slik at avviket fra

horisontalplanet aldri overstiger ±5 grader, slik som illustrert på

fig. 1. HLD må ikke monteres slik at den fungerer som endestopp

for roret.

Husk å skru av ventilhetten på tanken etter at enheten er montert.

Simrad Hydraulic Linear Drive

14 20220109E

Elektrisk tilkobling

AC10/AC20 autopilotcomputer,

J300X/J3000X koblingsenhet

HLD kobles til autopiloten via AC10, AC20, J300X eller J3000X i

henhold til fig. 7.

J101A koblingsenhet

HLD kan også kobles til tidligere autopilotmodeller som bruker

J101A eller J1000 koblingsenheter. Koblingsenhetene kontrollerer

strømmen til motoren og by-pass ventilen. Koblingsenheten har også

innebygget hastighetsregulering av HLD, noe som gir anledning til å

justere rorhastighet (og dermed båtens styreegenskaper med autopilot)

etter at systemet er installert.

Ved bruk av HLD350 (gjelder ikke HLD2000L) bør trimme-

potensiometer RV1 i J45A/J101A/J1000settes til ca. 2/3 av fullt

område.

I J45A/J101A/J1000er det også innebygget en strømbegrenser som

hindrer overbelastning av motor (maks. strøm er 20A).

Kobling av motor/bypassventil:

Bypassventil kobles til terminal 13 og 14 i J45A/J101A/J1000 og er

polaritetsuavhengig.

Motoren kobles til terminal A og B i J45A/J101A/J1000. Ombytting

av A og B vil snu motorens dreieretning.

Kabel for motorspenning fra båtens fordelingsskap må være minst

2x4mm2og sikret i.h.h.t. tabell vedlagt i J45A/J101A/J1000.

Instruction manual

20220109E 15

4CONSTRUCTION AND PRINCIPLE OF

OPERATION

The HLD is delivered completely assembled with tank, reversible

hydraulic pump and a balanced hydraulic cylinder. The HLD is

therefore a completely closed system.

4.1 Tank

The tank is machined out of

solid aluminium and all

necessary oil ways are

drilled out.

A bypass valve is mounted

in the tank, to allow the

mechanical steering system

to be used, when the

autopilot is not in operation.

The bypass valve is a

standard ON/OFF solenoid

valve, normally open.

When the autopilot is in

STBY mode, the solenoid

valve will be in open

position.

When AUTO or NAV mode

is selected, the solenoid

valve will be in closed

position.

The solenoid valve opens

immediately when the

autopilot is switched off, and

handsteering is allowed.

Previous versions

An early version of HLD350

and HLD350S did not have

check valves. The following

serial no. codes can identify it:

H30 (HLD350) and H31 (HLD350S).

The principle of operation was similar to that of HLD2000L. The

(suction) valves, however, operated as combined suction and (non-

return) check valves controlled by internal pressure and direction of oil

flow. The resulting effect was a smoother check valve operation as

Functional diagram

1. Electrical motor (Elektromotor)

2. Gear pump (Tannhjulspumpe)

3. Suction valve (Innsugingsventil)

4. Check valve (Tilbakeslagsventil)

5. Oil tank (Oljetank)

6. By-pass valve (By-pass ventil)

7. Hydraulic actuator (Hydraulisk

sylinder)

7

6

M

44

33

2

1

5

Simrad Hydraulic Linear Drive

16 20220109E

compared to the ones with separate check valves. It should be observed

however, that this version does not have the extra protection against

internal leakage (bypass) as the models with separate check valves.

4.2 Reversible Hydraulic Pump

The pump consists of valve block, reversible gear pump, pressure

operated check (non-return) valves, electric permanent magnet motor,

suction valves and slide.

The pump is reversible, i.e. the motor changes direction of rotation

and the gear pump delivers oil to that side of the rudder cylinder

dictated by the signal from the autopilot. When the motor is running,

the pressurised (or delivery) side will hold both check valves open,

using direct oil pressure upon the valve on the delivery side. This oil

pressure is also used to push a slide to open the valve on the suction

side.

When the motor stops, the spring in the check valve on the suction

side returns the slide to the neutral position. Both check valves are

now closed and the rudder cylinder locked. Both sides of the gear

pump are able to suck oil from the tank through the suction valves.

4.3 Hydraulic Rudder Cylinder

The rudder cylinder consists of the cylinder itself, actuator, actuator

rod, ball joint and base plate.

The actuator rod runs through the cylinder. The actuator area is

identical on both sides, and this balances the cylinder.

Figure 8 HLD Assembly drawing (N3-111832)

(Shown with Fracmo type motor)

Instruction manual

20220109E 17

KONSTRUKSJON OG VIRKEMÅTE

HLD leveres komplett sammenbygget med tank, reverserbar

hydraulisk pumpe og balansert hydraulisk sylinder. Den arbeider

dermed i et lukket system.

Tank

Tanken er frest ut av massiv aluminium og nødvendige oljeløp er

utboret.

I tanken er det montert en bypass-ventil for at det mekaniske

styresystemet skal kunne brukes når autopiloten ikke er i bruk.

Bypass-ventilen er en standard Av/På magnetventil som normalt er

åpen.

Magnetventilen er åpen når autopiloten er i STBY og lukket når

autopiloten er i AUTO eller NAV. Ventilen åpner umiddelbart når

autopiloten slås av slik at håndstyring kan benyttes.

Tidligere versjoner

En tidligere versjon av HLD350 og HLD350S har ikke

tilbakeslagsventil. Denne versjonen identifiseres med følgende serie

nr. kode: H30 (HLD350) og H31 (HLD350S).

Betjeningsprinsippet var tilsvarende som for HLD2000L.

Innsugnings-ventilene fungerte imidlertid som kombinerte innsugings-

og tilbakeslagsventiler kontrollert av det interne trykket og retningen

av oljestrømmen. Effekten av dette var en jevnere sperrefunksjon

sammenlignet med enheter med egen tilbakeslagsventil. Denne

versjonen gir imidlertid ikke den ekstra beskyttelse mot intern

lekkasje som den med egen tilbakeslagsventil gir.

Reverserbar hydraulisk pumpe

Pumpen består av ventilblokk, pumpeenhet, motor med permanente

magneter, tilbakeslagsventiler og sleide.

Pumpen er reverserbar, dvs. at motoren kan endre dreieretning og

tannhjulspumpen vil levere oljen enten til den ene eller andre enden av

rorsylinderen, avhengig av signalene fra autopiloten.

Når motoren går, vil pumpens trykkside holde begge de trykkstyrte

tilbakeslagsventilene åpne. Tilbakeslagsventilen på trykksiden åpnes

direkte av oljetrykket, mens den på sugesiden blir åpnet av en sleide

som skyves over av oljetrykket på trykksiden.

Når signalet fra piloten opphører, vil fjæren i tilbakeslagsventilen på

sugesiden trykke sleiden tilbake til nøytralstilling. Begge

tilbakeslagsventilene vil da være lukket. Den hydrauliske sylinderen

Simrad Hydraulic Linear Drive

18 20220109E

er dermed låst. Begge sider av tannhjulspumpen kan suge fra tank via

innsugningsventiler.

Hydraulisk rorsylinder

Rorsylinderen består av sylinderrør, stempelstang med stempel,

endestykke og fot.

Stempelstangen er gjennomgående. Stempelarealet er likt på begge

sider, og sylinderen er dermed balansert.

This manual suits for next models

1

Table of contents

Popular DC Drive manuals by other brands

gefran

gefran EXP-D20A6 instruction manual

REXROTH

REXROTH IndraDrive Project planning manual

gefran

gefran ADV200 WA Quick start up guide, Specification and installation

YASKAWA

YASKAWA CIMR-JB Series Installation & start-up manual

GE

GE Fuji Electric AF-300ES instructions

SOMFY

SOMFY Sonesse Ultra 50 instructions