3/24

TABLE OF CONTENTS

1Before operation 4

1.1 Precautions ............................................................................................................ 4

1.1.1 Put the Safety First ..................................................................................................... 4

1.1.2 Operation..................................................................................................................... 5

1.1.3 Check and Repair ........................................................................................................ 5

2Drive Specification and Dimension 6

2.1 Specifications of Drive............................................................................................ 6

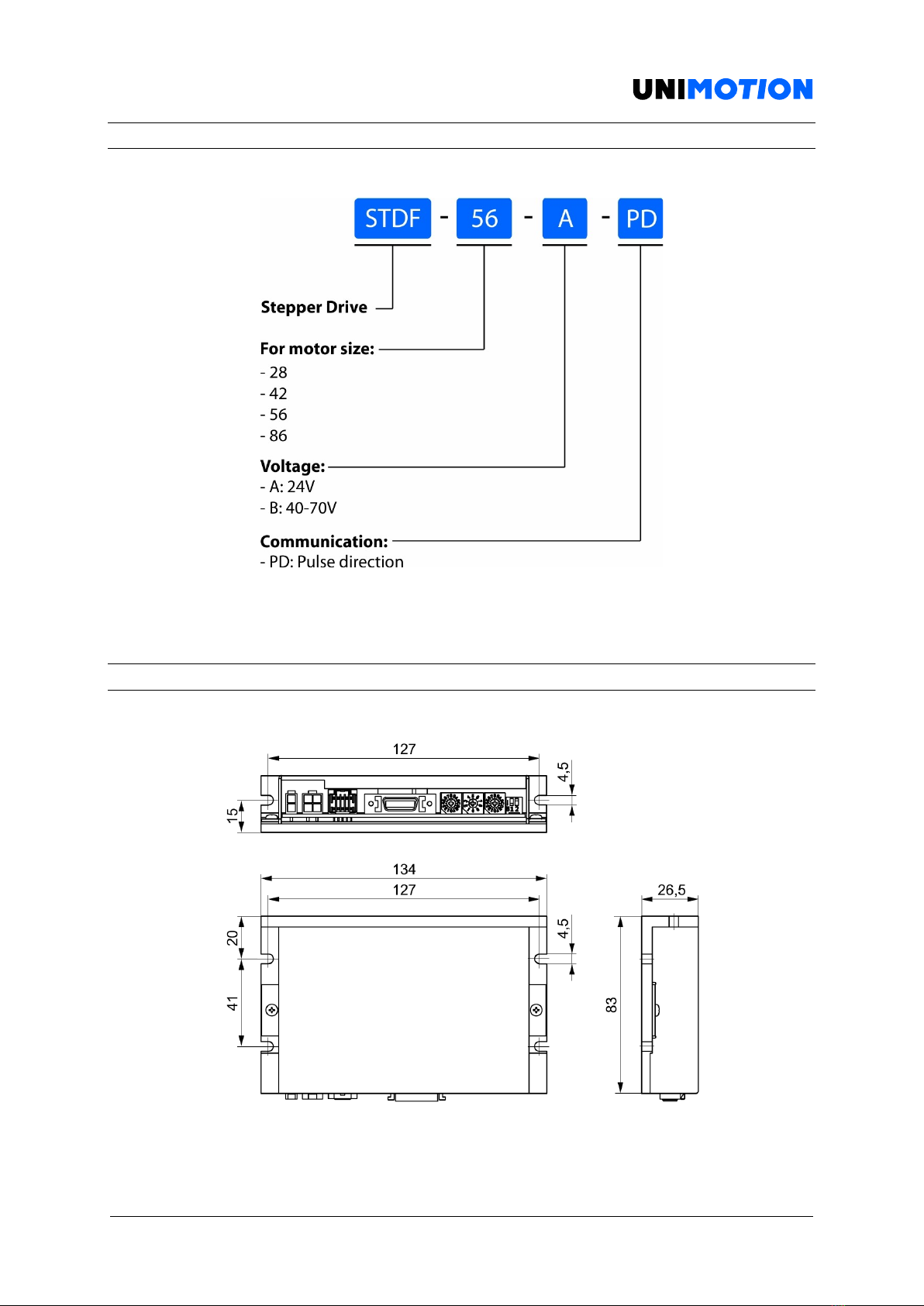

2.2 Model naming......................................................................................................... 7

2.3 Product dimensions................................................................................................ 7

3Installation 8

3.1 Precautions of installation ...................................................................................... 8

3.2 Appearance and part name ..................................................................................... 8

4Brake Operation Timing Chart 9

5Settings and Operation 10

5.1 Drive Status LED ................................................................................................... 10

5.2 Pulse Input Setting Switch (SW1.1) ....................................................................... 11

5.3 Rotational Direction Setting Switch (SW1.2) .......................................................... 12

5.4 Resolution Setting Switch (SW3)........................................................................... 12

5.5 Position Controller Gain Setting Switch (SW2)....................................................... 13

5.6 In-Position Value Setting Switch (SW4)................................................................. 14

5.7 Encoder Connector (CN2) ..................................................................................... 15

5.8 Input/Output Signal Connector (CN1) .................................................................... 15

5.9 Motor Connector (CN3)......................................................................................... 16

5.10 Power Connector (CN4)..................................................................................... 16

6System Configuration 17

6.1 External Wiring Diagram........................................................................................ 18

7Control Signal Input/Output Description 19

7.1 Input Signal .......................................................................................................... 19

7.2 CW, CCW Input ..................................................................................................... 19

7.3 Servo On/Off Input................................................................................................ 20

7.4 Alarm Reset Input ................................................................................................. 20

7.5 Output signal ........................................................................................................ 21

7.6 Alarm Output ........................................................................................................ 21

7.7 In-Position Output ................................................................................................ 22

7.8 Encoder Signal Output .......................................................................................... 22