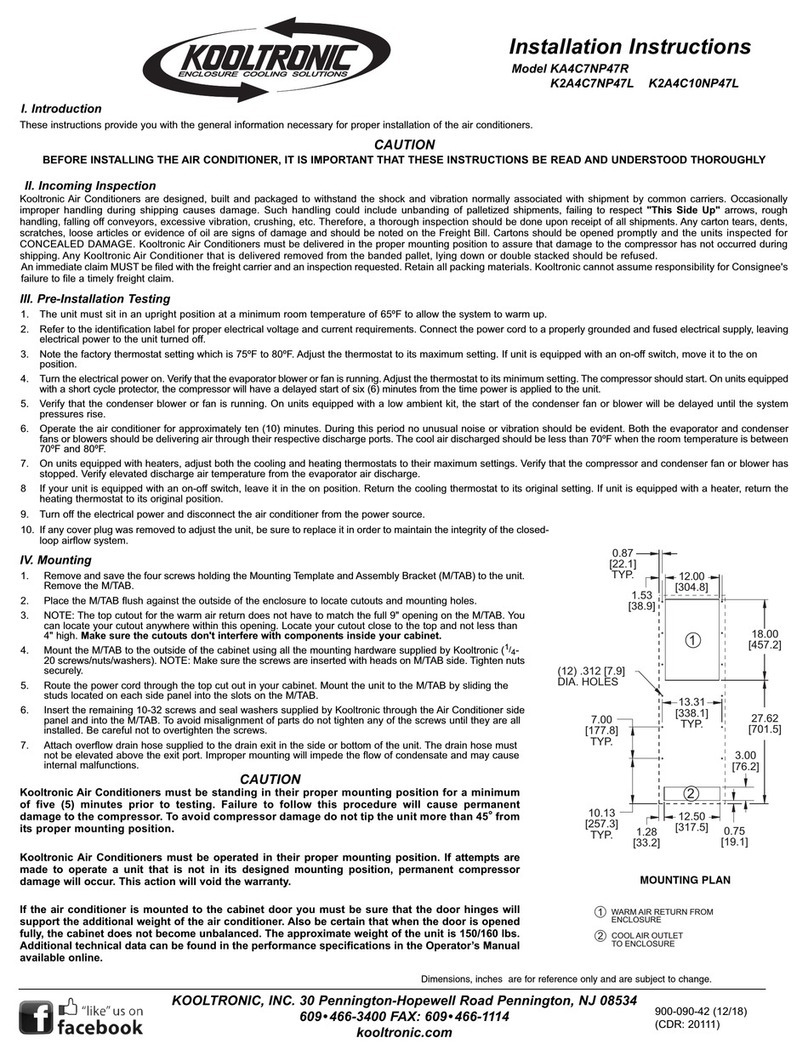

V. Principles of Operation

Kooltronic Air Conditioners are required when the equipment

operating temperature must be kept near or lower than the

ambient room temperature, and/or the cabinet must be sealed

from dust, fumes, oil, corrosives and other contaminants. These

Air Conditioners utilize a "Closed-Loop Cooling System" to

ensure optimum performance of the installed components.

Closed-Loop cooling seals the electronic enclosure from hostile

elements in the environment. Two separate circulation systems

are employed. The internal system cools and dehumidifies the

air inside the cabinet, totally isolating the sensitive electronics

and other components from the environment. The external

system uses circulating ambient air or water to discharge the

heat removed from the electronics. The heat is dissipated from

the enclosure by means of the vapor compression refrigeration

cycle. This takes place in a hermetically-sealed refrigeration

system, utilizing either an air-cooled or water-cooled condenser

heat exchanger. The warm air inside the enclosure is drawn

through the evaporator coil where it is cooled, dehumidified and

returned.

Any enclosure moisture accumulated on the evaporator coil is collected in the condensate tray and removed

through the drain tube to the condensate evaporator. Condensate evaporates in the condensate evaporator

and is released to the ambient air by the condenser impeller.

The heat removed through the evaporator coil is transferred by the compressed refrigerant to the condenser

coil. Ambient air is then passed through the condenser coil, where it absorbs the heat and is then discharged

to the environment.

To help eliminate compressor cycling, a two stage thermostat is used in this unit, with a thermostat sensor

located in the return air stream of the enclosure. The first stage, which controls the compressor, has a set

point of 64°F (18°C).The second stage, which controls the condenser blower (fan), has a set point of 66°F

(19°C). The first stage has a temperature differential of 11°F (6°C), and the second stage has a temperature

differential of 0.5°F. When the return air temperature is above 70°F the air conditioner will run constantly.

When the return air temperature drops below 66°F the thermostat’s second stage will start to cycle the

condenser blower and the return air will fluctuate from 64°F to 70°F. In conditions of very low ambient

temperature and low internal load the return temperature could drop below 64°F. In this case the thermostat’s

first stage will start to cycle the compressor and the return air temperature will fluctuate from 63°F to 75°F.

In reality this situation would occur rarely, and then only for a short period of time. The advantage of a two

stage thermostat is that it avoids compressor cycling and controls the return air temperature to a very narrow

temperature range of 6°F; from 64°F to 70°F.

The heater kit consists of a heater, a heat control thermostat and a heater limiter. The heater control

thermostat is a bimetal disk with a fixed set point of 60°F. When the entering evaporator air temperature rises

above 60°F the heater shuts off, and when the evaporator air temperature falls below 40°F the heater will

engage. The contact points of the alarm thermostat are normally closed. If the entering evaporator air

temperature exceeds 130°F the alarm thermostat contacts open, and when the temperature drops below

130°F the contacts close.

VI. Pre-Installation Testing

Before mounting the air conditioner to the enclosure, test for proper operation. This will verify the shipping

integrity of the system. Please follow the steps below prior to installation.

CAUTION