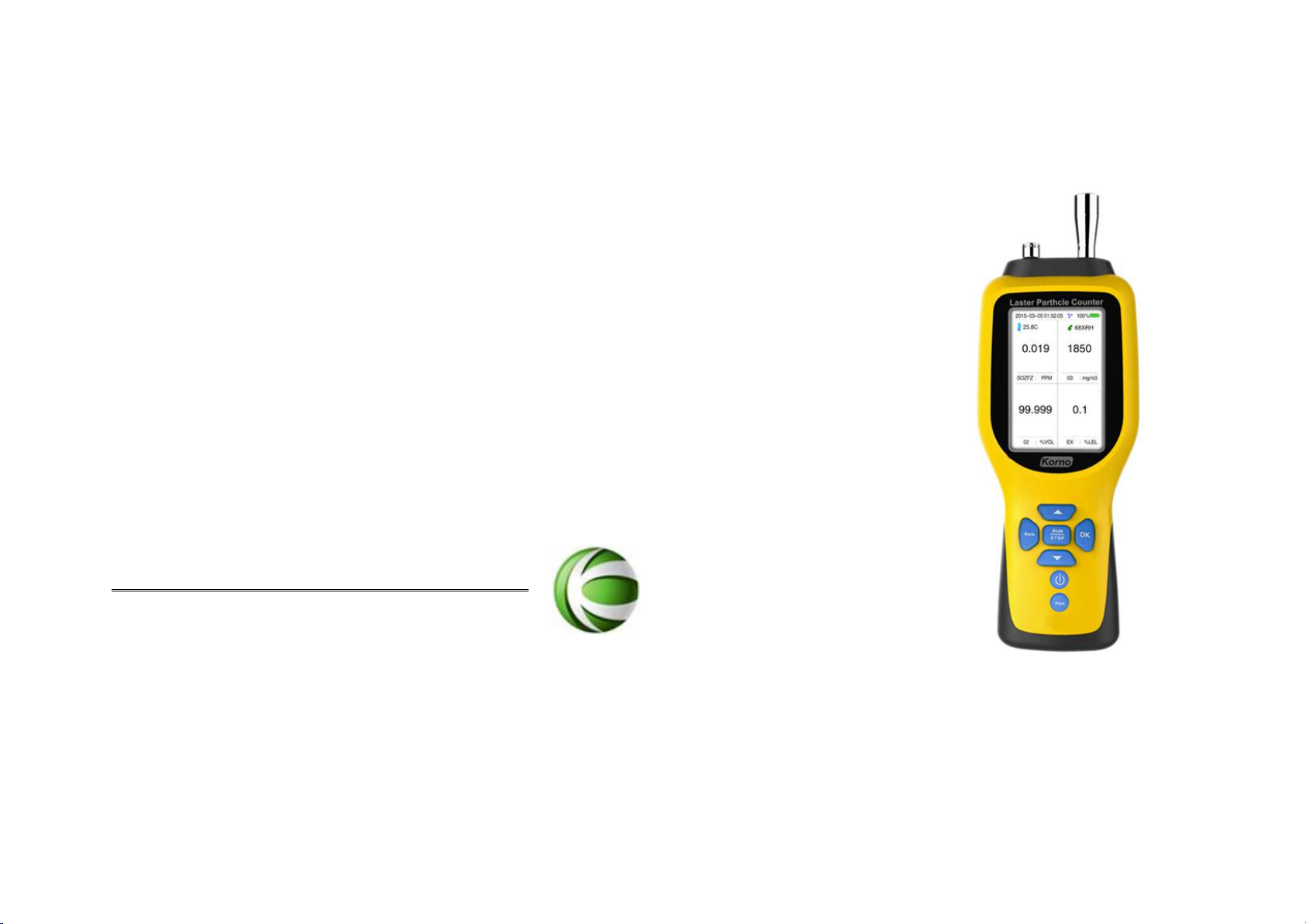

ShenZhen Korno Import&Export Co.,Ltd http://szkorno.en.made-in-china.com

Catalog

Notice.............................................................................................................................................................................................................................................................. 4

1.Product Brief Introduction.........................................................................................................................................................................................................................7

2.Key Feature.................................................................................................................................................................................................................................................8

3.Technical Parameters............................................................................................................................................................................................................................... 9

4.Product Structure..................................................................................................................................................................................................................................... 11

5.Operation Instruction............................................................................................................................................................................................................................... 12

5.1Button Description......................................................................................................................................................................................................................... 12

5.2Power On........................................................................................................................................................................................................................................ 13

5.3Power Off........................................................................................................................................................................................................................................ 14

6.Operation Interface..................................................................................................................................................................................................................................14

6.1 Gas Detection Interface...............................................................................................................................................................................................................14

6.2 Function Menu Instruction...........................................................................................................................................................................................................15

6.2.1 Basic Setting...................................................................................................................................................................................................................... 15

6.2.2 History Data Log................................................................................................................................................................................................................16

6.2.3 RealTime Curve................................................................................................................................................................................................................ 17

6.2.4 Zero Calibration.................................................................................................................................................................................................................18

6.2.5 Target Calibration(Do Not Calibrate Unless You Are Professional)........................................................................................................................ 18

6.2.6 Alarm Settings................................................................................................................................................................................................................... 19

6.2.7 Measure Mode............................................................................................................................................................................................20

6.2.8Store Setting....................................................................................................................................................................................................................... 20

6.2.9 Pringt Setting.............................................................................................................................................................................................. 20

6.2.10 Time Setting.....................................................................................................................................................................................................................20

6.2.11 Factory Setting................................................................................................................................................................................................................ 21

7. Common Faults and Exclusions...........................................................................................................................................................................................................22

8.Concentration Datalog Output Instruction........................................................................................................................................................................................... 24