3

INTRODUCTION

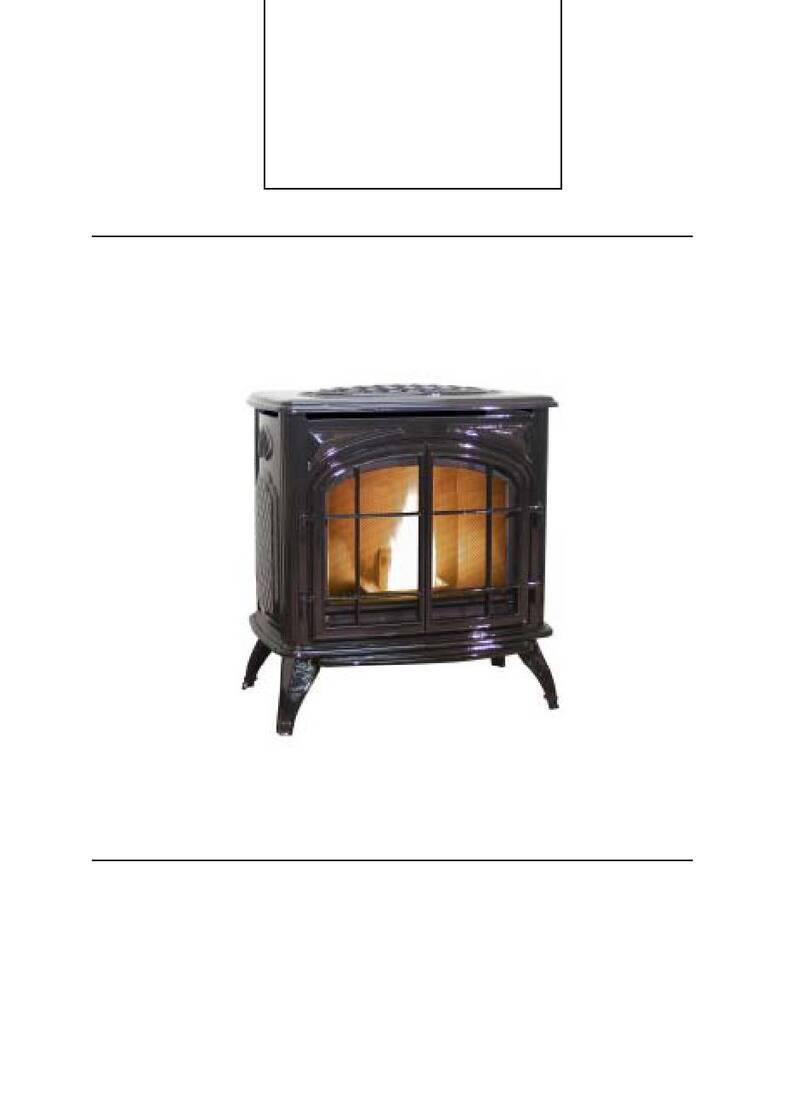

Your KOZI CDVI is a quality gas-burning appliance. With proper installation and

maintenance, it will serve you well with many years of trouble free heating, and the

wonderful ambiance a gas fireplace adds to your home.

Before beginning the installation of your appliance, read these instructions through

completely and consult your local building authority. Install the unit and its’ venting

system only as described in these instructions.

This appliance and its’ approved components are safe when installed according to this

installation manual and are operated as recommended. Unless you use approved

components tested for this appliance, YOU MAY CAUSE A FIRE HAZARD!

The warranty will be voided by APR Industries Ltd. for the following actions:

A) Modification of the appliance or any of the components manufactured by APR

Industries Ltd. unless otherwise permitted by APR Industries Ltd.

B) The use of any component part not approved by APR Industries Ltd. in

combination with this appliance.

C) Installation and/or operation in a manner other than instructed in this manual.

D) The burning of anything other than the type of gas approved for use in this

gas appliance.

APR Industries Ltd. also disclaims any responsibility for the above actions.

This appliance, when installed, must be electrically grounded in accordance with local

codes or, in the absence of local codes, with the NATIONAL ELECTRICAL CODE,

ANSI/NFPA 70 or the CANADIAN ELECTRICAL CODE, CSA C22.1.

The installation must conform to local codes or, in the absence of local codes, with the

NATIONAL FUEL GAS CODE ANSI Z223.1/NFPA 54 or NATURAL GAS AND

PROPANE INSTALLATION CODE CSA B149.1.

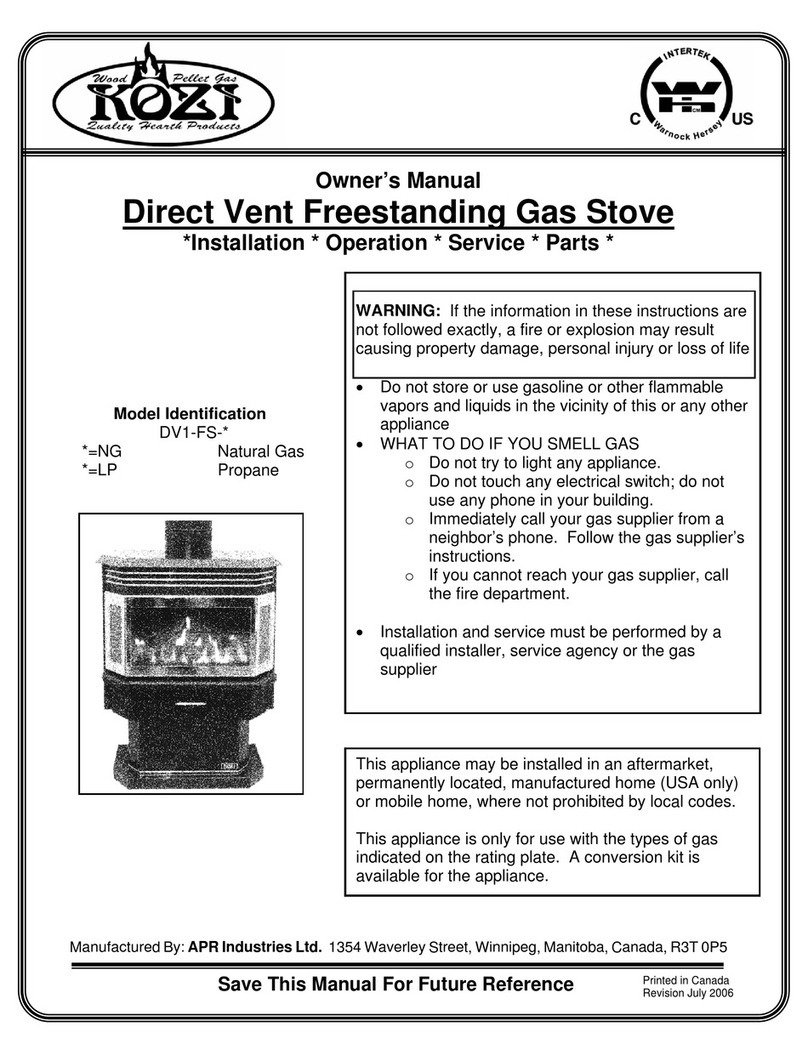

This gas fireplace has been tested and certified for use in the USA and Canada by

Warnock Hersey according to the following Standards; ANSI Z21.88 - 2002/CSA 2.33 –

2002, CAN/CGA 2.17-M91

CHILDREN AND ADULTS SHOULD BE ALERTED TO THE HAZARDS OF HIGH

SURFACE TEMPERATURE AND SHOULD STAY AWAY TO AVOID BURNS OR

CLOTHING IGNITION.

YOUNG CHILDREN SHOULD BE CARFULLY SUPERVISED WHEN THEY ARE IN

THE SAME ROOM AS THE APPLIANCE. TODDLERS, YOUNG CHILDREN AND

OTHERS MAY BE SUSCEPTIBLE TO ACCIDENTAL CONTACT BURNS. A

PHYSICAL BARRIER IS RECOMMENDED IF THERE ARE AT RISK INDIVIDUALS IN

THE HOUSE. TO RESTRICT ACCESS TO A FIREPLACE OR STOVE INSTALL AN

ADJUSTABLE SAFETY GATE TO KEEP TODDLERS, YOUNG CHILDREN AND