KOZI DIRECT VENT GAS STOVE

7

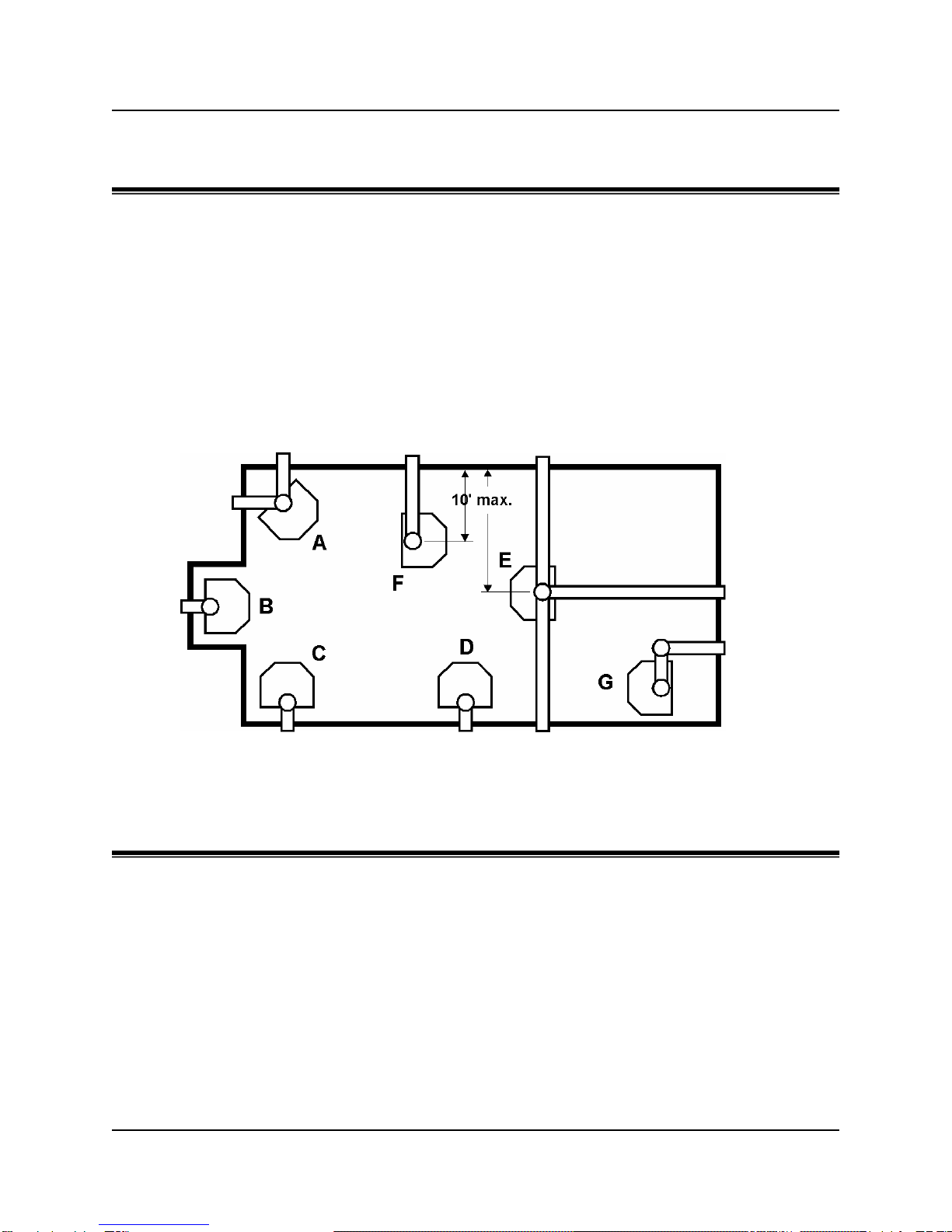

GENERAL INFORMATION:

•Thisappliancemustbe installed on a flat, solid, continuous surface. Thismaybeonthe

floor or the raised surface of a platform to emphasise the visual enjoyment.

•TheKOZI DirectVentFreestandingGasStove has been approvedfortheinstallations

displayed in the following diagram, Fig. 3. This unit has also been approved for

installations employing millivolt thermostats for heat regulation. Installations in Mobile

Homes have been approved as long as the appliance is securely bolted to the frame.

•The installation must conform with local codes or, in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1. A manufactured home (USA only) or mobile home

OEM installation must conform with the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280, or, when such a standard is not applicable, the

StandardforManufacturedHome installations,ANSI/NCSBCSA225.1,orStandard for

Gas Equipped Recreational Vehicles and Mobile Housing, CSA Z240.4.

•The appliance, when installed, must be electrically grounded in accordance with local

codes or, in the absence of local codes, with the National Electrical Code, ANSI/NFPA

70, or the Canadian Electrical Code, CSA C22.1. This appliance is equipped with a

three-prong (grounding) plug for your protection against shock hazard and should be

pluggeddirectly into a properlygroundedthree-prongreceptacle. Donotcutorremove

the grounding prong form this plug.

•The product should be inspected for shipping damage prior to installation and serviced

annually thereafter by a qualified technician.

•This appliance must be connected to the specified vent and termination cap to the

outside of the building. Never vent into another room or inside a building. Ensure that

the vent is properly jointed as per the instruction on page 17.

•To prevent injury or bodily harm, do not allow anyone who is unfamiliar with this

appliance operate it without supervision.

•The efficiency rating of this appliance is a product thermal efficiency rating determined

under continuous operating conditions and was determined independently of any

installed system.

Note: Read these instructions carefully and completely. Failure to follow

them could cause malfunction or damage to the appliance, property

damage, personal injury or fatality. Failure to comply with these

instructions could result in loss of insurance coverage and warranty.