Table of content Kracht GmbH

ii 88025530002-11

Table of content

1 General ................................................................................................................................................................4

1.1 About the documentation ....................................................................................................................................................... 4

1.2 Manufacturer address................................................................................................................................................................ 4

1.3 Symbols........................................................................................................................................................................................... 5

2 Safety...................................................................................................................................................................6

2.1 Intended use.................................................................................................................................................................................. 6

2.2 Personnel qualification and training.................................................................................................................................... 6

2.3 Basic safety instructions............................................................................................................................................................ 7

2.4 Fundamental hazards.................................................................................................................................................................7

3 Device description.............................................................................................................................................. 9

3.1 Functional principle .................................................................................................................................................................... 9

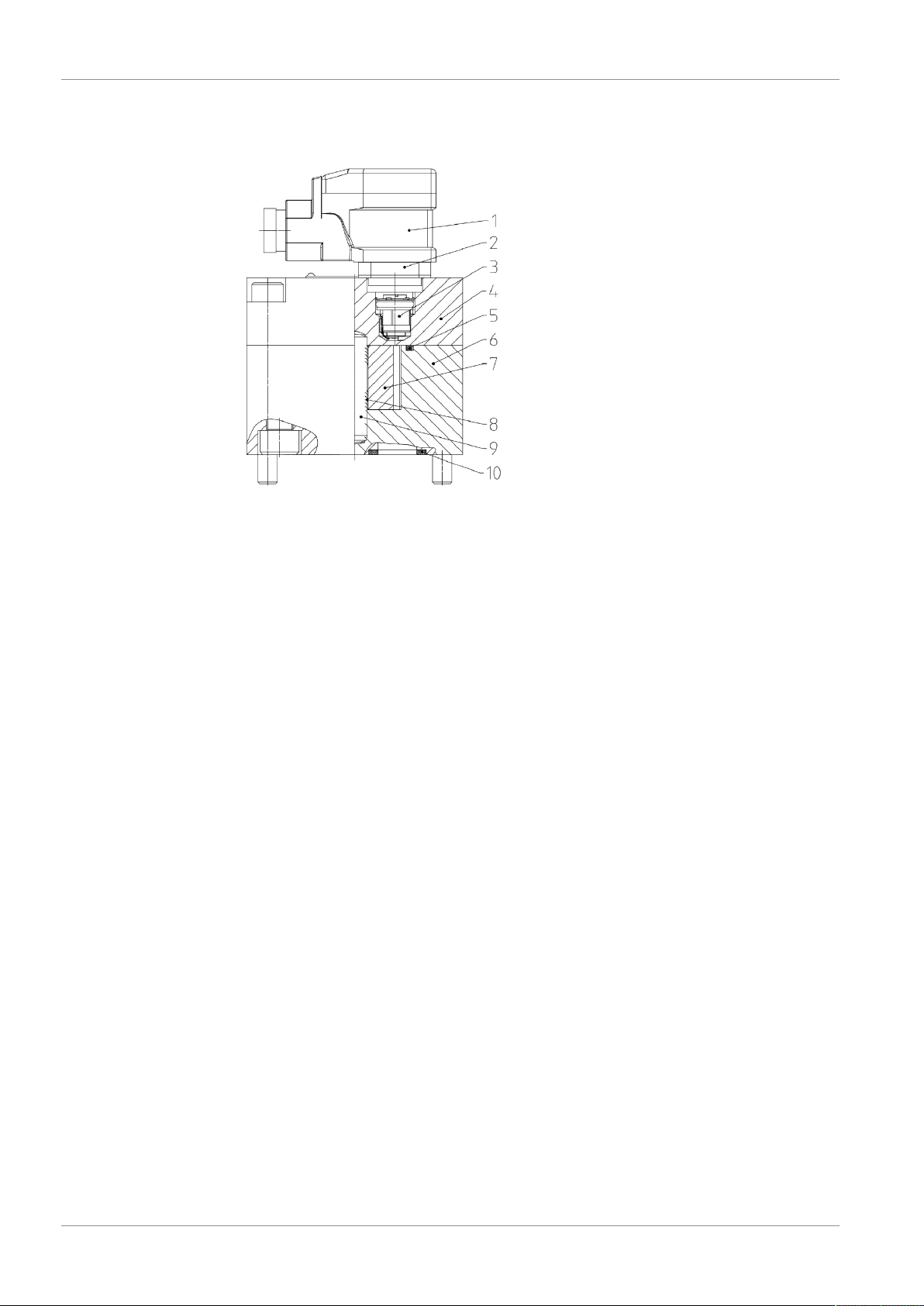

3.2 Basic design.................................................................................................................................................................................10

3.3 Type key ........................................................................................................................................................................................11

3.4 Special numbers.........................................................................................................................................................................12

4 Technical data...................................................................................................................................................13

4.1 General ..........................................................................................................................................................................................13

4.2 Overview nominal sizes...........................................................................................................................................................14

4.3 Permissible temperature range............................................................................................................................................15

4.4 Material data ...............................................................................................................................................................................15

4.5 Weight ...........................................................................................................................................................................................16

4.6 Dimensions ..................................................................................................................................................................................16

5 Transport and storage .....................................................................................................................................17

5.1 General ..........................................................................................................................................................................................17

5.2 Transport.......................................................................................................................................................................................17

5.3 Storage ..........................................................................................................................................................................................17

5.4 Storage conditions....................................................................................................................................................................18

6 Installation ........................................................................................................................................................19

6.1 Important notes about explosion protection.................................................................................................................19

6.2 Mechanical installation............................................................................................................................................................20

6.2.1 Preparation....................................................................................................................................................................20

6.2.2 Plate connection ........................................................................................................................................................21

6.2.3 Pipe connection...........................................................................................................................................................23

6.3 Electrical connection ................................................................................................................................................................23

6.3.1 Preamplifier (S, H , K).................................................................................................................................................23

7 Operation start-up ...........................................................................................................................................25

7.1 Safety instructions for start-up ............................................................................................................................................25

7.2 Preparation...................................................................................................................................................................................25

7.3 Further operation start-up.....................................................................................................................................................25