Table of content Kracht GmbH

ii 88025420002-17

Table of content

1 General ........................................................................................................................................ 4

1.1 About the documentation............................................................................................................................ 4

1.2 Manufacturer address .................................................................................................................................... 4

1.3 Other applicable documents....................................................................................................................... 4

1.4 Symbols................................................................................................................................................................ 5

2 Safety........................................................................................................................................... 6

2.1 Intended use ...................................................................................................................................................... 6

2.2 Personal qualification..................................................................................................................................... 6

2.3 Basic safety instructions ................................................................................................................................ 7

2.4 Fundamental hazards ..................................................................................................................................... 7

3 Device description...................................................................................................................... 9

3.1 Functional principle......................................................................................................................................... 9

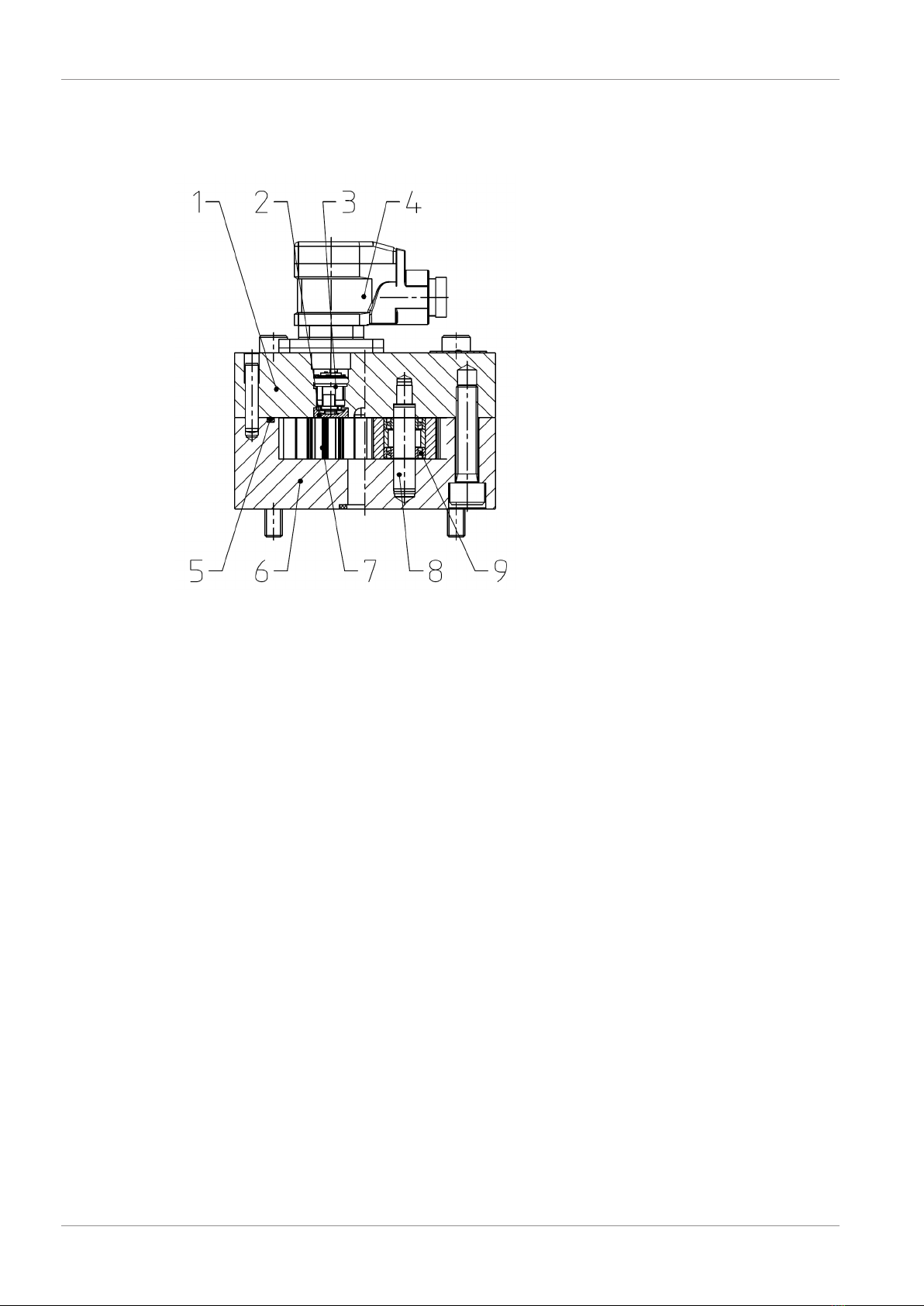

3.2 Basic design........................................................................................................................................................ 10

3.3 Type key............................................................................................................................................................... 11

3.4 Special numbers ............................................................................................................................................... 12

4 Technical data............................................................................................................................. 14

4.1 General................................................................................................................................................................. 14

4.2 Nominal sizes..................................................................................................................................................... 15

4.3 Connection sizes............................................................................................................................................... 15

4.4 Flow resistance ∆p........................................................................................................................................... 17

4.4.1 Ball bearing version ..................................................................................................................... 17

4.4.2 Plain bearing version................................................................................................................... 19

4.5 Operating pressure.......................................................................................................................................... 21

4.6 Permissible temperature range .................................................................................................................. 22

4.7 Material data...................................................................................................................................................... 23

4.8 Weight.................................................................................................................................................................. 23

4.9 Dimensions......................................................................................................................................................... 24

5 Transport and storage ............................................................................................................... 25

5.1 General................................................................................................................................................................. 25

5.2 Transport............................................................................................................................................................. 25

5.3 Storage................................................................................................................................................................. 25

5.4 Storage conditions .......................................................................................................................................... 26

6 Installation .................................................................................................................................. 27

6.1 Safety instructions for installation............................................................................................................. 27

6.2 Mechanical installation .................................................................................................................................. 29

6.2.1 Preparation...................................................................................................................................... 29

6.2.2 Plate connection ........................................................................................................................... 29

6.2.3 pipe connection ............................................................................................................................ 31