1 General

1.1 About the documentation

These operating instructions describe the installation, operation and mainte-

nance of the following device:

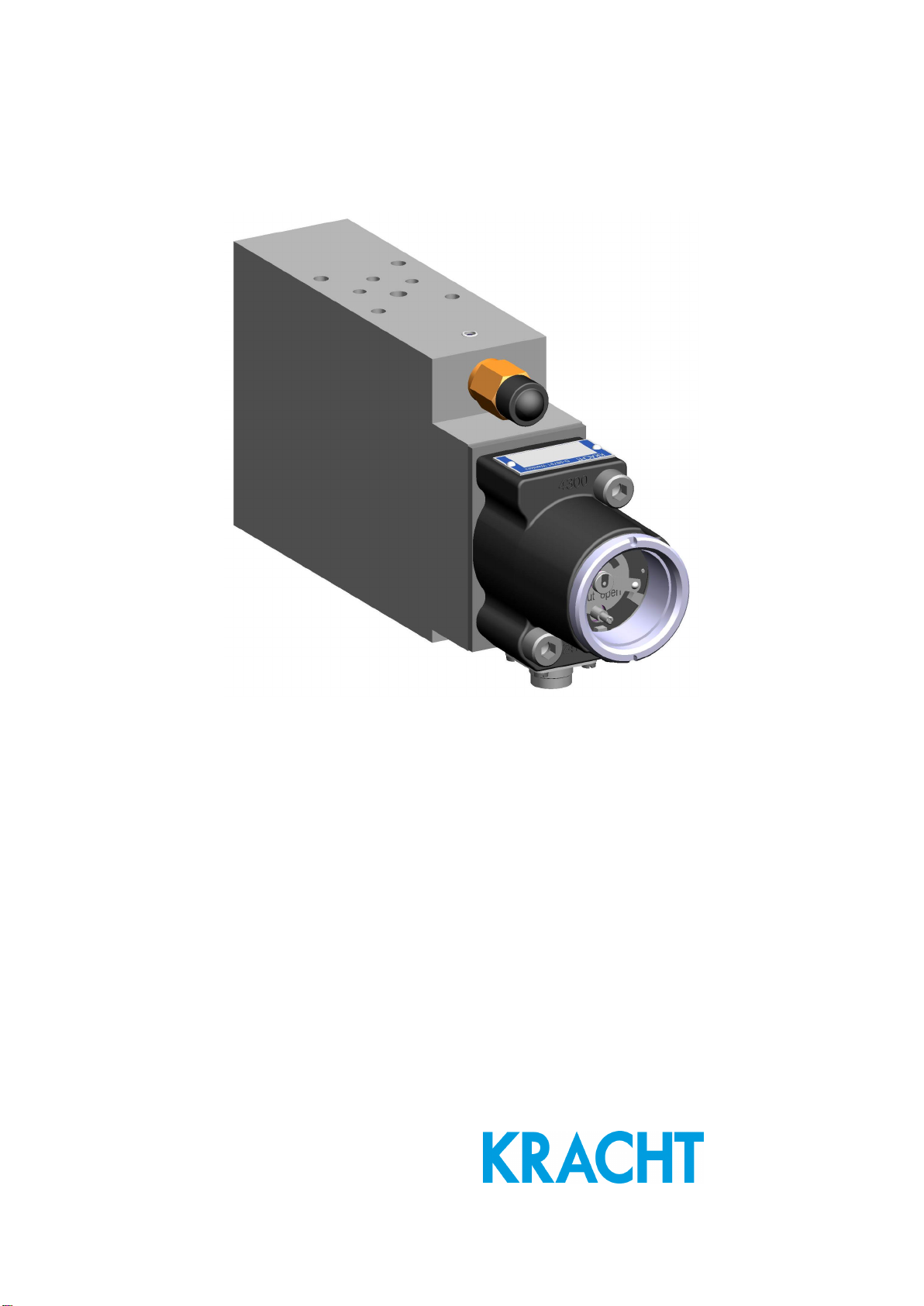

VOLUMEC Valve Position Indicator 02/04

The device is manufactured in different versions. Information about the ver-

sion concerned in the individual case can be found on the device's type plate.

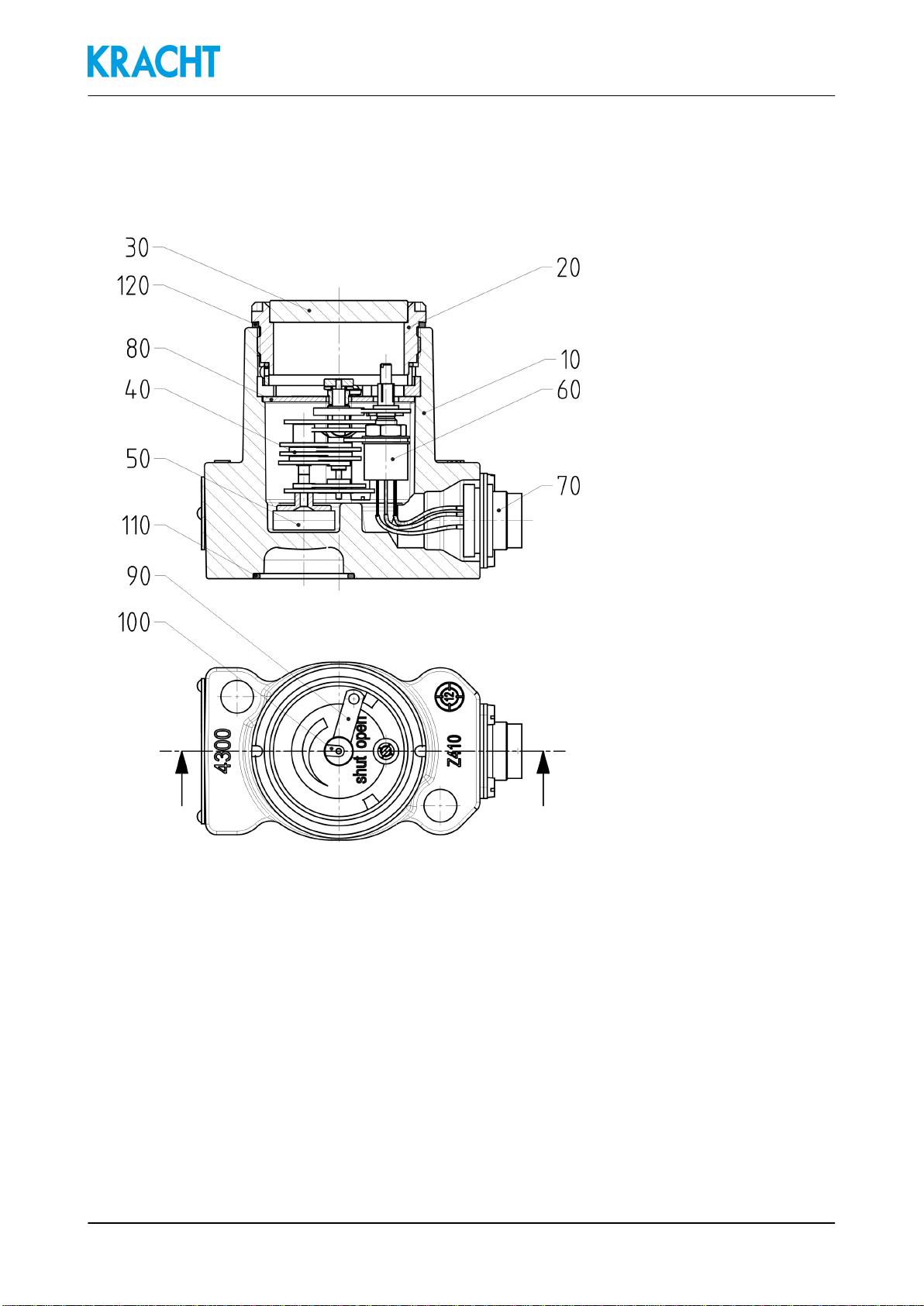

The structure of the type designation and a more detailed description of the

individual series and nominal sizes can be found in the chapter 3 “Device

description” and in the chapter 4 “Technical data”.

If you have any questions about this operating manual, please contact the

manufacturer.

1.2 Manufacturer´s address

KRACHT GmbH

Gewerbestraße 20

DE 58791 Werdohl

phone: +49 2392 935-0

fax: +49 2392 935-209

web: www.kracht.eu

1.3 Intended use

1. The device is used to measure and display the displacement distance of

hydraulic activated ship fittings for ballast, cargo or stripping systems.

The position of the fitting is measured and optically displayed on the de-

vice and output as an analogue signal.

2. The display of the volumetric-recorded valve position can be read visu-

ally onsite or tapped electrically through a potentiometer and/or limit

switch.

3. Comply with the permissible operating data.

4. Comply with the permissible mounting position.

5. The electronic device has been constructed according to the latest tech-

nical standard. Only use it:

○in a perfect technical condition,

VOLUMEC Valve Position Indicator 02/04

42022-07-08 88030390002-03