Kracht GmbH

ii 88046020002

1 General ................................................................................................................................................................4

1.1 About the documentation ....................................................................................................................................................... 4

1.2 Manufacturer address................................................................................................................................................................ 4

1.3 Applicable documents............................................................................................................................................................... 4

1.4 Symbols........................................................................................................................................................................................... 5

2 Safety...................................................................................................................................................................6

2.1 Intended use.................................................................................................................................................................................. 6

2.2 Personnel qualification and training.................................................................................................................................... 6

2.3 Basic safety instructions............................................................................................................................................................ 7

2.4 Fundamental hazards.................................................................................................................................................................7

3 Device description.............................................................................................................................................. 9

3.1 Functional principle .................................................................................................................................................................... 9

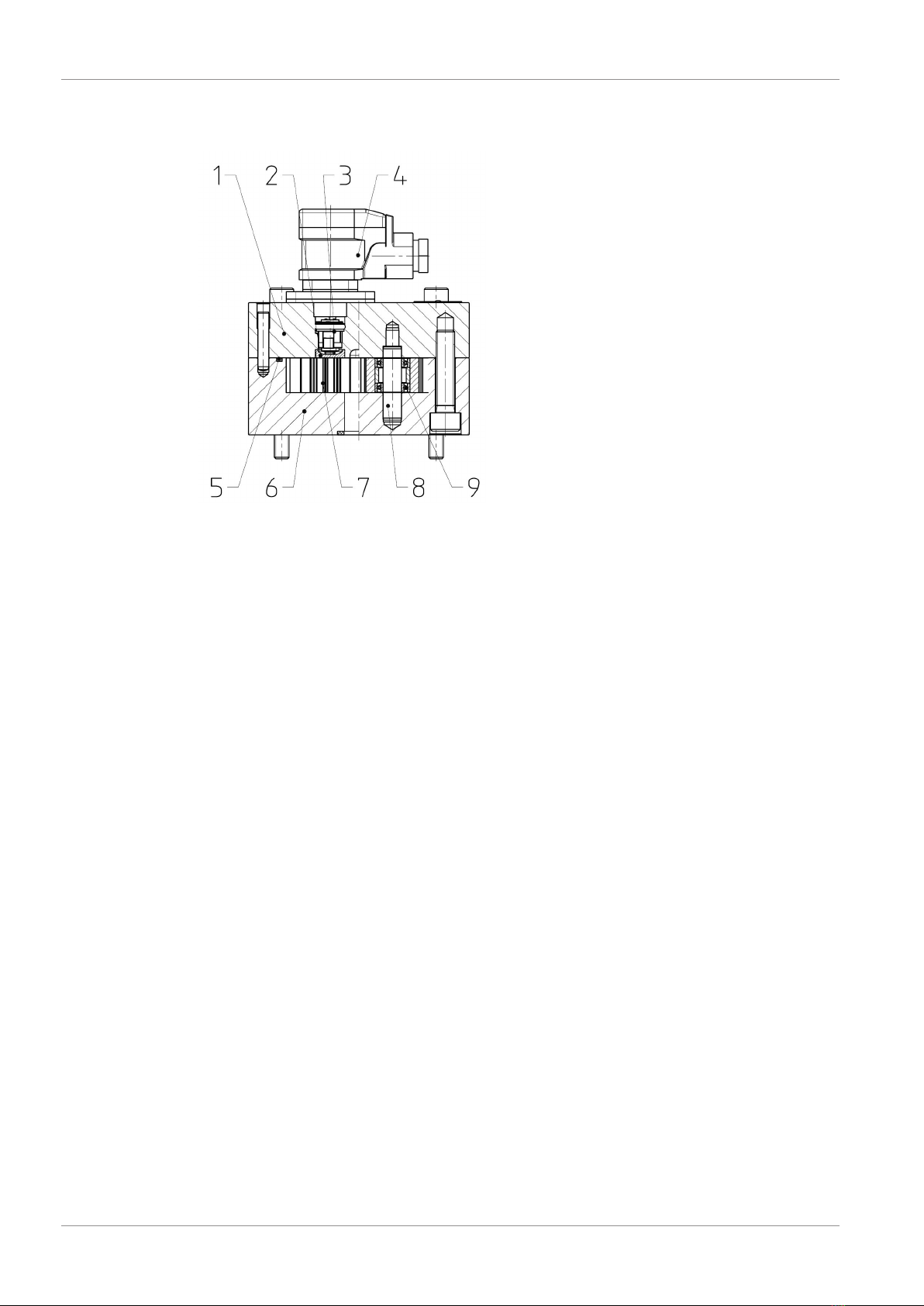

3.2 Basic design.................................................................................................................................................................................10

3.3 Type key ........................................................................................................................................................................................11

4 Technical data...................................................................................................................................................13

4.1 General ..........................................................................................................................................................................................13

4.2 Overview nominal sizes...........................................................................................................................................................14

4.3 Overview connection sizes.....................................................................................................................................................15

4.4 Flow resistance Δp ....................................................................................................................................................................17

4.4.1 Ball bearings..................................................................................................................................................................17

4.4.2 Plain bearings...............................................................................................................................................................20

4.5 Operating pressure...................................................................................................................................................................22

4.6 Permissible temperature range............................................................................................................................................23

4.7 Material data ...............................................................................................................................................................................24

4.8 Weight ...........................................................................................................................................................................................25

4.9 Dimensions ..................................................................................................................................................................................26

5 Transport and storage .....................................................................................................................................27

5.1 General ..........................................................................................................................................................................................27

5.2 Storage ..........................................................................................................................................................................................27

5.3 Storage conditions....................................................................................................................................................................28

6 Installation ........................................................................................................................................................29

6.1 Important notes about explosion protection.................................................................................................................29

6.2 Mechanical installation............................................................................................................................................................30

6.2.1 Preparation....................................................................................................................................................................30

6.2.2 Plate connection ........................................................................................................................................................30

6.2.3 Pipe connection...........................................................................................................................................................32

6.2.4 Rotary encoder ............................................................................................................................................................32

6.3 Electrical connection ................................................................................................................................................................33