2

We would like to congratulate you on your new sweeper KRÄNZLE 1+1.

To ease your introduction to the use of the sweeper, we have provided the

following pages of explanations, tips and hints, which we ask you to read before

using for the first time.

It is our desire that the good characteristics of the KRÄNZLE 1+1 should justify

the confidence you demonstrated to us by making this purchase.

We tried to supply you with an efficient and dependable machine. Prior to

starting-up this machine, read the operating manual carefully. It will inform you in

detail about operation of the unit and provides valuable advice for service and

maintenance.

The KRÄNZLE 1+1 is designed

exclusively for sweeping floors, e.g. in

production facilities, warehouses,

parking sites, and pedestrian areas, for

collecting both, dry an moist matter.

Use in excess of these specifications

will be deemed to be improper use; the

manufacturer cannot be held liable for

consequential damage.

Proper use also includes that

maintenance work is done as specified

by the manufacturer.

As soon as the machine arrives,

please check whether any damage has

occured in transit.

This will be refunded to you if you

have confirmed the damage im-

mediately by the Forwarding agent.

The sweeper ist adjusted for use

on even ground.

Dear customer

Description

Provisions for use............................14

Acceptance for the machine.............14

First operation...............................16

Assembly.........................................16

Attach handlebar.............................16

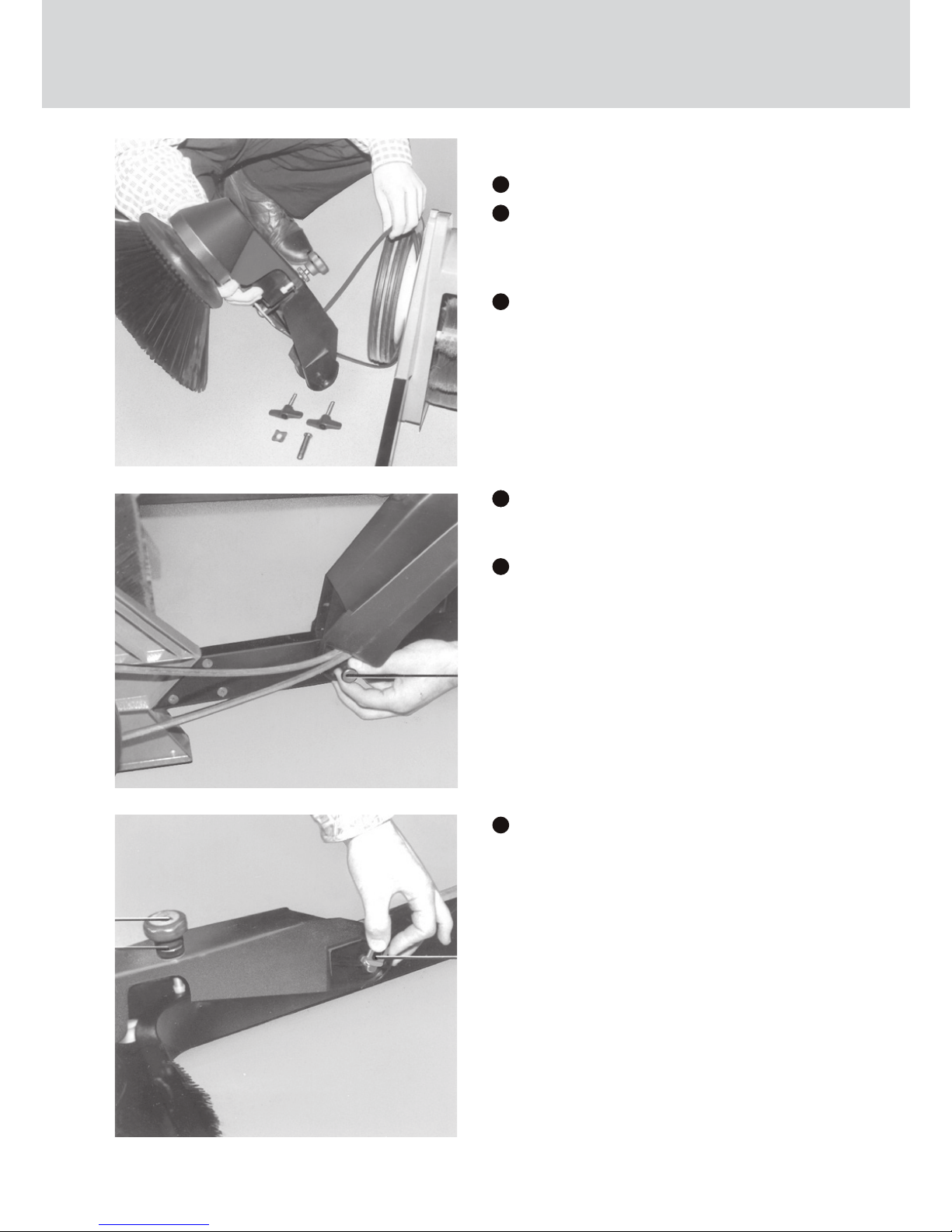

Attach side broom............................17

Operating the KRÄNZLE 1+1.......18

Controls...........................................19

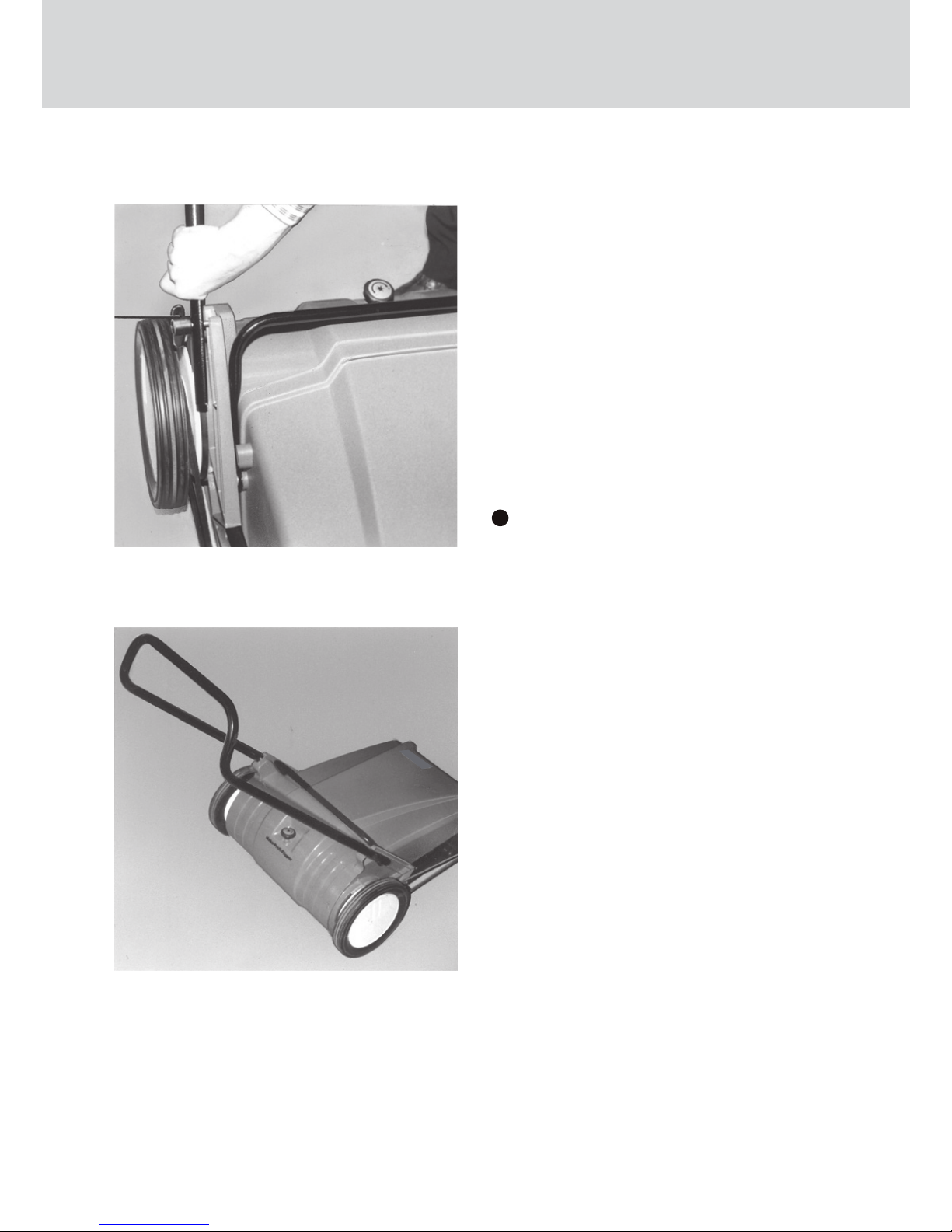

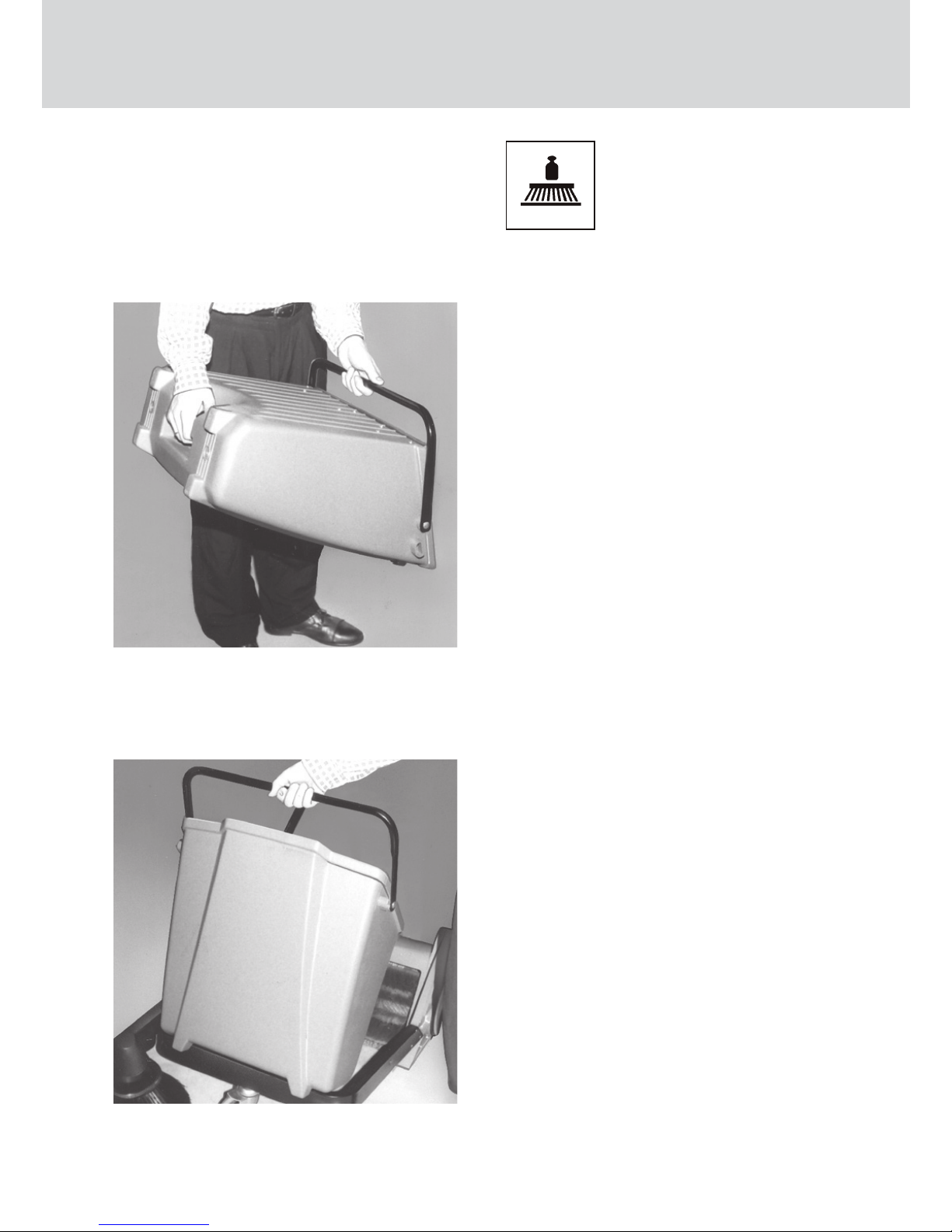

Emptying the dirt hopper..................20

Technical Data...............................15

Insert the dirt hopper........................20

Replacement of main broom............21

Side broom......................................22

Replacement of side broom.............22

Adjust tension of side broom

Vee belt...........................................22

Replacement of side broom

Vee belt...........................................23

Sealing lips......................................23

Greaser track wheels.......................24

Maintenance / Guarantee..............25

Maintenance works.........................25

Intervals..........................................25

Guarantee......................................25

width w/o side broom

width with side broom

height with handlebar, handlebar high position

height with handlebar, handlebar low position

height with folded handlebar

lenght with folded handlebar with side broom

lenght w/o side broom, handlebar high position

lenght w/o side broom, handlebar low position

lenght with side broom, handlebar high position

lenght with side broom, handlebar low position

weight (operating, incl. side broom)

drive wheels (dia./width)

swept width w/o side broom

swept width with side broom

broom roller dia.

broom roller width

min. dia. of roller broom

broom speed at 4 km/h (2.5 mph)

side broom (Polyester), dia.

side broom speed at 4 km/h (2.5 mph)

side broom drive (Vee belt)

dirt hopper (40 litres capacity)

surfacing rating (theoretic) at 4 km/h with side broom

720 (28.35)

790 (31.10)

1060 (41.7)

900 (35.4)

390 (15.35)

1,030 (40.5)

1,080 (42.5)

1,260 (49,6)

1,330 (52.4)

1,510 (59,4)

25 (55)

280 x 40

(11.02 x 1.57)

480 (18.9)

670 (26.38)

250 (9.84)

480 (18.9)

180 (7.09)

250

325 (12.8)

85

8 x 1765 5

25 - 28 usable

2,680

mm (”)

mm (”)

mm (”)

mm (”)

mm (”)

mm (”)

mm (”)

mm (”)

mm (”)

mm (”)

kg (lbs)

mm

(”)

mm (”)

mm (”)

mm (”)

mm (”)

mm (”)

rpm

mm (”)

rpm

mm

l2

m /h

Technical Data

Table of Contents

Description GB

15

_

+