Page 2 of 20

TABLE of CONTENTS

INTRODUCTION .......................................................................................................................................................................... 3

SERIAL NUMBER INFORMATION ............................................................................................................................................. 3

RECEIVING AND INSPECTING THE EQUIPMENT ................................................................................................................. 4

APPLIANCE SAFETY .................................................................................................................................................................... 4

IMPORTANT SAFEGUARDS ........................................................................................................................................................ 5

Electrical Connection ................................................................................................................................................................... 6

Refrigerant Disposal .................................................................................................................................................................... 6

Appliance Disposal ...................................................................................................................................................................... 6

APPLIANCE INSTALLATION ...................................................................................................................................................... 7

Remove Packaging Materials ....................................................................................................................................................... 7

Location Requirements ................................................................................................................................................................ 7

Inside cabinet: .............................................................................................................................................................................. 7

Outside cabinet: ............................................................................................................................................................................ 7

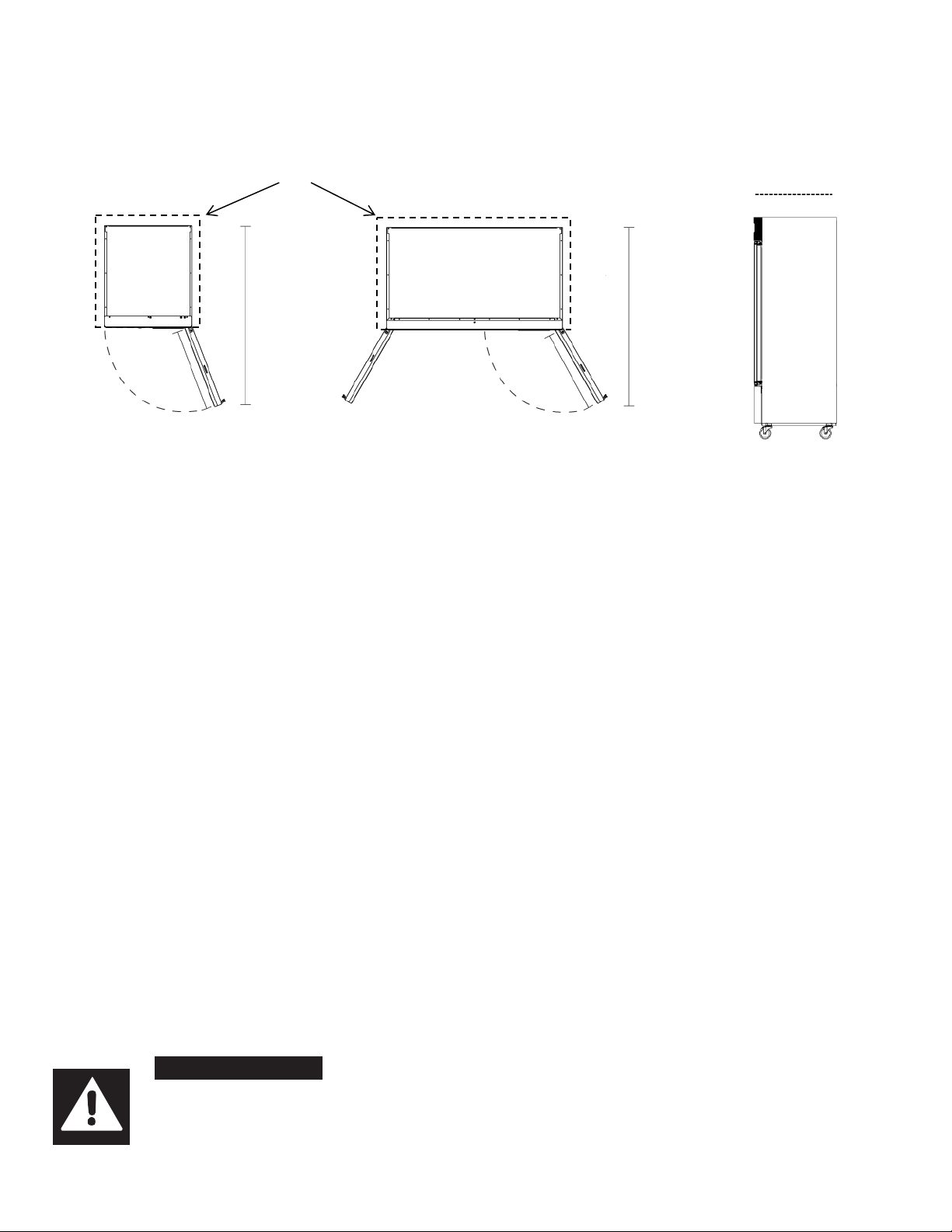

Installation Clearance ................................................................................................................................................................... 8

Leveling ....................................................................................................................................................................................... 8

Stabilizing .................................................................................................................................................................................... 8

Electrical Connection ................................................................................................................................................................... 8

OPERATION ................................................................................................................................................................................... 9

Refrigerated cycle ........................................................................................................................................................................ 9

Power Switch: .............................................................................................................................................................................. 9

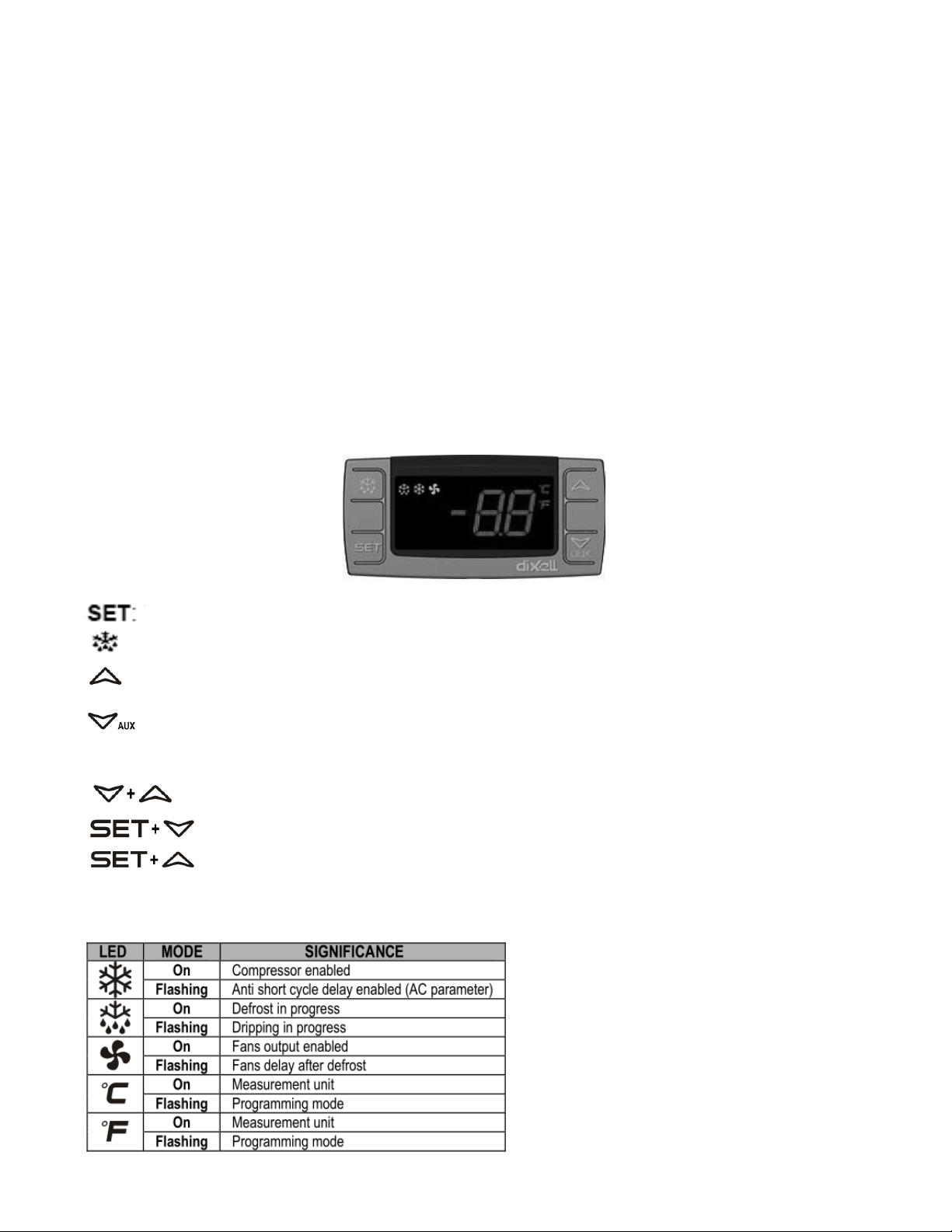

SOLID-STATE THERMOSTAT DE SC RI PT IO NS ......................................................................................................................... 9

1. FRONT PANEL COMMANDS. .............................................................................................................................................. 9

2. MAIN FUNCTIONS .............................................................................................................................................................. 10

3. ALARM SIGNALLING ........................................................................................................................................................ 10

TIPS FOR PROPER OPERATION, CLEANING AND MAINTENANCE ................................................................................. 11

CLEANING AND MAINTENANCE ........................................................................................................................................... 12

Exterior and Interior Cleaning of Appliances ............................................................................................................................ 12

Cleaning the Condenser Coil ..................................................................................................................................................... 12

Stainless Steel Care and Cleaning .............................................................................................................................................. 13

Gasket Maintenance ................................................................................................................................................................... 13

Doors/Hinges ............................................................................................................................................................................. 13

Drain Maintenance ..................................................................................................................................................................... 13

TROUBLESHOOTING GUIDE ................................................................................................................................................. 14

TROUBLESHOOTING CHART .................................................................................................................................................. 14

SERVICE AND TROUBLESHOOTING TIPS ............................................................................................................................. 15

DIMENSIONS AND TECHNICAL INFORMATION .................................................................................................................. 16

COMPONENT INFORMATION ................................................................................................................................................ 17

REFRIGERATION DIAGRAM .................................................................................................................................................... 17

WIRING DIAGRAMS .................................................................................................................................................................. 18

PARTS ............................................................................................................................................................................................ 19