Page 2of 18

TABLE of CONTENTS

SERIAL NUMBER INFORMATION .............................................................................................................................................3!

APPLIANCE SAFETY ....................................................................................................................................................................4!

IMPORTANT SAFEGUARDS........................................................................................................................................................5!

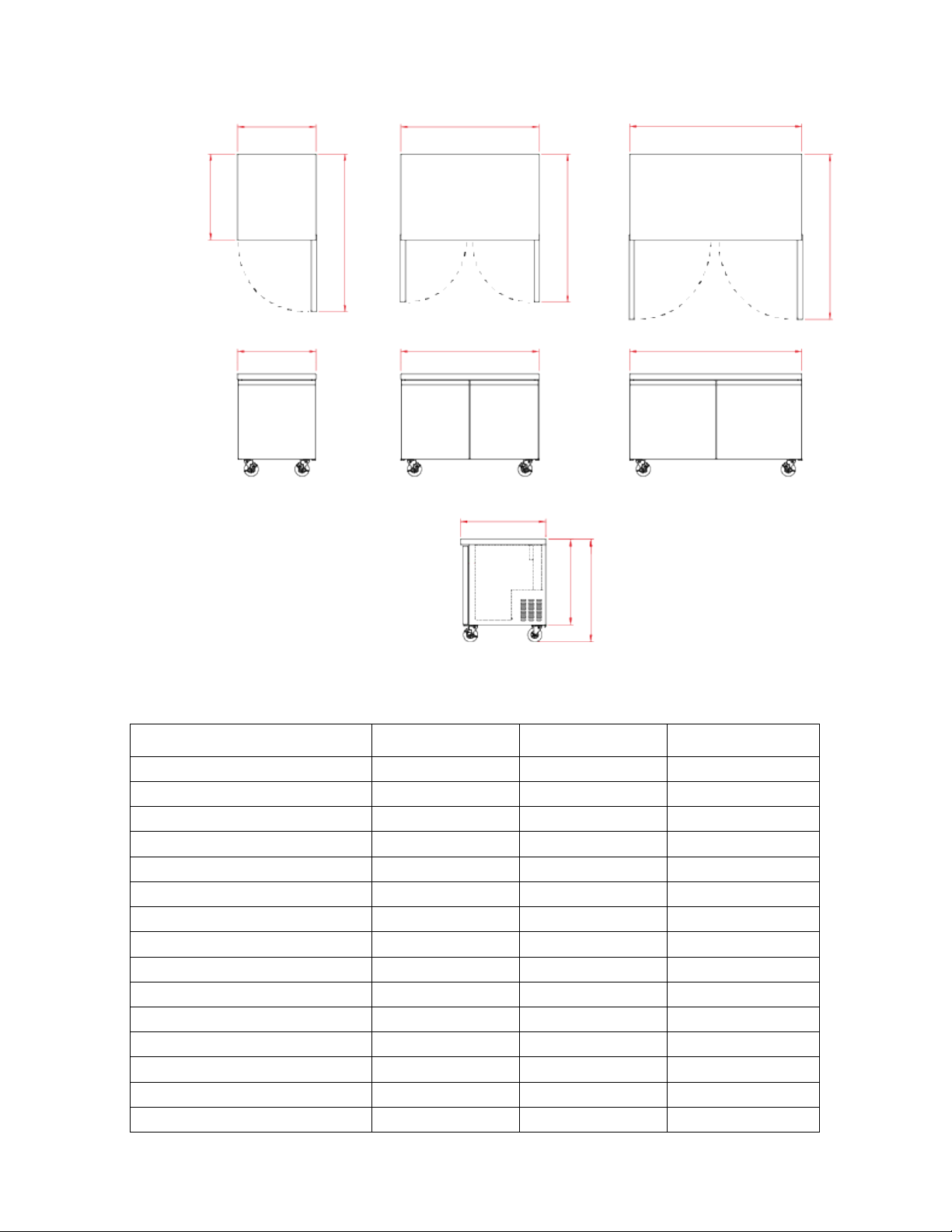

DIMENSIONS..................................................................................................................................................................................7!

TECHNICAL INFORMATION.......................................................................................................................................................7!

RECEIVING AND INSPECTING THE EQUIPMENT..................................................................................................................8!

INTRODUCTION

...........................................................................................................................................................................8!

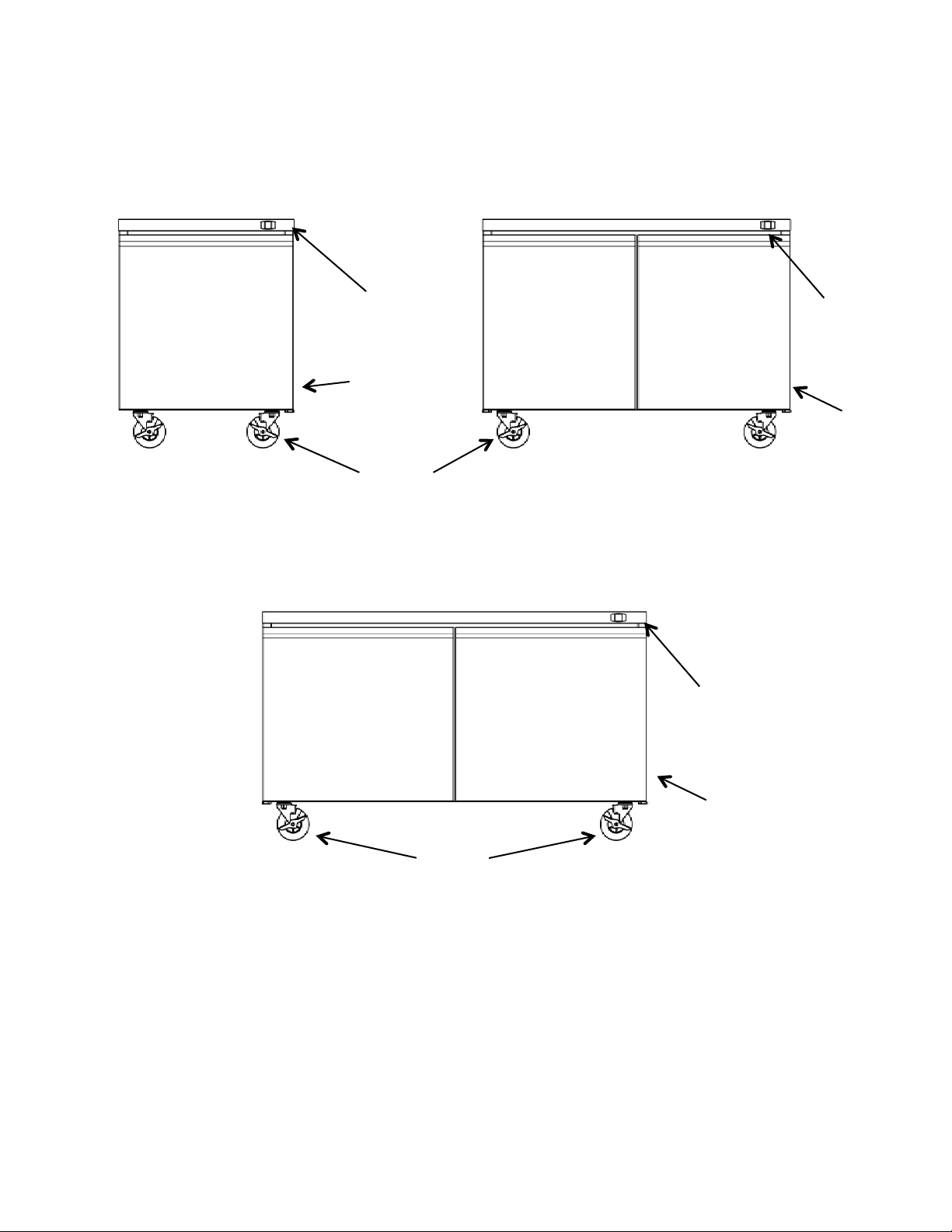

COMPONENT INFORMATION

..................................................................................................................................................9!

APPLIANCE INSTALLATION ....................................................................................................................................................10!

Remove Packaging Materials .....................................................................................................................................................10!

Location Requirements...............................................................................................................................................................10!

Inside cabinet: .............................................................................................................................................................................10!

Outside cabinet: ..........................................................................................................................................................................10!

Installation Clearance .................................................................................................................................................................11!

Leveling ......................................................................................................................................................................................11!

Stabilizing ...................................................................................................................................................................................11!

Electrical Connection..................................................................................................................................................................11!

OPERATION..................................................................................................................................................................................12!

Refrigerated cycle.......................................................................................................................................................................12!

Power Switch:.............................................................................................................................................................................12!

SOLID-STATE THERMOSTAT DESCRIPTIONS......................................................................................................................12!

1. FRONT PANEL COMMANDS.............................................................................................................................................12!

2. MAIN FUNCTIONS ..............................................................................................................................................................13!

3. ALARM SIGNALLING.........................................................................................................................................................13!

CLEANING AND MAINTENANCE............................................................................................................................................14!

Exterior and Interior Cleaning of Appliances.............................................................................................................................14!

Cleaning the Condenser Coil ......................................................................................................................................................14!

Stainless Steel Care and Cleaning ..............................................................................................................................................15!

Gasket Maintenance....................................................................................................................................................................15!

Doors/Hinges ..............................................................................................................................................................................15!

Drain Maintenance......................................................................................................................................................................15!

TROUBLESHOOTING GUIDE

.................................................................................................................................................16!

TROUBLESHOOTING .................................................................................................................................................................16!

WIRING DIAGRAMS ...................................................................................................................................................................17!