Dok-236-GB-6bar.doc

1 USE FOR INTENDED PURPOSE

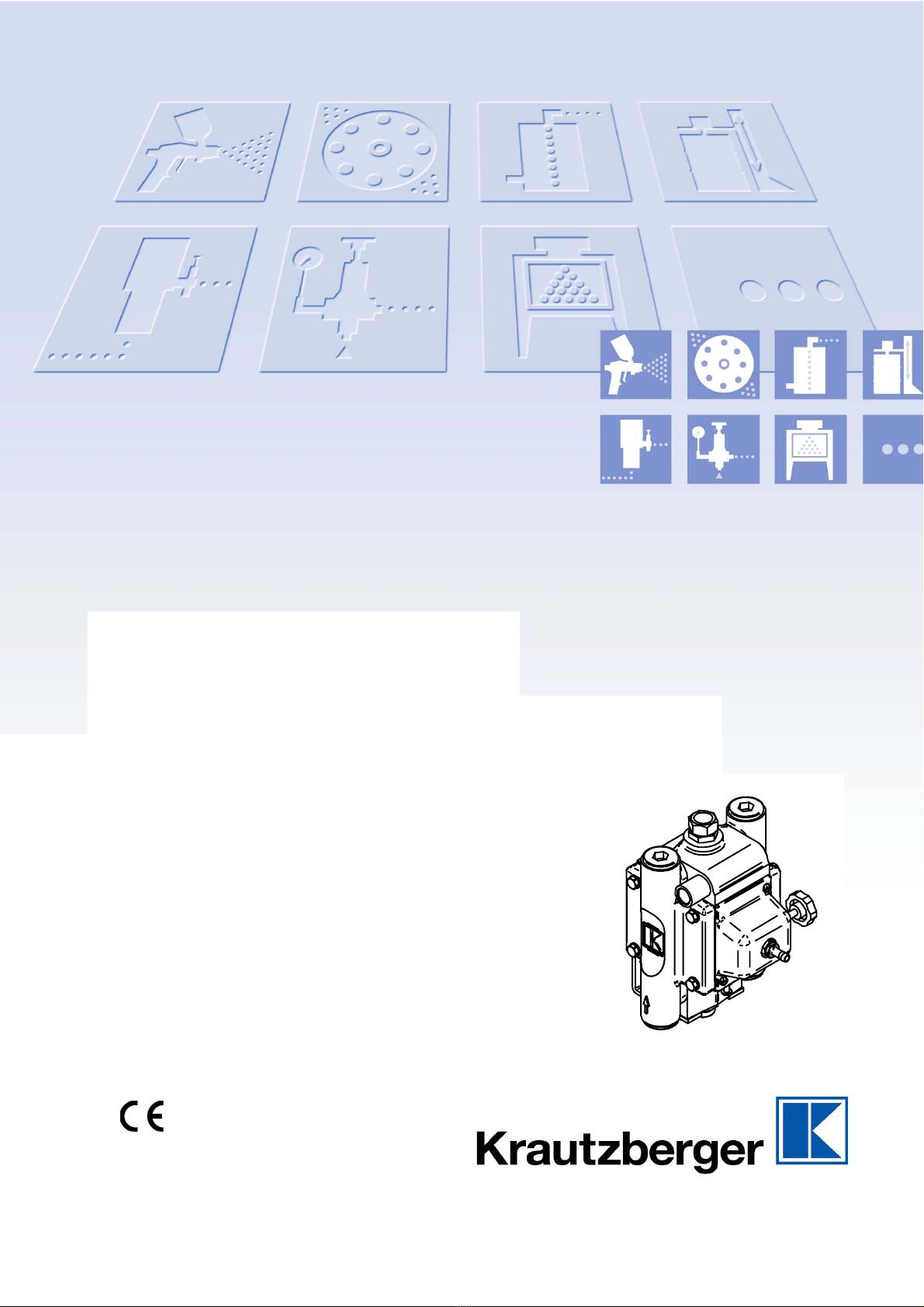

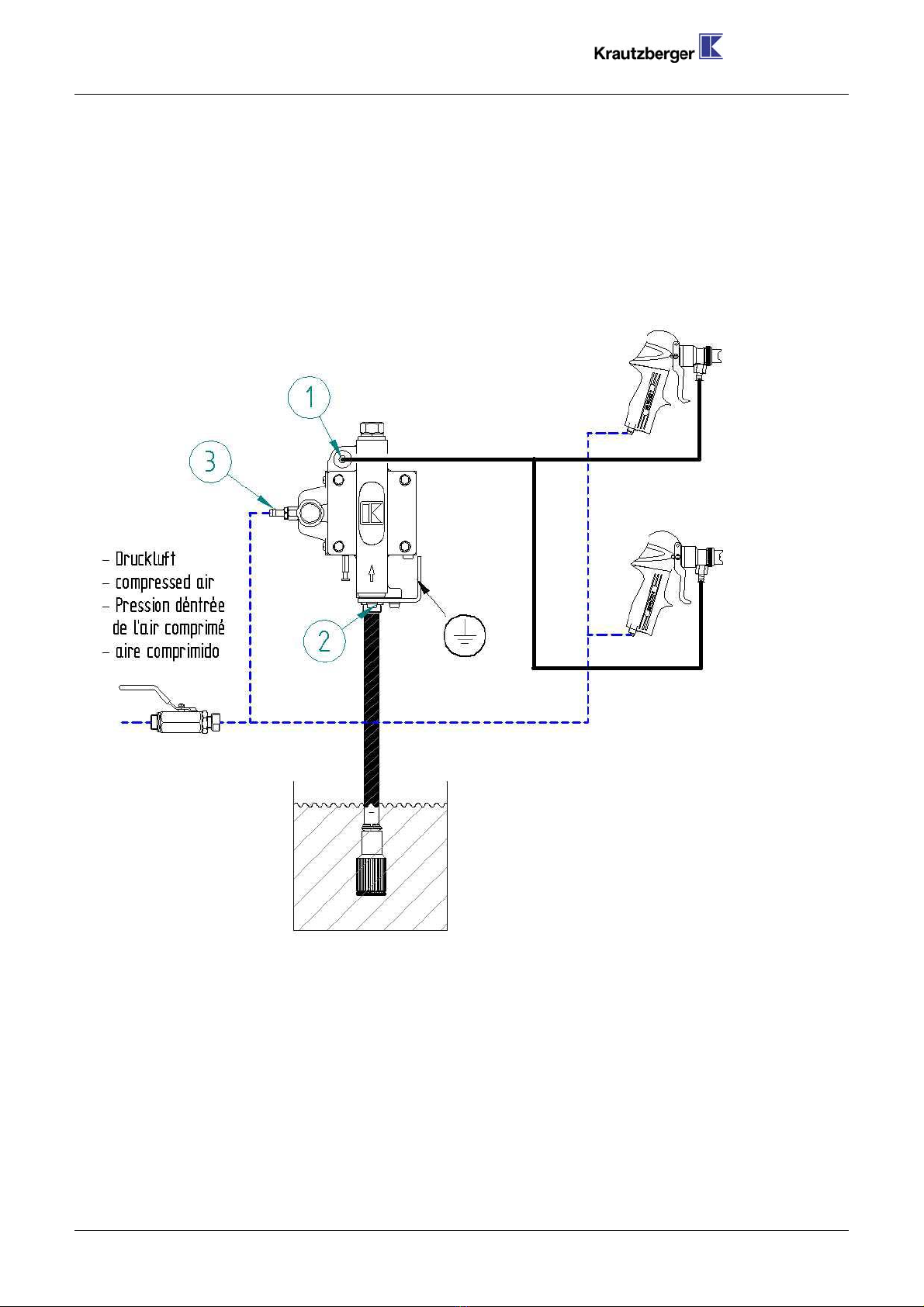

The diaphragm pump MP-400 is a pump driven by compressed air and is designed exclusively for

the:

conveying of liquid and low-viscosity coating material from pressureless storage containers

supply of material to spray guns, automatic spray guns, metering devices and similar

It is mainly used for painting and coating operations.

The diaphragm pump MP-400 complies with equipment category II 2G (ATEX 100a) and may be

operated in potentially explosive areas in "Zone 1".

When used in potentially explosive areas, the pump must be operated with a run-dry protection device

(e.g. filling level probe in the material container with auto pump switchoff feature)!

In addition, the diaphragms must be regularly checked for wear during safety inspections.

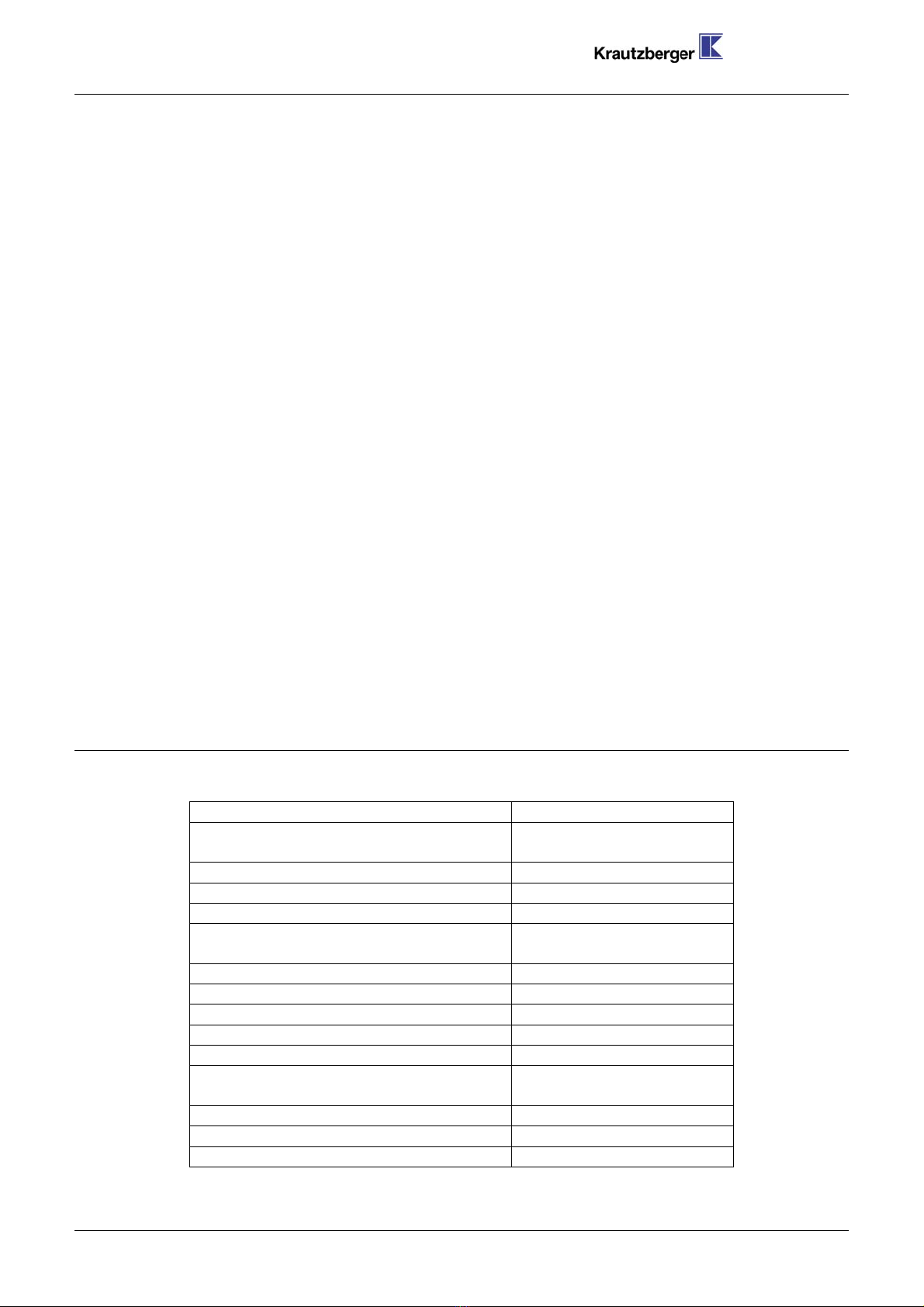

Material conveying properties

Material Suitability

Paints (containing solvents) good

Water-based paints, dispersion paints, Latex,

wood preservative good

Water good

Oils, fuel oil, diesel oil good

Emulsions, soaps, detergents good

Alcohol, glazing agents with qualifications

Lime slurry with qualifications

Cellulose and fibrous materials unsuitable

Paste Sludge, mash, paste unsuitable

In case of doubt, ask about the suitability of non-listed materials. In special cases,

we conduct trials to determine suitability.

2 GENERAL SAFETY NOTES

Diaphragm pumps may only be used in line with the operating parameters

(pressure, temperature etc.) specified under “Technical data”!

The operator must check the compatibility of the pump materials with the

coating substance to be used. To ensure compatibility, refer to the safety data

sheet supplied by the manufacturer of the coating substance!

All work connected with installation and maintenance must be performed by

suitably qualified personnel. Always use original parts when replacing worn or

damaged parts.

Each time before you start working, check the material and compressed air

connections for firm seat and damage! Loose, pressurised hoses may cause

accidents due to whiplash-like movement and the discharge of fluids.

4