Table of contents

1 Information about the operating manual.......................................................................... 5

2 Function and identification................................................................................................ 6

2.1 Function....................................................................................................................... 6

2.2 Identification................................................................................................................. 6

3 Safety and responsibility................................................................................................... 8

3.1 Symbols in this manual................................................................................................ 8

3.2 Personnel requirements............................................................................................... 9

3.3 Personal safety equipment and clothing.................................................................... 10

3.4 Responsibility of the owner........................................................................................ 11

3.5 Intended use.............................................................................................................. 12

3.6 General safety instructions........................................................................................ 14

3.7 Residual risks............................................................................................................ 15

3.8 Course of action in an emergency............................................................................. 15

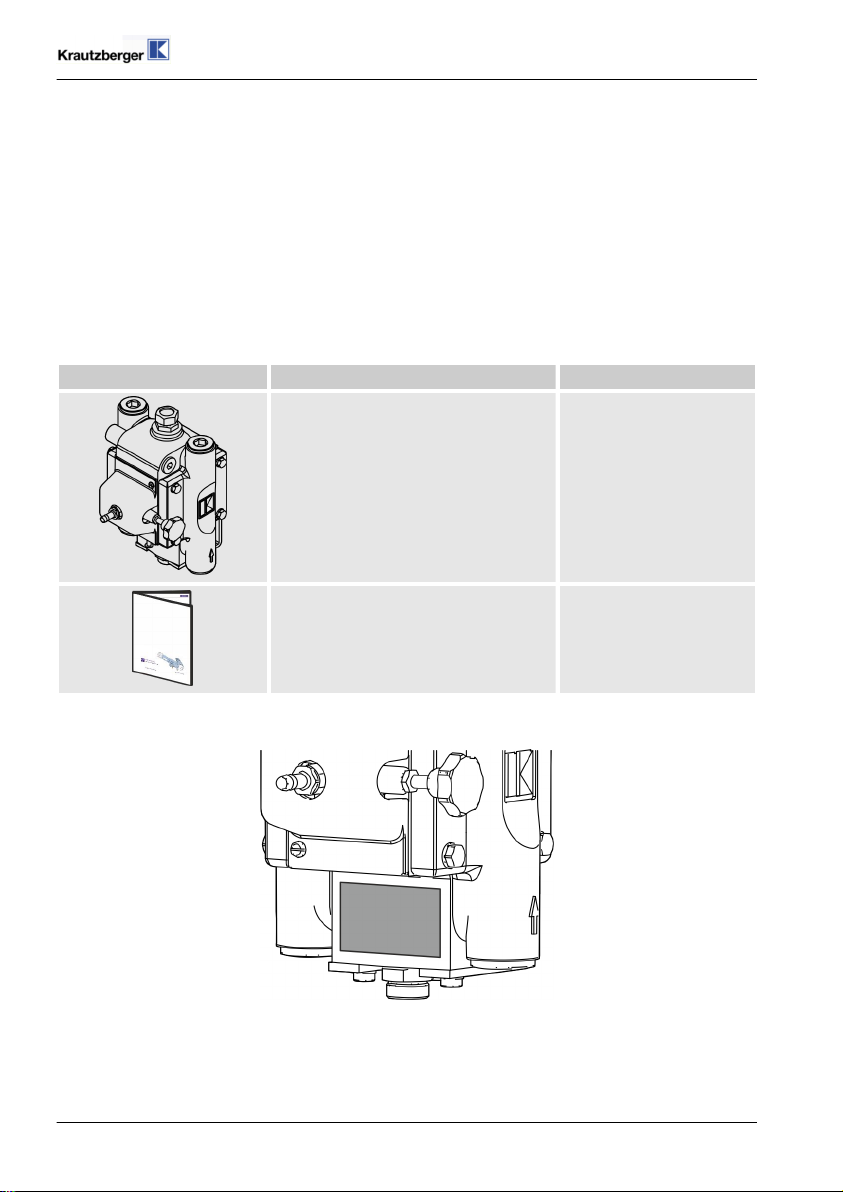

4 Transport, delivery condition, storage, and packaging................................................ 16

4.1 Transport................................................................................................................... 16

4.2 Delivery condition...................................................................................................... 16

4.3 Storage...................................................................................................................... 16

4.4 Packaging.................................................................................................................. 16

5 Overview and dimensions............................................................................................... 17

5.1 Menu.......................................................................................................................... 17

5.2 Dimensions................................................................................................................ 18

6 Installation and disassembly........................................................................................... 19

6.1 Safety......................................................................................................................... 19

6.2 General installation information................................................................................. 19

6.3 Installing the diaphragm pump................................................................................... 20

6.4 Connecting the diaphragm pump............................................................................... 22

6.5 Dismantling the diaphragm pump.............................................................................. 24

7 Start-up.............................................................................................................................. 27

7.1 Safety instructions..................................................................................................... 27

7.2 General information about the start-up...................................................................... 28

7.3 Start-up...................................................................................................................... 29

7.4 Shut-down.................................................................................................................. 29

7.4.1 Temporary shut-down............................................................................................. 29

7.4.2 Long-term shut-down.............................................................................................. 30

8 Maintenance...................................................................................................................... 31

8.1 Safety......................................................................................................................... 31

8.2 General maintenance information.............................................................................. 32

Diaphragm pump MP-400 ENGLISH

Article No. 200-0102

GB–3