KREMLIN REXSON Page 1 Manual : 573.191.112

INSTRUCTION MANUAL

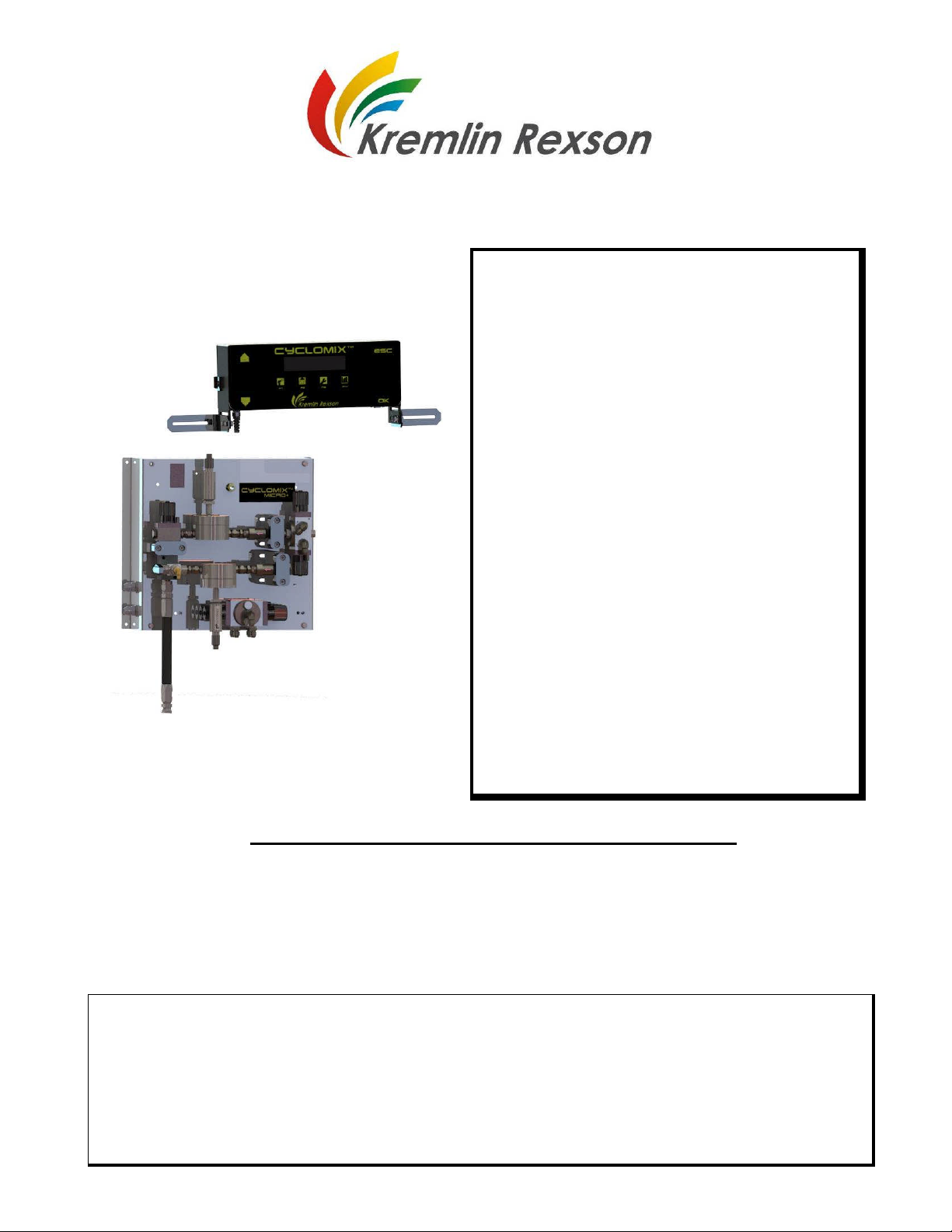

CYCLOMIXTM MICRO, MICRO + & MICRO + PH

MIXING MACHINE

TABLE OF CONTENTS

1. GENERAL SAFETY INSTRUCTIONS ......................................................................................................... 3

INSTALLATION REQUIREMENTS ............................................................................................ 3

EQUIPMENT REQUIREMENTS................................................................................................. 3

MAINTENANCE REQUIREMENTS............................................................................................ 4

ENVIRONMENT.......................................................................................................................... 5

2. DESCRIPTION ............................................................................................................................................. 5

3. OPERATING PRINCIPLE ............................................................................................................................ 7

4. TECHNICAL FEATURES............................................................................................................................. 8

5. INSTALLATION ......................................................................................................................................... 10

DESCRIPTION OF THE LABEL MARKINGS........................................................................... 10

INSTALLATION DIAGRAM....................................................................................................... 11

IMPLANTATION ....................................................................................................................... 12

CONNECTION OF THE CONTROL BAY AND OF THE FLUID PART.................................... 14

6. OPERATING .............................................................................................................................................. 15

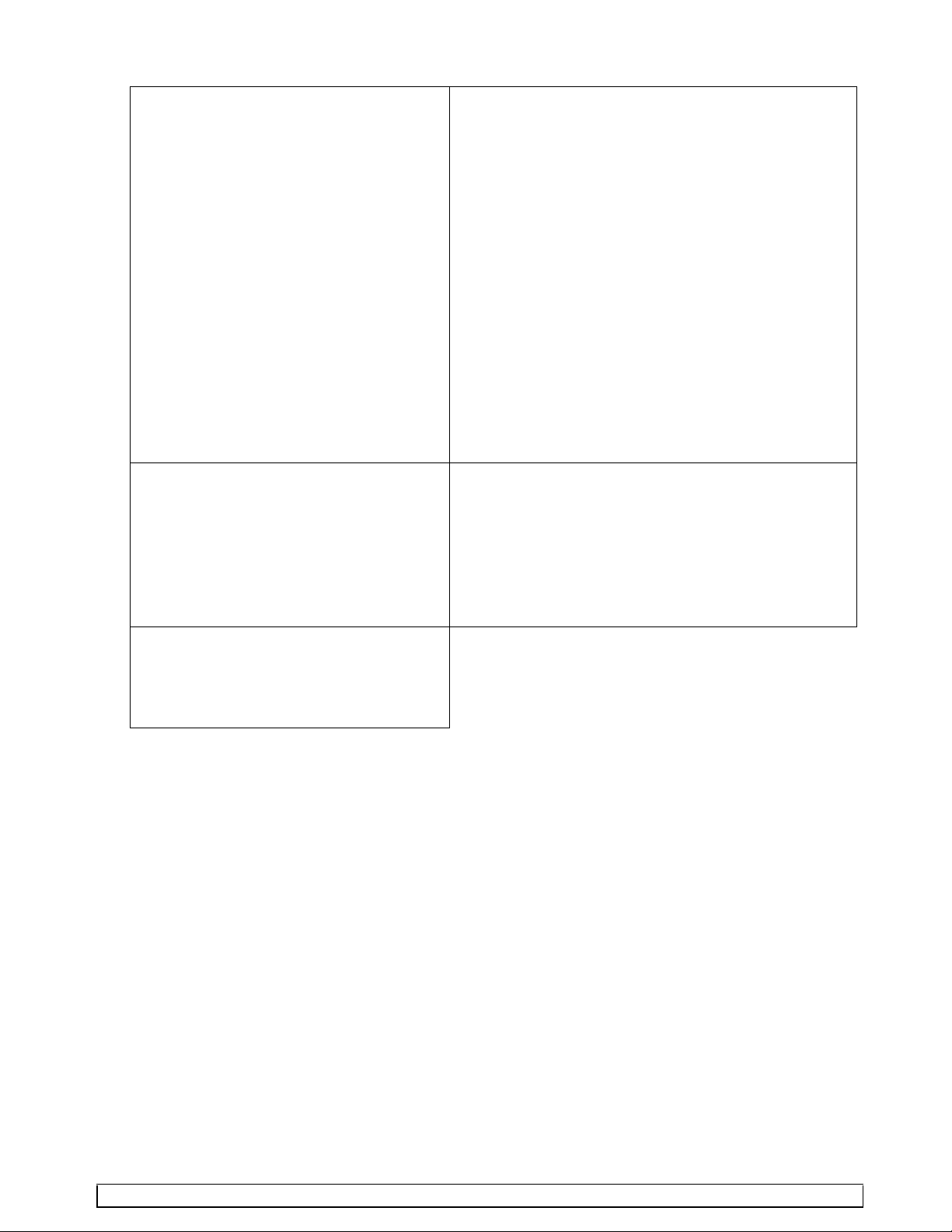

DRIVING FROM THE MACHINE.............................................................................................. 15

SWITCHING ON THE MACHINE ............................................................................................. 15

7. FIRST SWITCHING ON ............................................................................................................................. 16

8. FIRST PLACING INTO OPERATION......................................................................................................... 18

FLUSHING OF THE PUMPS AND OF THE MACHINE INTO SOLVENT................................ 18

START-UP OF THE MACHINE ................................................................................................ 18

9. APPLICATION PROGRAMMING (F3)....................................................................................................... 19

PASSWORD ............................................................................................................................. 19

PROCEDURE TO GET THE VERSION NUMBER OF THE ELECTRONIC CARD................. 19

PARAMETERS FOR MACHINE WITHOUT CATALYST FLUSHING ...................................... 20

PARAMETERS FOR MACHINE WITH CATALYST FLUSHING.............................................. 21

10. PRODUCTION (F1).................................................................................................................................... 23

PROPORTIONING TEST ......................................................................................................... 24

11. FLUSHING (F2).......................................................................................................................................... 24

12. CONSUMPTIONS / PRINT (F4) ................................................................................................................. 26

13. DOWNLOADING DATA FROM CYCLOMIX MICRO TO A COMPUTER.................................................. 27

14. INDICATIONS GIVEN BY THE LEDS........................................................................................................ 31

15. MAINTENANCE ......................................................................................................................................... 31

TROUBLESHOOTING.............................................................................................................. 33

DIAGNOSTICS ......................................................................................................................... 34

16. DISASSEMBLY - REASSEMBLY.............................................................................................................. 36

MIXER....................................................................................................................................... 36

FLOWMETER ........................................................................................................................... 36

PILOTED VALVES (FLUID VALVES AND TEST VALVES) ..................................................... 37