KREMLIN Page 5 Manual : 573.024.212

FILLING VALVE

Piston (1) removal : refer to chapter "PISTON".

Unscrew rod (5) from the motor shaft (25).

In case of wear, change the valve (8) and the seal (18).

ÂCaution !

When reinstalling, rod (5) must be glued into motor-shaft with loctite adhesive.

BELLOWS (20)

If material leaks under the base of the air motor, at the leakage indicators, bellows must be changed.

Proceed as previously indicated when filling valve is removed.

Remove the suction body (2) by unscrewing the 4 fastening screws (21).

The bellows is released when suction body is taken out.

To reinstall bellows, fit its lower part (small diameter) into skirt (9).

Slip bellows on shaft (25). Screw rod (5) - with its seal (18) and filling valve (8). (The whole must be

slightly glued with loctite adhesive).

Hold rod (5) by means of the flat-parts of motor-shaft (25).

Insert the suction body after pushing the motor-shaft upwards. Fit the 4 screws (21) and gradually

tighten them in criss-cross manner. Torque screws (21).

Reinstall the other parts as previously described.

AIR MOTOR REVERSING BLOCK (DOC. 573.174.050)

Disassemble the cover (51) by removing the 2 CHc screws (52).

Dissociate female yoke (54) from reversing block lever (55).

Dismount the reversing block by removing screws (50 and 43).

Reinstall the new reversing block in the reverse order of the disassembly

sequence.

ÂCAUTION : The number of spirals must equally be distributed on

each fastening parts in order to get the above dimension.

Before reassembling the different components :

-Clean the parts with white spirit or with the appropriate cleaning solvent.

-Install new seals if necessary, after having lubricated them with PTFE grease.

-Lubricate the piston and the inside of the cylinder to prevent from damaging the seals.

-Install new parts if necessary.

DEGREES OF WEAR

The wetted parts in contact with the material are subject to wear with time. It depends, of course, on

the rates and duration of pump operating; also on the material handled.

Under normal operating and servicing conditions, with standard filled material not including foreign

matters of chemically agressive, the average working life can be estimated as :

-1 million strokes for the tightness seals.

-10 millions strokes for the bellows .

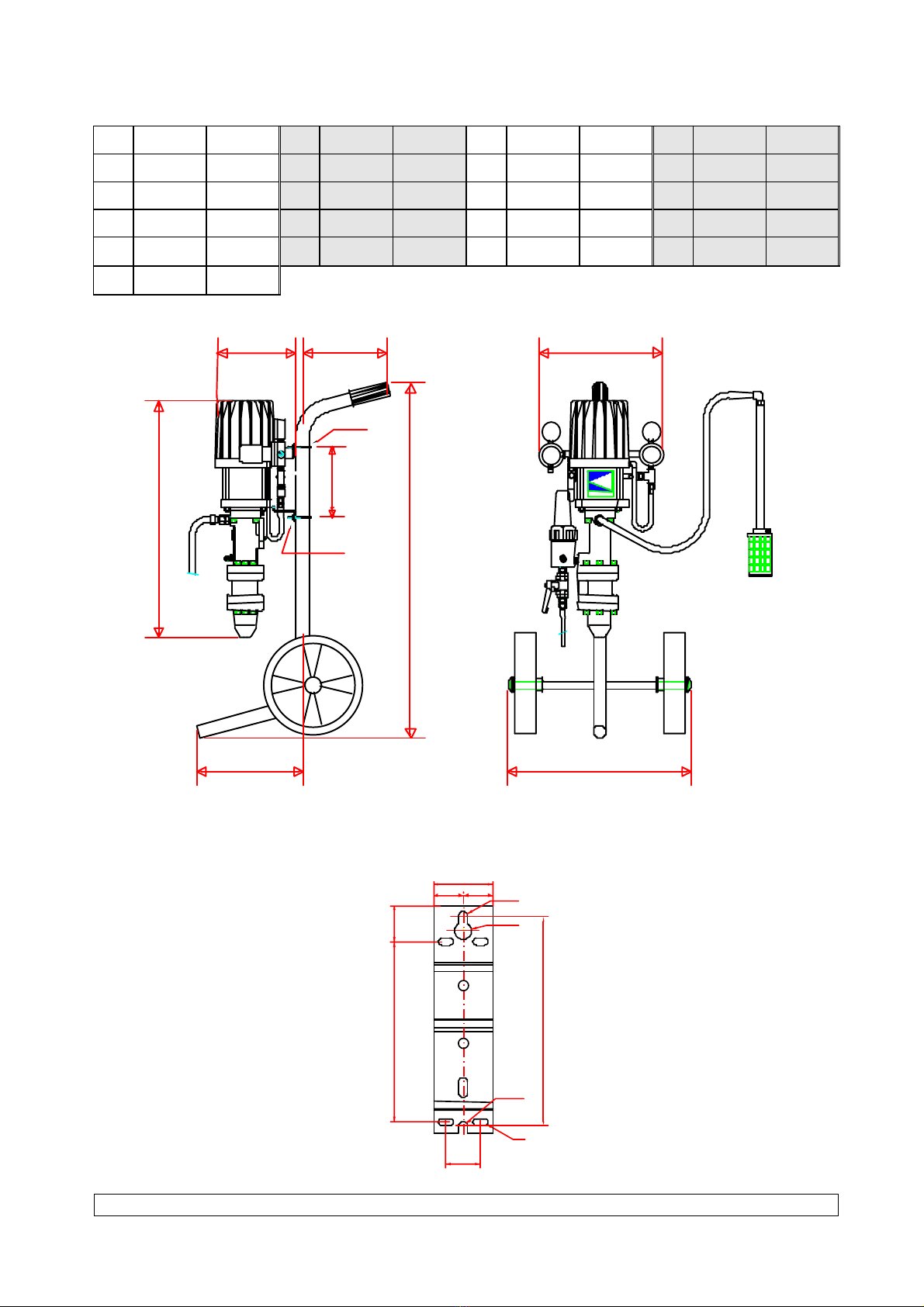

31.85 mm ±0.5