1 Safety

1.1 Possible Dangers operating the Machine

The Steel Cutter Model RC has been manufactured according to the latest

technical knowledge and is operationally reliable. A functional and safety test

has been carried out. In spite of this fact, it is possible that certain dangers are

imminent if the cutter is not being operated by trained personnel or at least

personnel who has received relevant instruction on the operation. The same

goes for using the steel cutter if it is being operated in an inappropriate manner

and if it is being used for purposes which it has not been destined for.

ATTENTION: If the content of this instruction manual is not being

observed, the operator or any bystanders are running

the risk of getting injured!

1.2 Safety Instructions

During the cutting of steel, especially when cutting pieces under 20 cm in

length, there is always the risk of flying steel fragments. This can lead to

serious injuries to any bystanders who are within the danger area. This danger

area is a considerable area located within the circumference where the

operating is taking place. Operate the steel cutter only if there are no

bystanders within the danger area.

•Always wear safety goggles or a full-face shield when cutting.

•Always wear proper working clothes. It is not appropriate to wear wide

clothes, because it might get caught between the cutter blades.

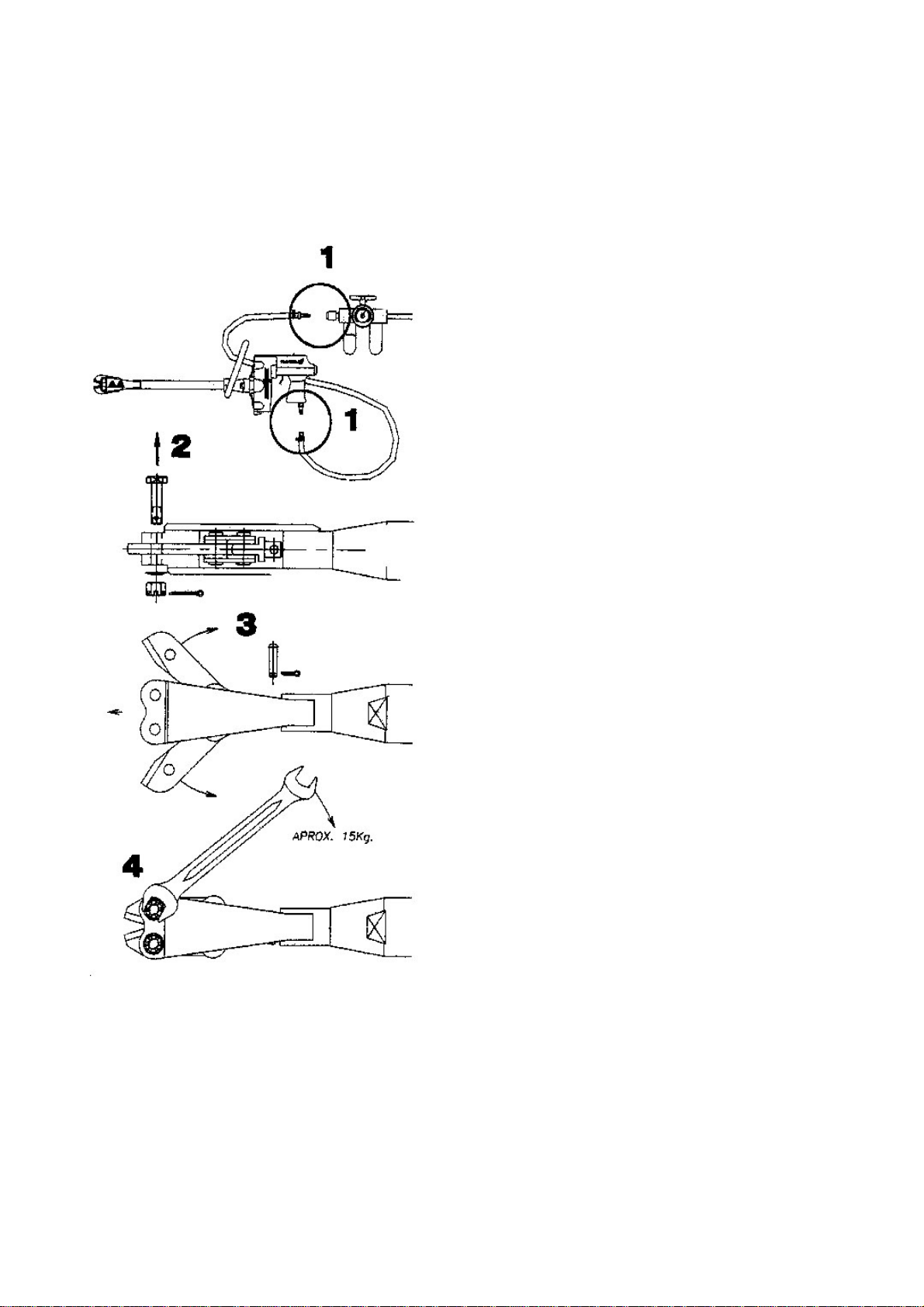

•Always hold the cutter with both hands at the corresponding handles.

Keep your fingers away from the cutter blades.

•Before cutting, the steel bar must rest fully within the cutter blades.

•Avoid any unintentional operation of the cutter. Never carry the cutter

with your finger being at the switch.

•To prevent an electrical shock, never cut any cables which are current-

carrying.

•If you are not using the cutter head or in case you are replacing it,

always disconnect the pneumatic air-hose and let the remaining air

escape by pressing the switch.

•Never use the steel cutter if you cannot concentrate on your work or if

your mind is diverted. Do by no means use the steel cutter if you are

under the influence of alcohol or tablets.

3