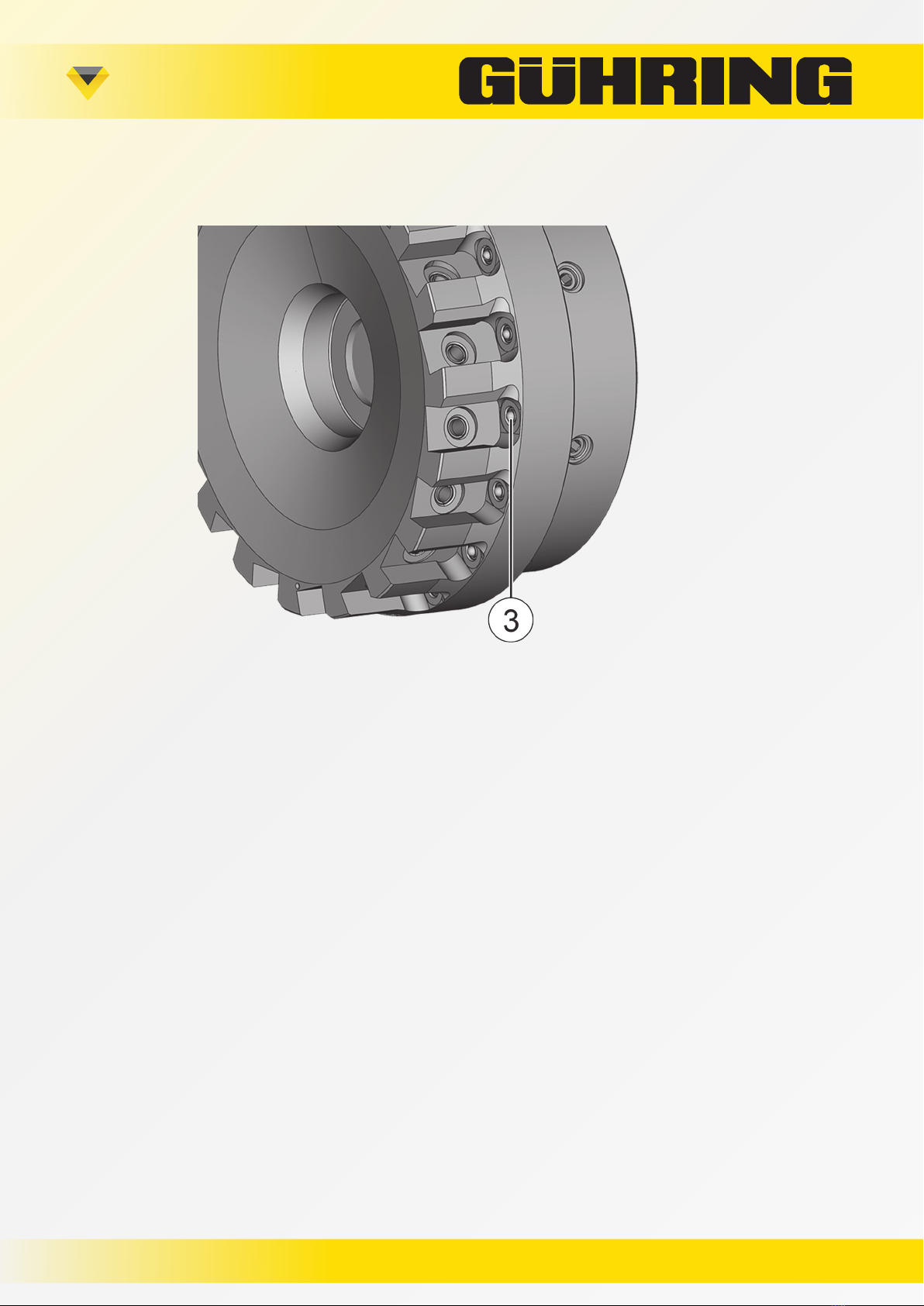

3

1 Information About these Instructions

1.1 Read the Operating Instructions

Use and handling of the tool described below do not come naturally and are not self-explanatory. They

are therefore explained by the accompanying technical documentation.

Theinstructionshelpyoutousethetoolasintended,properly,eectivelyandsafely.Youshouldthere-

fore read the chapters below attentively and thoroughly. If necessary, keep looking up facts that are

essential for your operations.

Request new operating instructions if parts of them are lost or damaged. Always keep the operating

instructions at an accessible place in the vicinity of the tool.

Important information in the enclosed "General Safety Instructions" document

The safety instructions that are necessary for handling the tool can be found in the brief version of the

"General Safety Instructions" that are enclosed with the tool.

Ensure that you read and observe this document.

Residual risks

The documents inform and warn you of residual risks for which the risk mitigation by design and pro-

tectivemeasurestakesnoornocompleteeect.

1.2 Explanation of the General Icons

Icon Explanation

Important information

This icon indicates important additional information.

Information about the machine documentation

This icon refers to other parts of the documentation that must par-

ticularly or additionally be observed (for example in supplier instruc-

tions, etc.).

Tab. 1: General icons