Repair manual HM 1000 / 1000 Marathon®

Version 11/98

Chapter 2

1

2. Operational safety

2.1 General

In order to maintain the operational safety of the

hydraulic hammer, repair work should only be

carried out by trained specialists using genuine

Krupp spare parts. This work should therefore only

be entrusted to Krupp trained specialists who know

which spare parts need replacing and when.

2.2 Accident prevention

regulations

To avoid the possibility of injury, please

observe the following instructions

Before starting work:

Please familiarise yourself with the repair manual

and the appropriate regulations before starting

work on the hydraulic hammer.

When using or working on hydraulic hammers in

the countries of the European Union, the

regulations of the EC machinery directive

98/37/EG must be observed and followed, as must

national accident prevention regulations and

regulations covering pressurised vessels.

In countries outside the European Union, the valid

local statutes and regulations will apply.

The hydraulic hammer should only be repaired by

specialists.

When lifting/transporting the hydraulic hammer,

use only the lug provided and hoisting equipment

with sufficient capacity.

Clear hand signals must be agreed on with the

hoist operator beforehand.

Never stand beneath hoisted loads.

Stand the hydraulic hammer in a suitable device

and secure it against falling over.

The repair area must be clear and easily

accessible.

Always wear protective glasses when fitting or

removing the working tool since metal splinters

may fly off when hammering out the locking pins.

Working tools should only be fitted as described in

the operating manual.

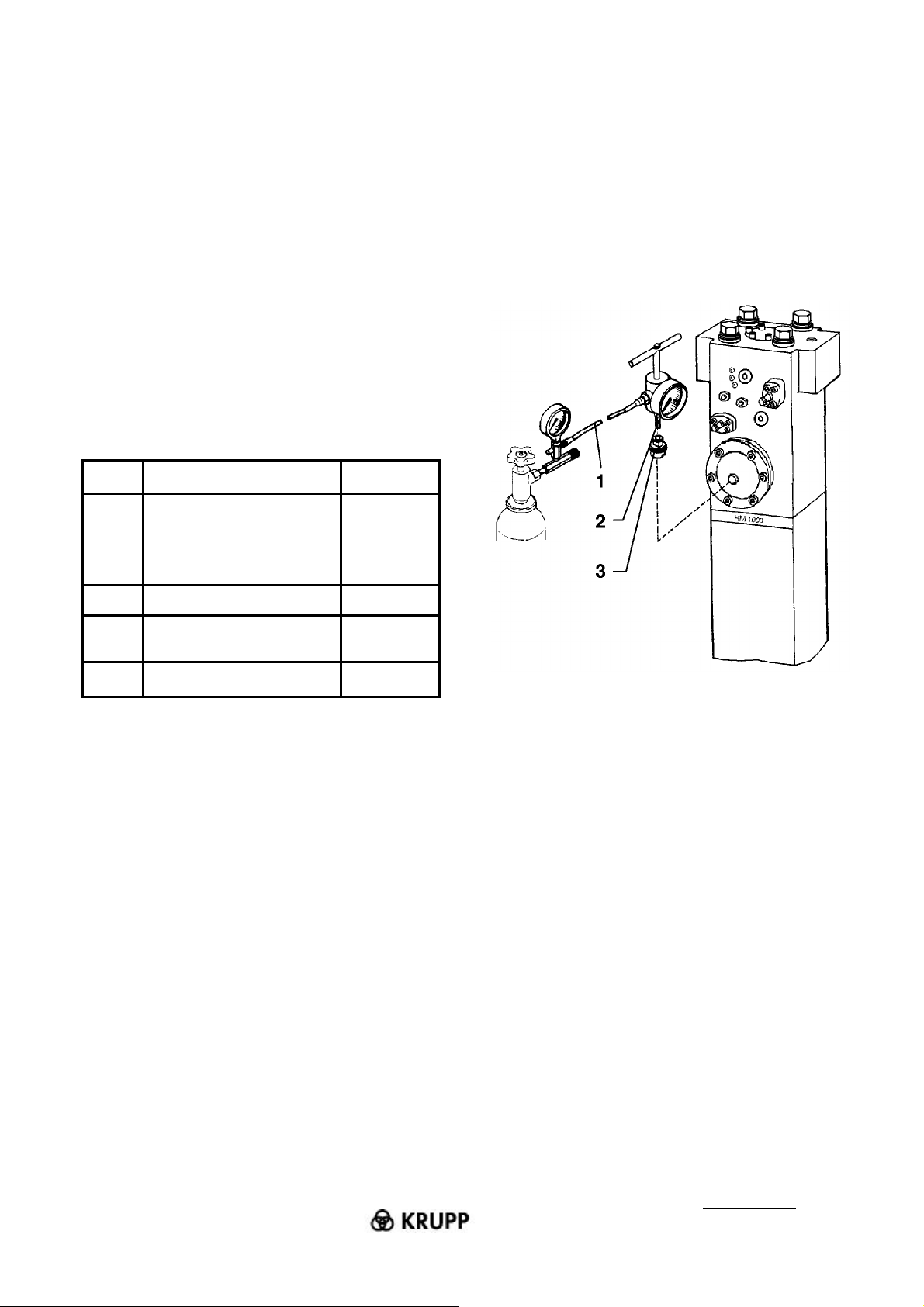

The hammer's integrated piston accumulator is

pressurised.

Before dismantling the hydraulic hammer and

before removing the complete filling valve “G”,

the piston accumulator must be fully

depressurised.

Never use nails, screwdrivers or similar objects to

bleed off the gas since this would damage the

filling valve. Bleed off the gas using only the

nozzle of the filling/test hose.

Never use your fingers to check the alignment of

the working tool recesses to the oblong holes for

the locking bars.

Never dismantle a hydraulic hammer which is still

hot from running as there is a high risk of injury

through burns. Always wait until the hammer has

cooled down before dismantling it. Collect any oil

which runs out and dispose of it correctly.

The piston accumulator must only be filled with

nitrogen from the green cylinder.

Make sure that no other gas (e.g. air or oxygen) is

allowed into the piston accumulator.

When attaching the adapter use only Allen screws

with a material quality of σs= 640 N/mm2(material

quality 8.8)!

Caution!

Caution!

Caution

Risk of explosion!