10

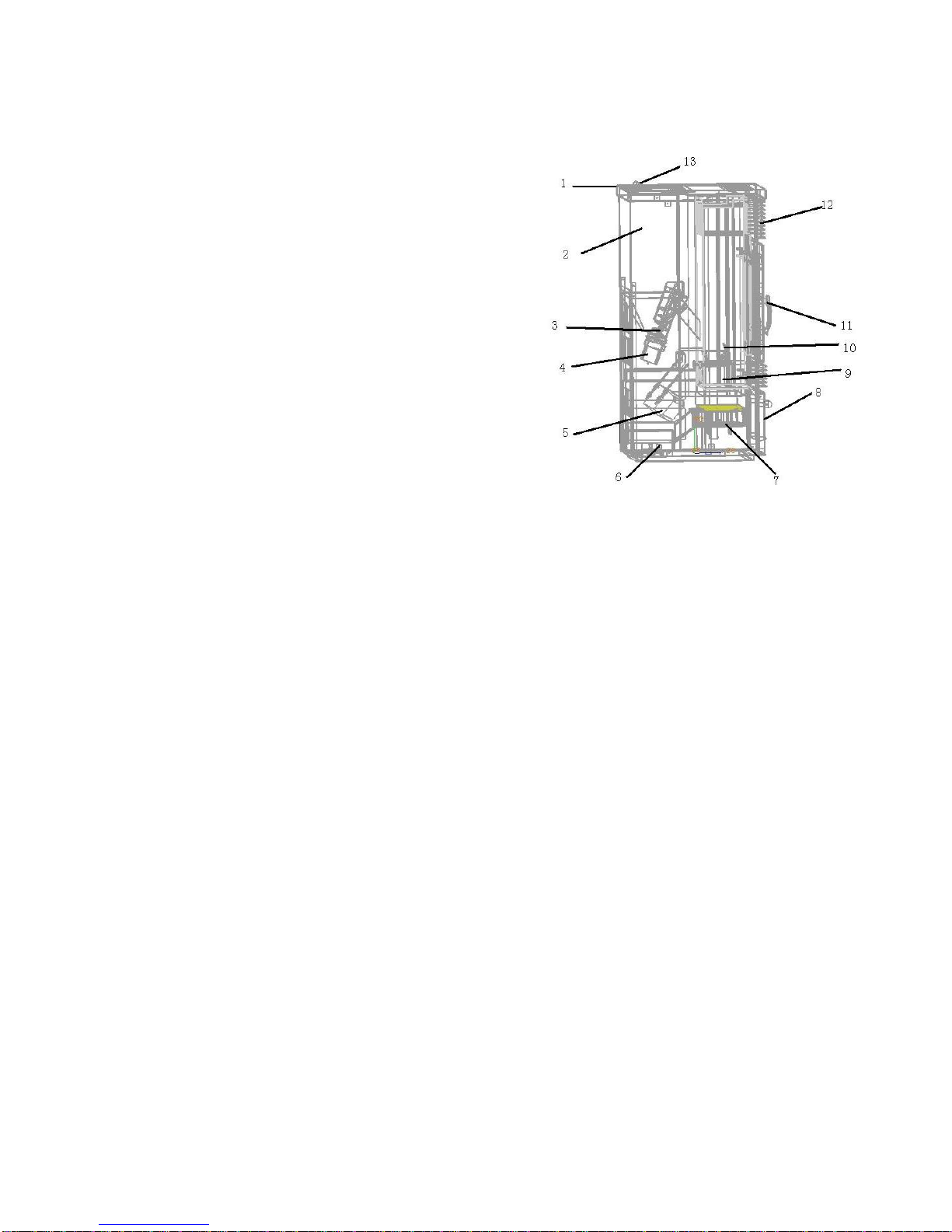

3.Structure instruction

The stove essential components:

1. Hopper covers

2.hopper

3.auger

4. Auger motor

5. convection blower

6.venting pipe

7. Exhaust blower

8.front cover

9.ash drawer

10.fire shield

board

11.stove door

12.heat exchanger

13. Control board

The following is a list of main components and their

functions

IGNITER

The STOVE comes equipped with an automatic igniter

for lighting the fuel when the stove is in lighting mode. There are two ways to light the wood

pellet for our models.

One is the igniter heats wood pellets directly through the burn pot and then lighted by the

combustion blower.

The other one is that the igniter lights the pellet directly. The igniter remains energized

for the first eight minutes of the lighting sequence.

VACUUM SWITCH

The STOVE has s vacuum switch located behind the left door, fastened to the base. If a low

pressure is created in the firebox by a leak, opening the front door, a blocked flue, or unsealed ash

drawer, the vacuum switch will sense it and cause the stove to go into a shutdown mode.

Resetting?

AUGER AND AUGER MOTOR

The 5 RPM auger motor turns the auger, lifting pellets up the auger tube. The pellets are then

dropped down a tube and into the firepot. The auger is controlled by the control board.

OVERHEATING TEMPERATURE SWITCH

This switch is installed on the bottom of hopper and shut off the stove if it senses excessive

temperatures (70 ⁰c). This snap switch can be reset by……..!

CONVECTION BLOWER SWITCH

This switch is installed on the vent pipe and turns the convection blower on when the stove gets up

to temperature (30 ⁰C). It switch off the blower when the temperature goes below 30⁰C.