8

Injury and property damages may be caused.

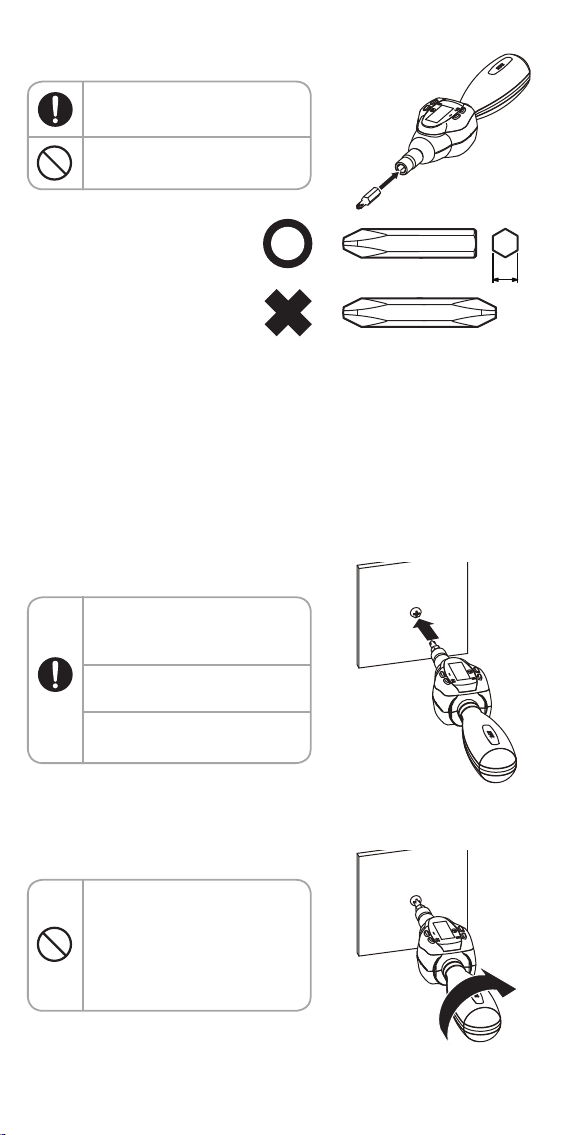

●Precautions for use of the driver type

■Mounting of a driver bit

For working procedures for disassembly and assembly of work objects and handling

of new parts, follow the maintenance instructions of each manufacturer, etc.

Injury and property damages may be caused.

Note

Note

● Do not extend the grip by

pipes, etc.

The main unit or other properties

may be damaged.

● Do not use the product for

any electrified work object.

Electric shock and property

damages may be caused.

●

For any high-place work, be sure to

implement safety measures.

Injury and property damages

may be caused.

●

Do not use the product out of the

specification range, e.g. overload.

Damages may be caused.

● Do not use any tip tool "at

an angle" or "with

insufficient engagement".

Injury and property damages

may be caused by slippage or

fall-off.

● Do not hit the main unit by

foot or strike it by a

hammer to give a shock.

Injury and damages of the main

unit or other properties may be

caused.

● Do not use the product in

an unstable place or at an

improper posture.

Injury and damages of the main

unit or other properties may be

caused.

● If any abnormal sound,

etc. occurs during work,

immediately stop working.

Injury and damages of the main

unit or other properties may be

caused.

● Do not use the product as

a chisel or lever.

Injury and damages of the main unit

or other properties may be caused.

Picture

indication

Important items Harm and damage

● Check for any crack or

damage on the tip tool.

Injury and damages of the main unit

or other properties may be caused.

● Do not swing around the

main unit

The main unit or other properties

may be damaged.

●

Use a driver bit appropriate

for respective conditions.

Damages may be caused.

Picture

indication

Important items Harm and damage