20417320

11-2004/Rev 0 iii

7Hydraulic System.............................................................................................7-1

7.1 Overview...............................................................................................7-1

7.2 Operation...............................................................................................7-2

7.3 Service and Maintenance Procedures ...................................................7-3

Hydraulic Operating Pressure...............................................................7-4

Motor Maintenance...............................................................................7-5

Flexible Coupling Replacement............................................................7-6

Hydraulic Compensator Maintenance...................................................7-8

Hydraulic Pump or Electric Motor Replacement..................................7-11

8Electrical System..............................................................................................8-1

8.1 Overview...............................................................................................8-1

8.2 Operation...............................................................................................8-1

Sensors and Solenoids...........................................................................8-4

8.3 Service and Maintenance Procedures ...................................................8-8

Proximity Switch Maintenance.............................................................8-8

Optical Relay Maintenance...................................................................8-9

9High Pressure Water System ..........................................................................9-1

9.1 Overview...............................................................................................9-1

9.2 Operation...............................................................................................9-2

9.3 System Components..............................................................................9-4

9.4 Service and Maintenance Overview .....................................................9-5

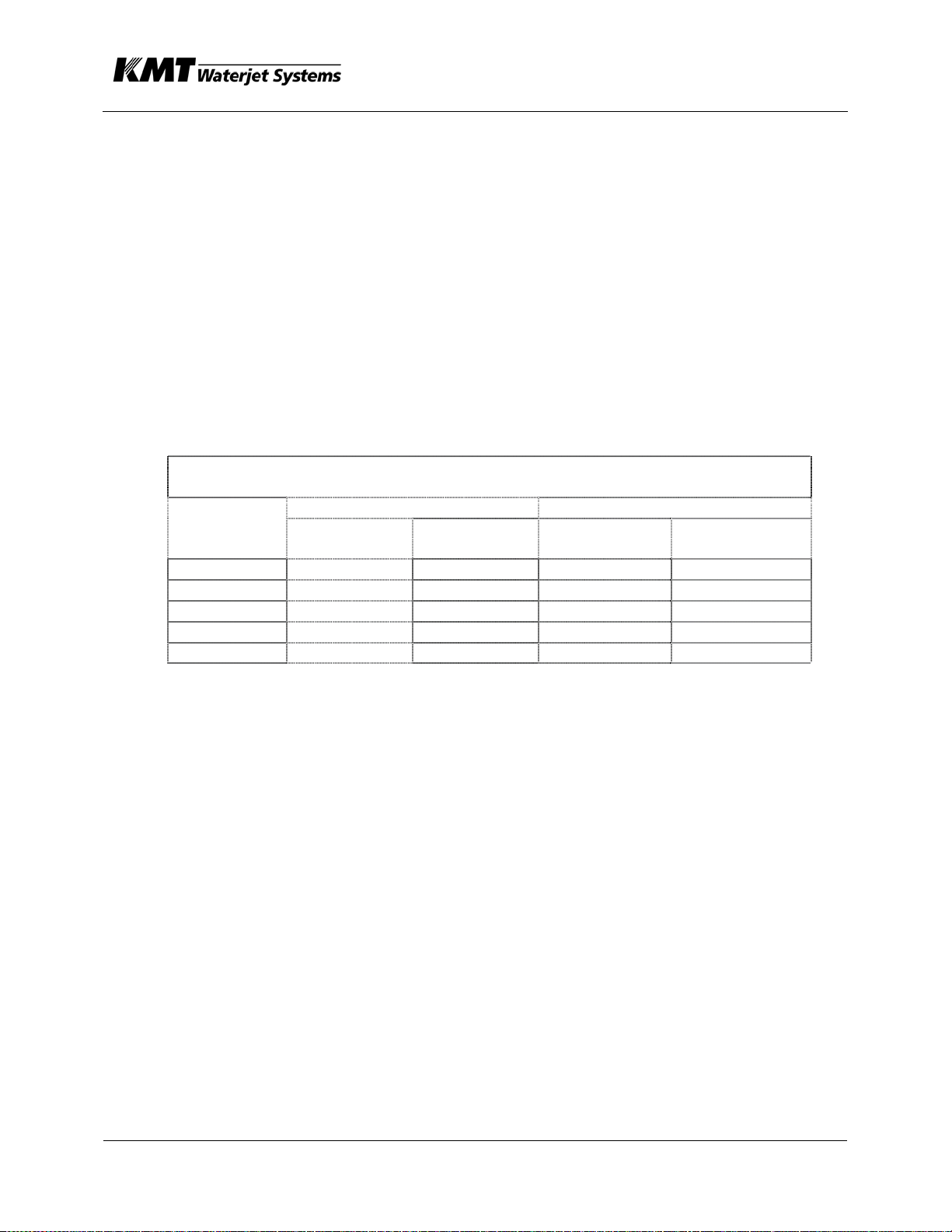

Torque Specifications ...........................................................................9-6

Specialized Maintenance Tools ............................................................9-8

9.5 High and Low Pressure Water Piping...................................................9-9

9.6 High Pressure Cylinder Assembly........................................................9-9

High Pressure Cylinder Assembly Removal.........................................9-10

High Pressure Cylinder Assembly Installation.....................................9-12

High Pressure Cylinder Maintenance ...................................................9-13

9.7 Hard Seal End Caps ..............................................................................9-13

Hard Seal End Cap Removal ................................................................9-13

Hard Seal End Cap Installation.............................................................9-14

9.8 Sealing Head.........................................................................................9-15

High Pressure Discharge Check Valve.................................................9-15

Low Pressure Inlet Check Valve...........................................................9-17

Sealing Head Maintenance ...................................................................9-18

9.9 High Pressure Seal Assembly...............................................................9-19

9.10 Hydraulic Cartridge Seal Replacement.................................................9-21

Hydraulic Cartridge Seal.......................................................................9-22

9.11 Hydraulic Piston and Plungers..............................................................9-24

Hydraulic Piston and Plunger Removal................................................9-25

Bearing Rings and Seal Assembly........................................................9-26

Plunger Maintenance ............................................................................9-27

Hydraulic Piston and Plunger Installation ............................................9-28

9.12 Hydraulic Cylinder Maintenance..........................................................9-29

9.13 High Pressure Attenuator......................................................................9-29

9.14 High Pressure Dump Valve ..................................................................9-29

Pneumatic Control Valve......................................................................9-31