Declaration of conformity

Contents

1. For your safety ...................................................................................... 3

Symbols used in these instructions .................................................................... 3

Warning signs on the screw capping machine ................................................... 3

During emergencies ........................................................................................... 3

Safe working environment.................................................................................. 3

Stability of the plant ............................................................................................ 3

Safety devices .................................................................................................... 4

Intended use....................................................................................................... 4

For the environment ........................................................................................... 4

Safe transportation ............................................................................................. 4

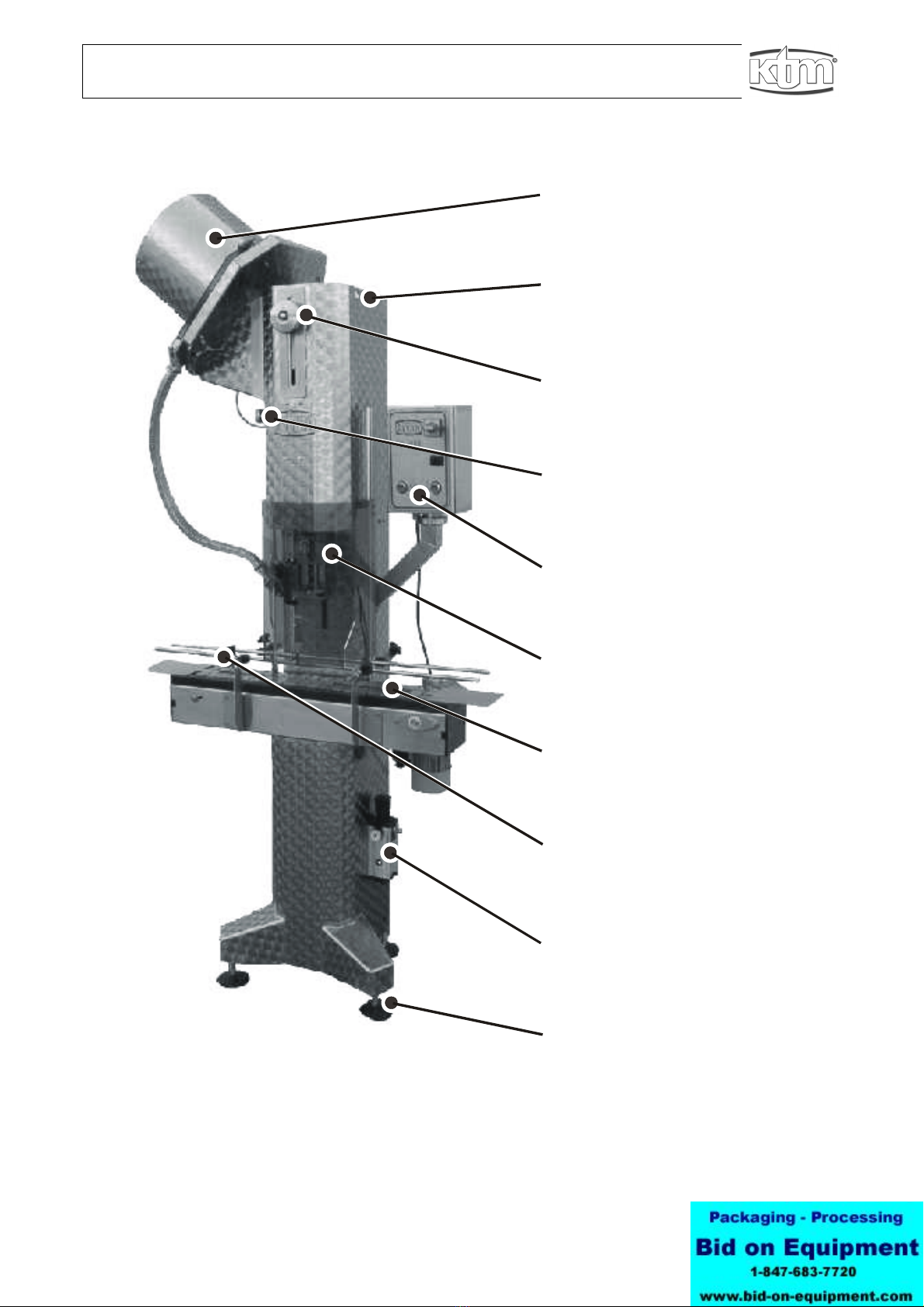

2. Overview of screw capping machine.................................................. 5

3. Operator controls on switching unit................................................... 6

4. Adjusting the TV 2000............................................................................ 7

Preparing the capping unit.................................................................................. 7

Sterilising the screw capping machine................................................................ 7

Adjusting the bottle cap feeder to the bottle height............................................. 8

Adjusting the bottle guide to the bottle diameter................................................. 8

Assembling the capping unit............................................................................... 9

Dismantling the screw cap separator prior to transportation............................. 10

5. Technical Data..................................................................................... 11

6. Maintenance and Care........................................................................ 12

After the work has been completed .................................................................. 12

7. Assistance in case of malfunctions .................................................. 13

Troubleshooting instructions............................................................................. 13

Fault table......................................................................................................... 13

8. Accessories ......................................................................................... 14

9. Appendix.............................................................................................. 14

Parameter change for Siemens LOGO!........Fehler! Textmarke nicht definiert.

Circuit diagram for electricians .....................Fehler! Textmarke nicht definiert.

EU declaration of conformity..................................................................... 15