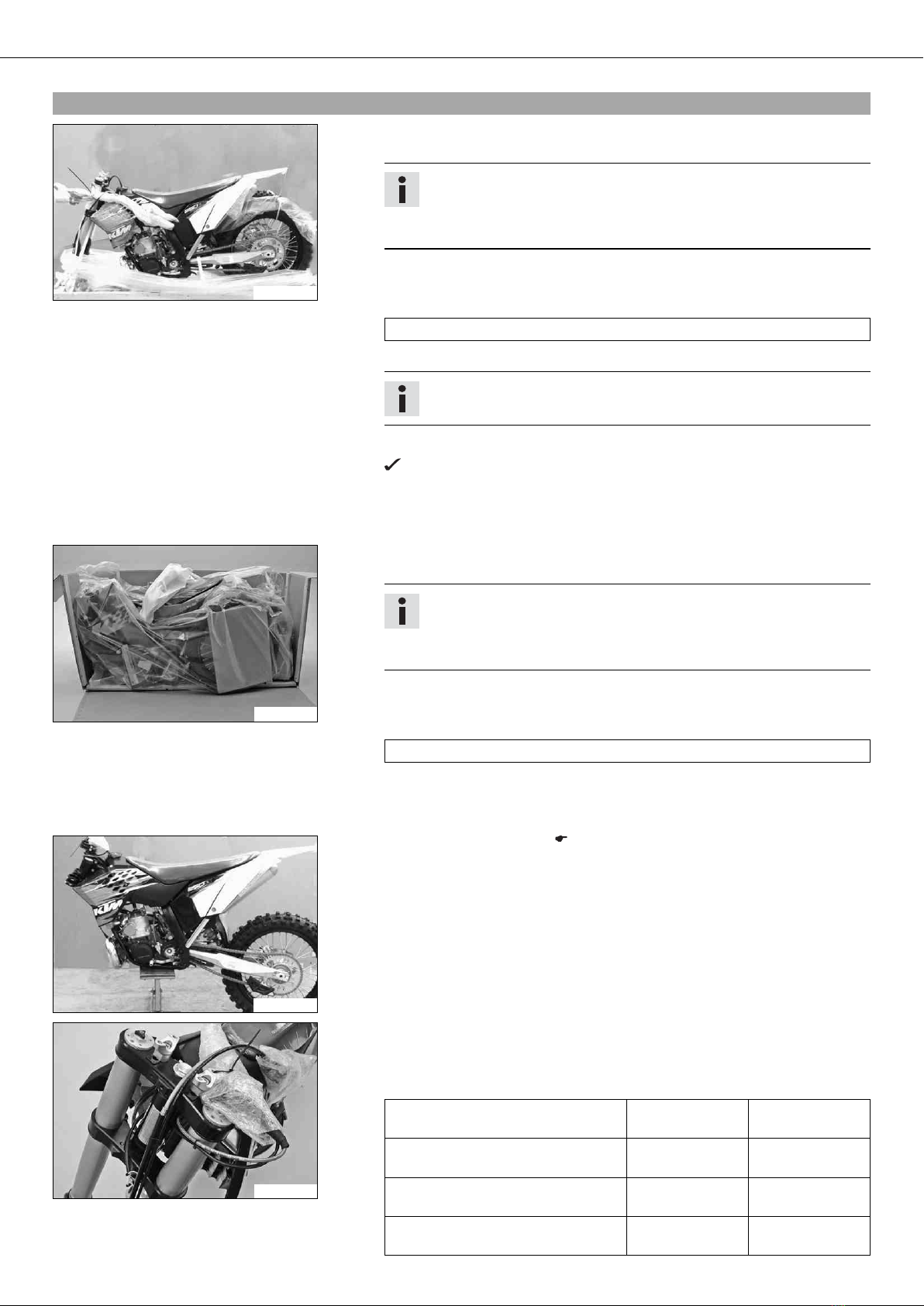

WORK 8

Guideline

Screw, bottom shock

absorber

M12 80 Nm

(59 lbf ft)

Loctite®2701

Info

The heim joint for the shock absorber at the swing arm is Teflon coated.

It must not be lubricated with grease or with other lubricants. Lubri-

cants dissolve the Teflon coating, thereby drastically reducing the ser-

vice life.

–Remove the motorcycle from the lift stand.

3.4Installing the front wheel

Warning

Danger of accidents Reduced braking efficiency due to oil or grease on the brake discs.

–Always keep the brake discs free of oil and grease, and clean them with brake cleaner when necessary.

500086-11

–Check the wheel bearing for damage and wear.

» If the wheel bearing is damaged or worn:

–Change the wheel bearing.

–Clean and grease shaft seal rings and bearing surface of the spacers.

Long-life grease ( p. 14)

–Insert the spacers.

500084-11

–Lift the front wheel into the fork, position it, and insert the wheel spindle.

–Mount and tighten screw .

Guideline

Screw, front wheel spindle M24x1.5 45 Nm

(33.2 lbf ft)

–Operate the hand brake lever several times until the brake linings are lying correctly

against on the brake disc.

–Remove the motorcycle from the lift stand.

–Pull the front wheel brake and push down hard on the fork several times to align

the fork legs.

–Tighten screws .

Guideline

Screw, fork stub M8 15 Nm

(11.1 lbf ft)

3.5Recharging the battery (All 250/300 models)

Warning

Risk of injury Battery acid and battery gases cause serious cauterization.

–Keep batteries out of the reach of children.

–Wear suitable protective clothing and goggles.

–Avoid contact with battery acid and battery gases.

–Keep the battery away from sparks or open fire. Charge only in well ventilated rooms.

–Flush with copious amounts of water in case of skin contact. If battery acid comes into contact with the eyes, flush the

eyes with water for at least 15 minutes and consult a physician.

Warning

Environmental hazard Battery parts and acid are harmful to the environment.

–Do not discard batteries with the household trash. Dispose of a defective battery in an environmentally compatible manner.

Give the battery to your KTM dealer or to a recycling center that accepts used batteries.