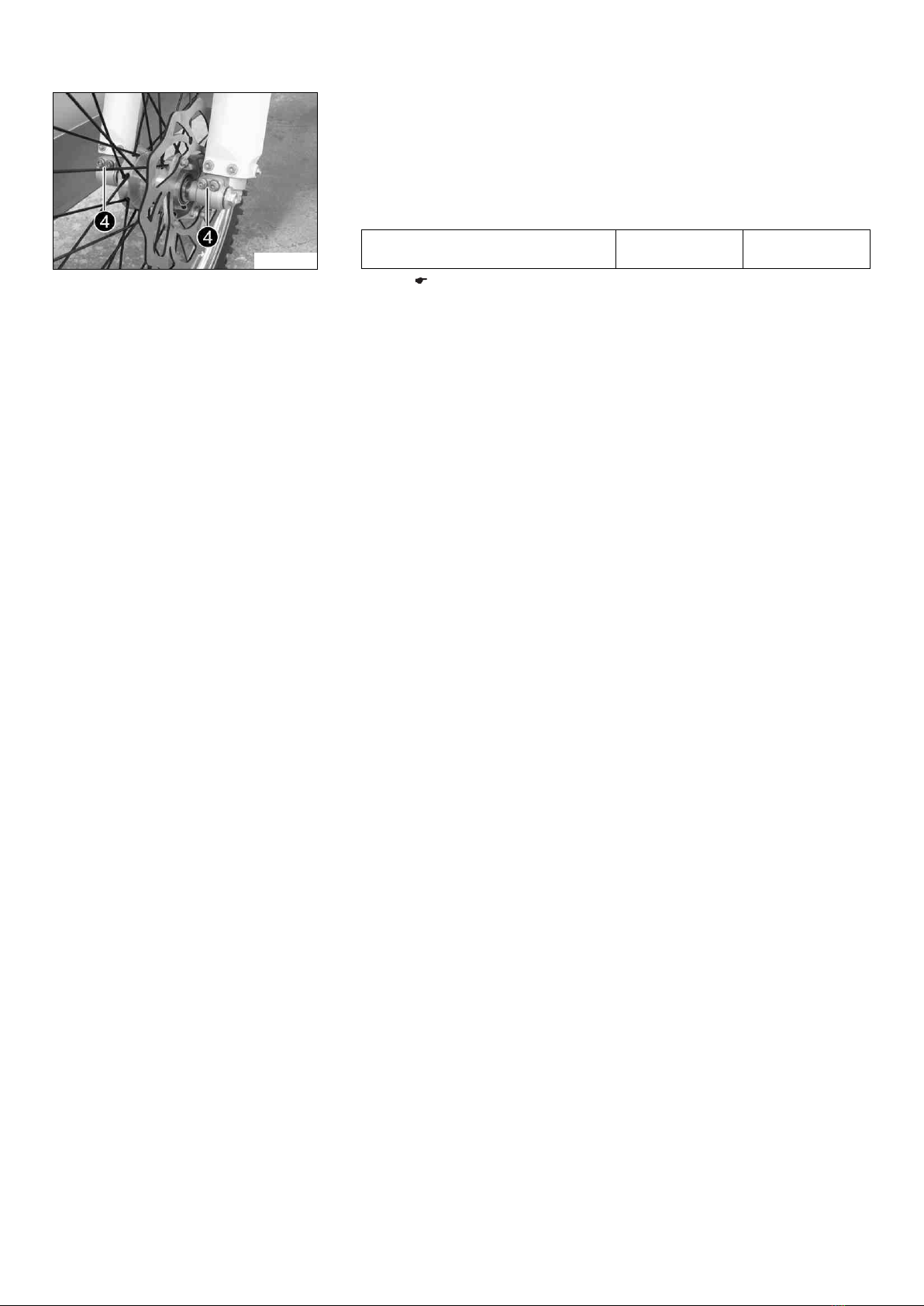

3 WORK 7

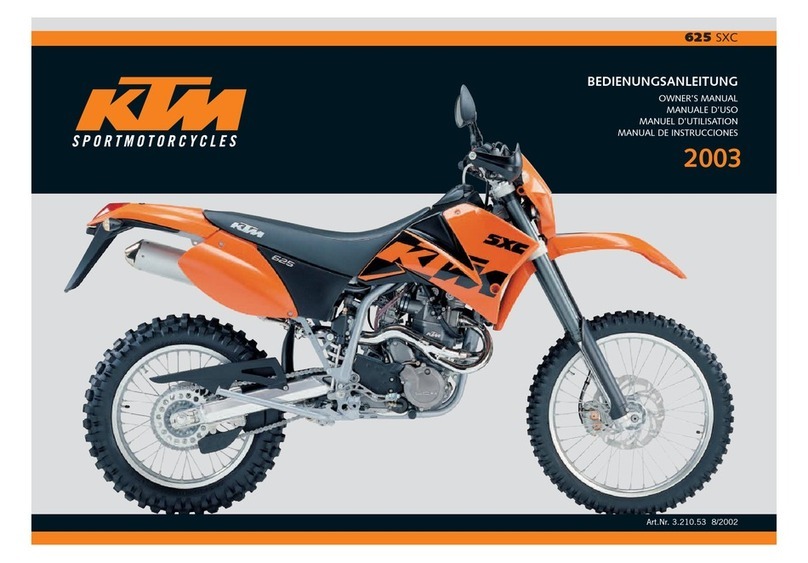

–Pull the front wheel brake and push down hard on the fork several times to align

the fork legs.

–Tighten screws 3.

Guideline

Screw, fork stub M8 15 Nm

(11.1 lbf ft)

Finishing work

–Remove the motorcycle from the lift stand. ( p. 6)

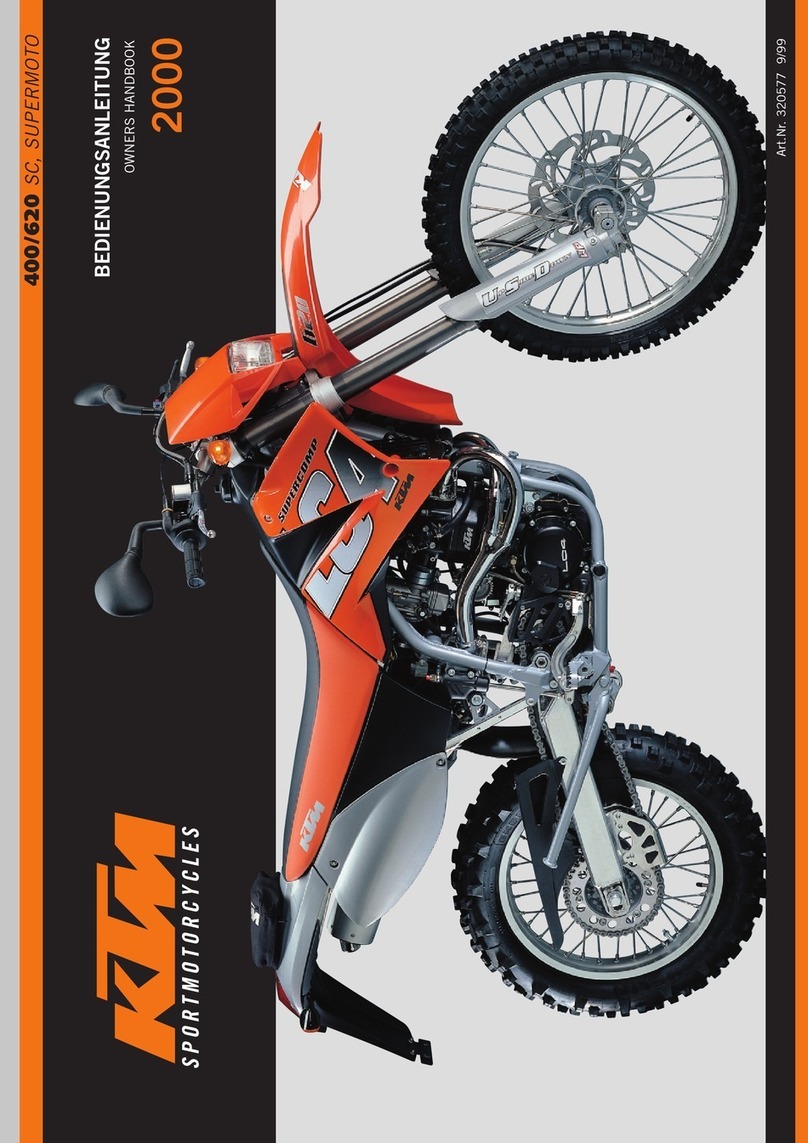

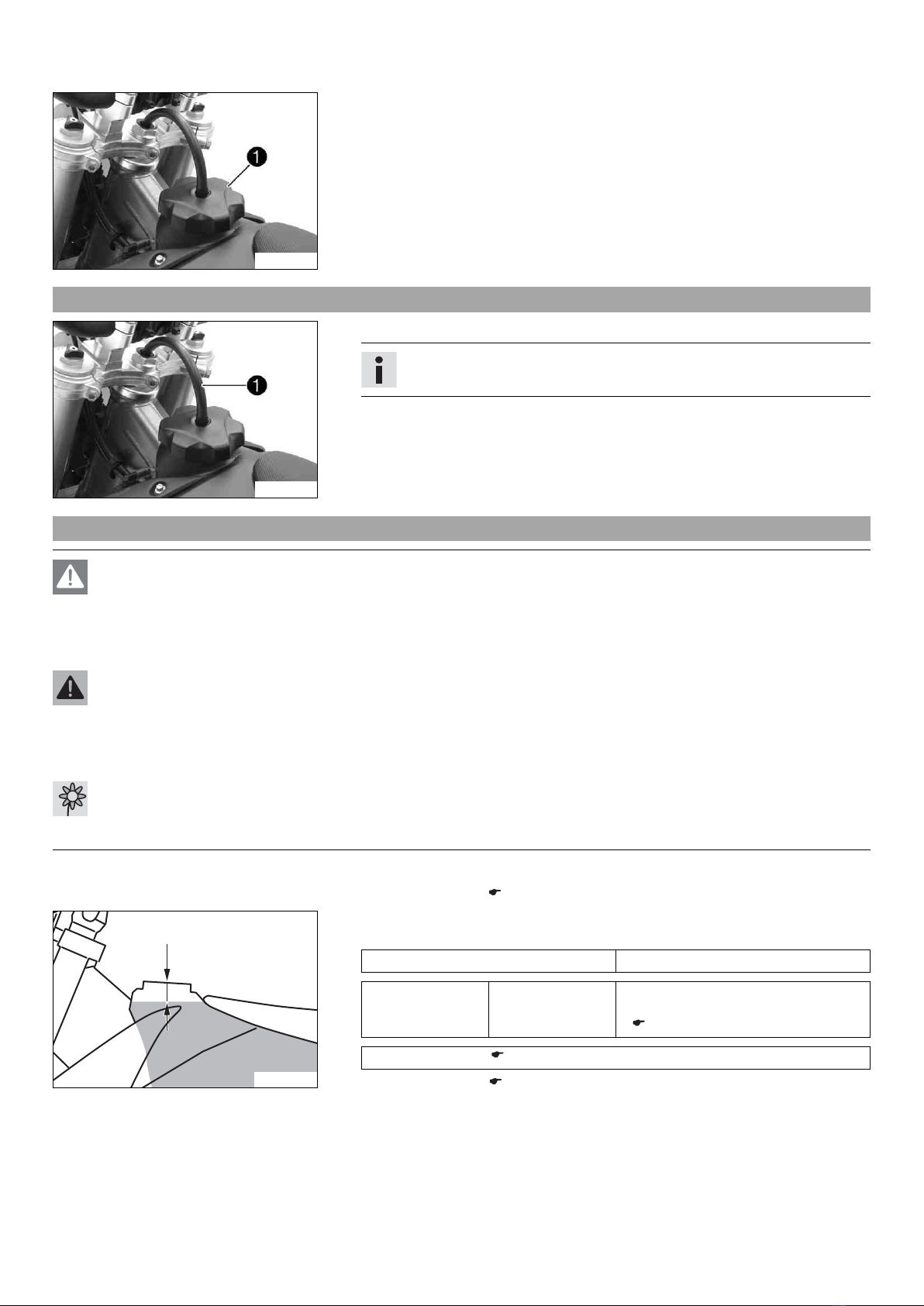

3.4 Installing the front fender

L00040-10

–Ensure that the spacers are mounted in the fender.

–Position the front fender. Mount and tighten screws 1.

Guideline

Remaining screws, chassis M6 10 Nm (7.4 lbf ft)

Info

Make sure the holding lugs engage in the start number plate.

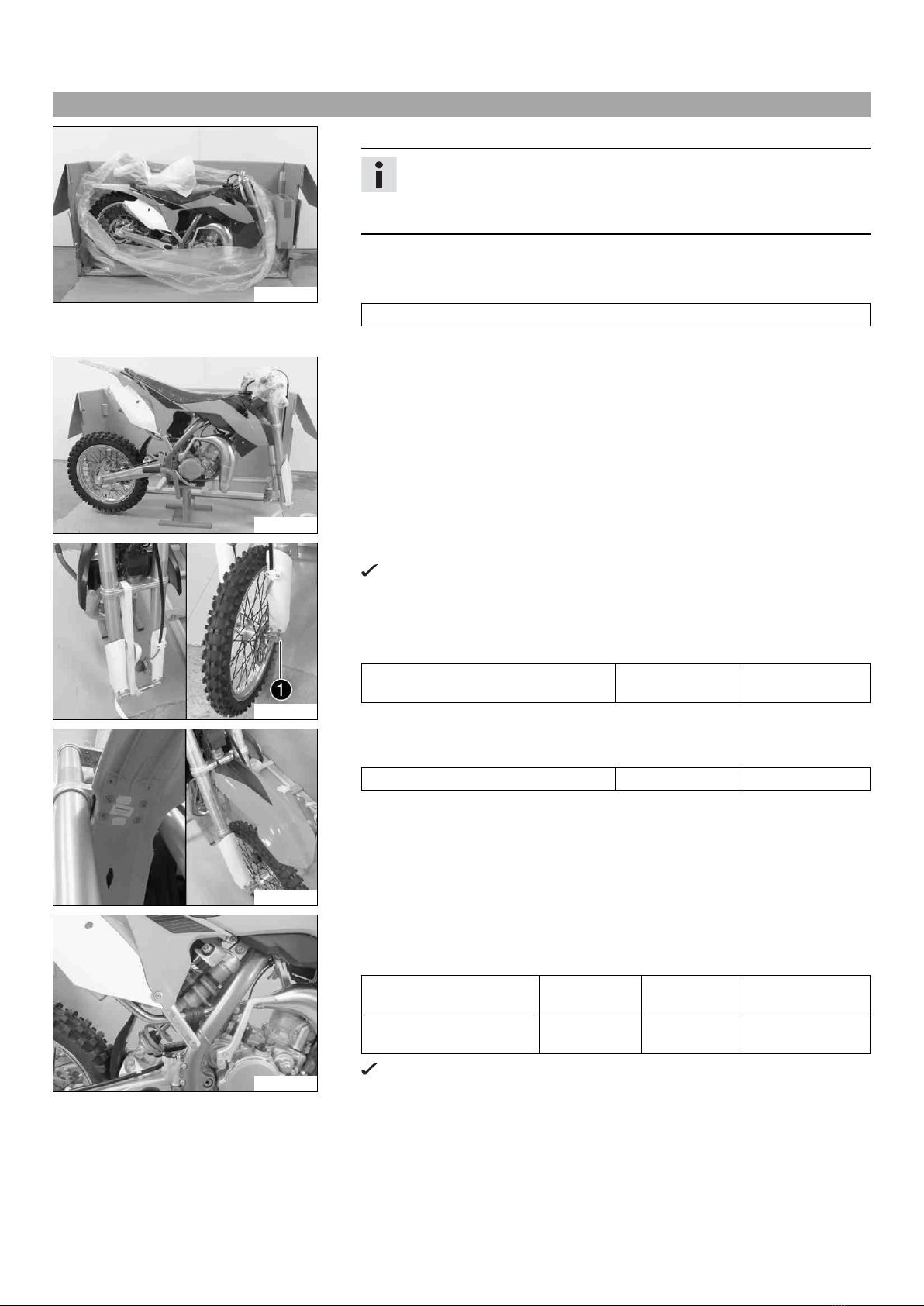

3.5 Installing the start number plate

L00049-10

–Position the start number plate. Mount and tighten screw 1.

Guideline

Remaining screws, chassis M6 10 Nm (7.4 lbf ft)

Info

Make sure that the holding lugs engage in the fender.

–Position the brake line and clamp. Mount and tighten screw 2.

3.6 Opening the filler cap

Danger

Fire hazard Fuel is highly flammable.

–Never refuel the vehicle near open flames or burning cigarettes, and always switch off the engine first. Be careful that no

fuel is spilt, especially on hot vehicle components. Clean up spilt fuel immediately.

–Fuel in the fuel tank expands when warm and can escape if the tank is overfilled. See the notes on refueling.

Warning

Danger of poisoning Fuel is poisonous and a health hazard.

–Avoid contact between fuel and skin, eyes and clothing. Do not inhale fuel vapors. If fuel gets into your eyes, rinse immedi-

ately with water and contact a doctor. Wash affected skin areas immediately with soap and water. If fuel is swallowed, con-

tact a doctor immediately. Change clothing that has come into contact with fuel. Store fuel in a suitable canister according

to regulations and keep it out of the reach of children.

Warning

Environmental hazard Improper handling of fuel is a danger to the environment.

–Do not allow fuel to get into the ground water, the ground, or the sewage system.