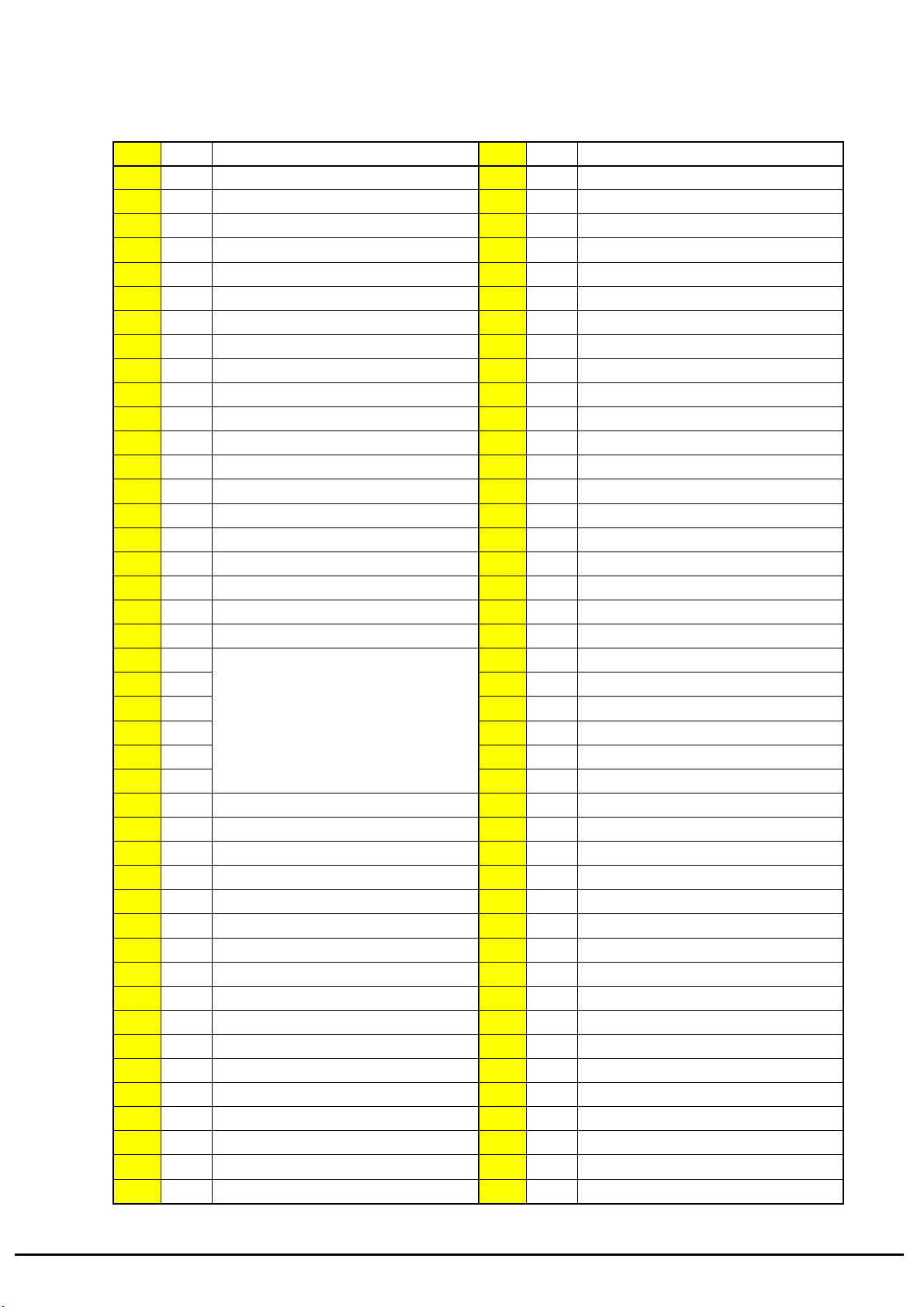

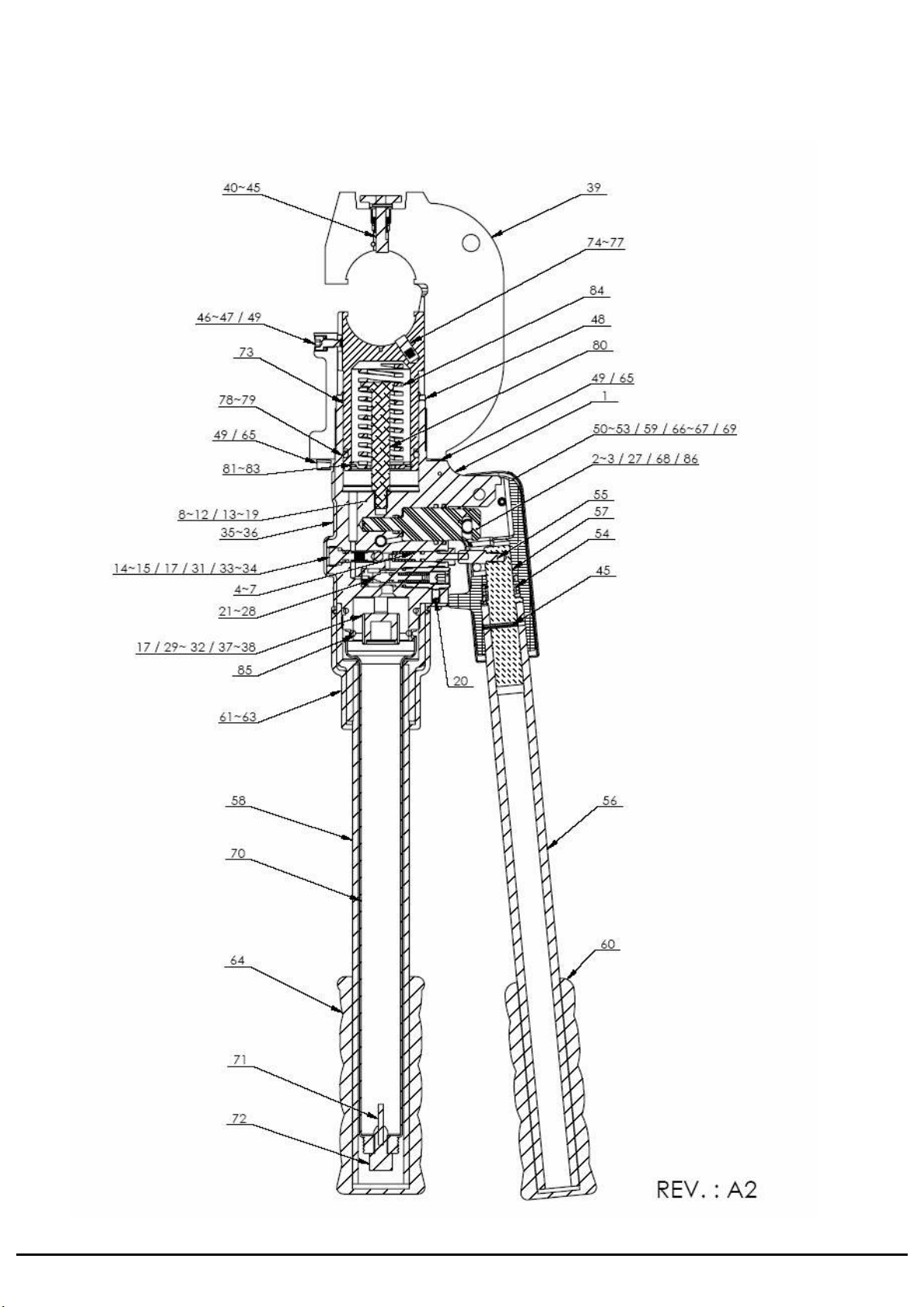

2 1 Dust Seal 45 2 Spring Pin

3 1 O-Ring 46 1 Socket Head Cap Screw

4 1 Locating Screw 47 1 Guide Block

5 1 Release Lever 48 1 Dust Seal

6 1 O-Ring 49 3 Spring Washer

7 1 Compression Spring 50 1 Cap

8 2 Valve Screw 51 1 Spring Pin

9 2 Compression Spring 52 4 Bushing

10 2 Ball 53 1 Conical Pin

11 1 Compression Spring 54 1 Torsional Spring

12 1 Ball 55 1 Release Pin

13 1 Screw 56 1 FRP Pipe

14 2 Back Up Ring 57 1 Guide Bult

15 2 O-Ring 58 1 Insulation Cap

16 1 Compression Spring 59 1 Robber Handle Tube

17 3 Ball 60 1 Extention Tube

18 1 Set Screw 61 1 FRP Pipe

19 1 Ball 62 1 Spring Pin

20 1 Set Screw 63 1 Insulation Tube

21 1 64 1 Rubber Handle Tube

22 1 65 2 Socket Head Cap Screw

23 1 66 2 Crescent

24 1 67 1 Hinge Pin

25 1 68 1 Pumping Piston

26 1

Relief Valve Set

69 1 Arresting Pin

27 2 O-Ring 70 1 Oil Bag

28 1 O-Ring 71 1 Magnetic Bar

29 1 Solid Filter 72 1 Bung

30 1 Push-In Fastener 73 1 Main Piston

31 2 Compression Spring 74 1 Arresting Pin

32 1 Screw 75 1 Spring

33 1 Ball Seat 76 1 Compression Spring

34 1 Screw 77 1 Locating Pin

35 1 Insulation Cover 78 1 Back Up Ring

36 1 Hook Spring 79 1 O-Ring

37 1 O-Ring 80 1 Spring Rod

38 1 Funnel 81 1 Compression Spring Support

39 1 C Head 82 1 Inverse Ring

40 1 Spring Pin 83 1 Spring Pin

41 1 Locating Ring 84 1 Compression Spring

42 1 Stop Screw 85 1 O-Ring

43 1 Compression Spring 86 1 Back Up Ring

KuDos Industrial Inc. U.S.A. Page: 12