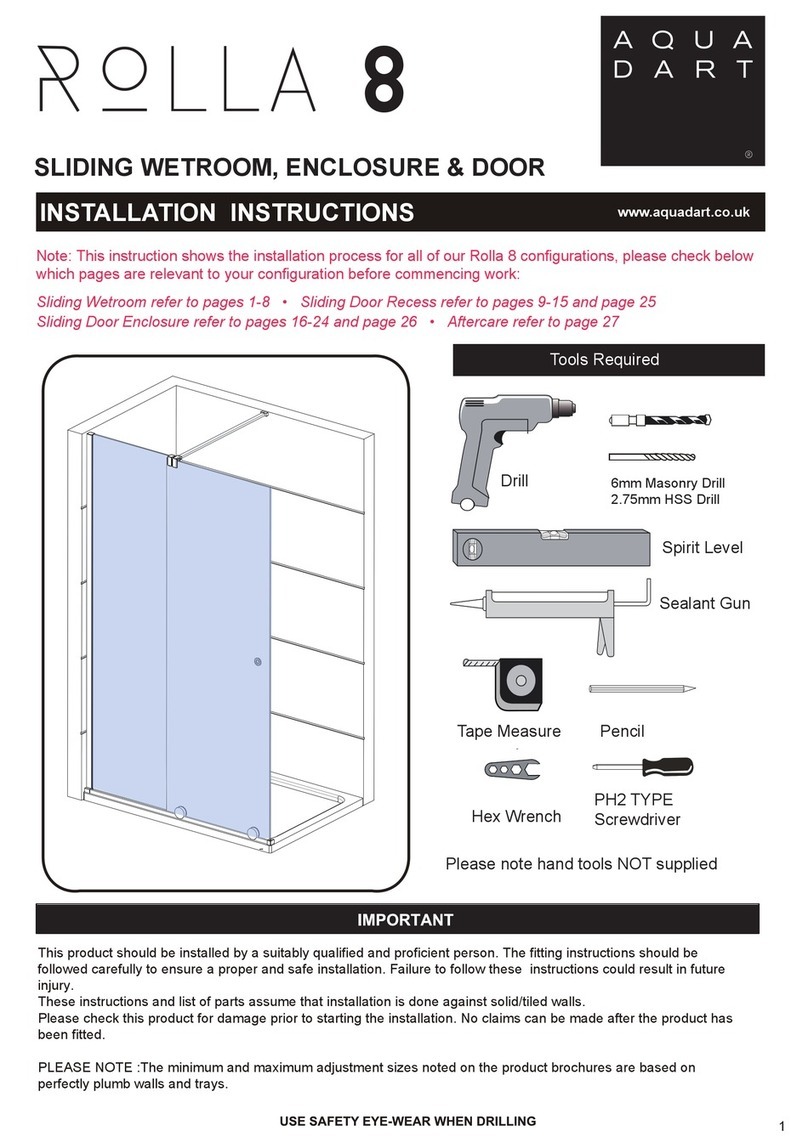

6Issue 01 MAR.19

Step 19 - Fit Seal to Fixed Glass Panel

1. Uncoil the two ‘Glazing Wedge Seals (PlexF05),’ Insert the seals to

the outside of the enclosure, between the xed glass panel and lip of

the metal frame, along the vertical side, and also along the bottom edge.

Inserting the glazing seal, starting at top and working downwards, trim

excess length. If tight, lubricate glazing seal with water. Do not stretch

seal when inserting, because, after cutting to length, the seal will shrink

and leave a gap.

If the seal is misshapen, soak in warm water, not boiling, for 2-3 minutes

prior to use.

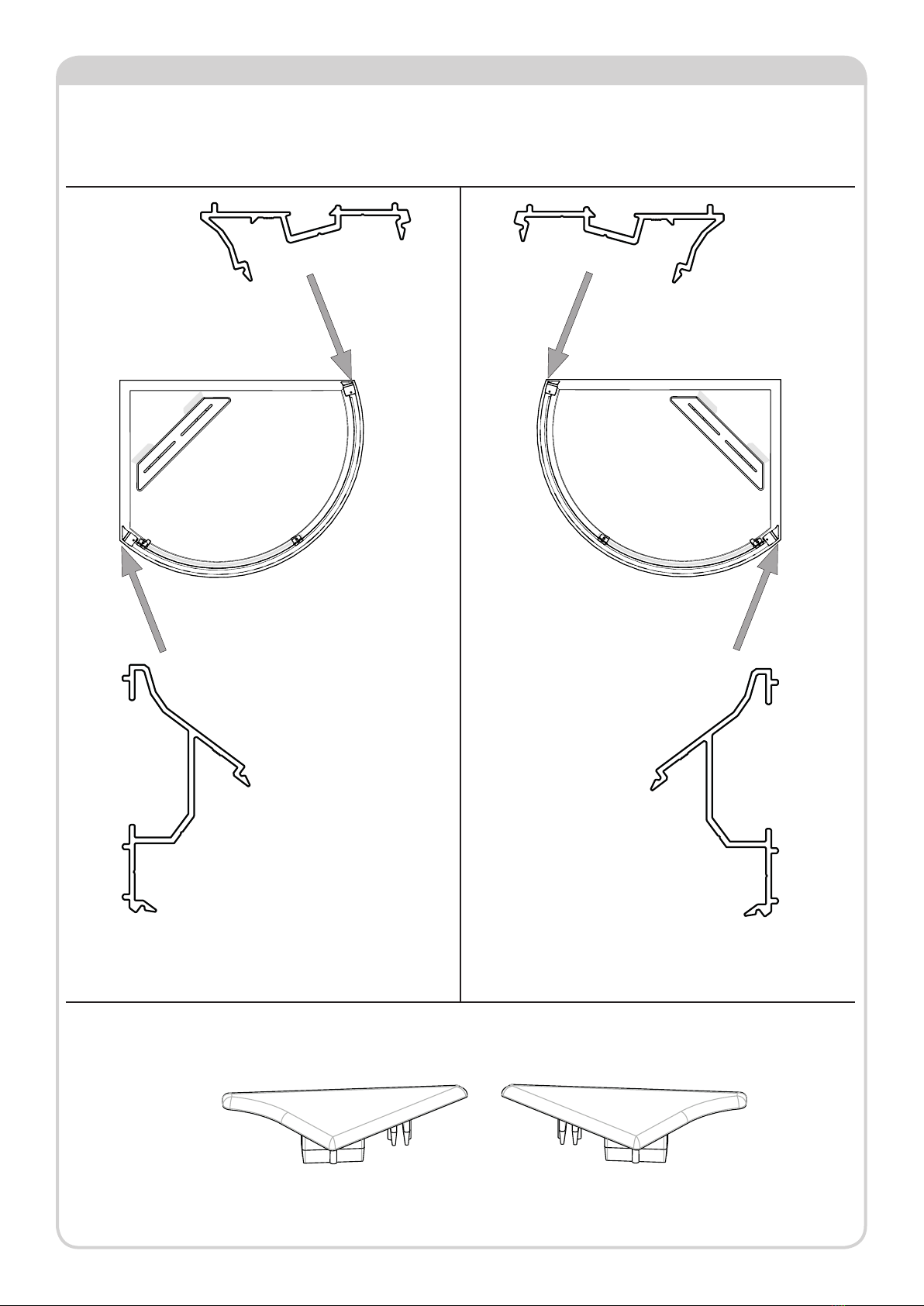

Step 17 - Ret Clip-In Extrusions

2. Relocate the clip-in extrusions down the in side of each post, rotate and

press the clip-in extrusion at top, middle and bottom of each prole, to

gently press-in and reattach the extrusions down each entire length.

1. Replace the clip-in extrusions from Step 5, ensuring left and right are

correctly repositioned. (Handing shown below for example only).

Door Opening Side Fixed Panel Side Door Opening Side Fixed Panel Side

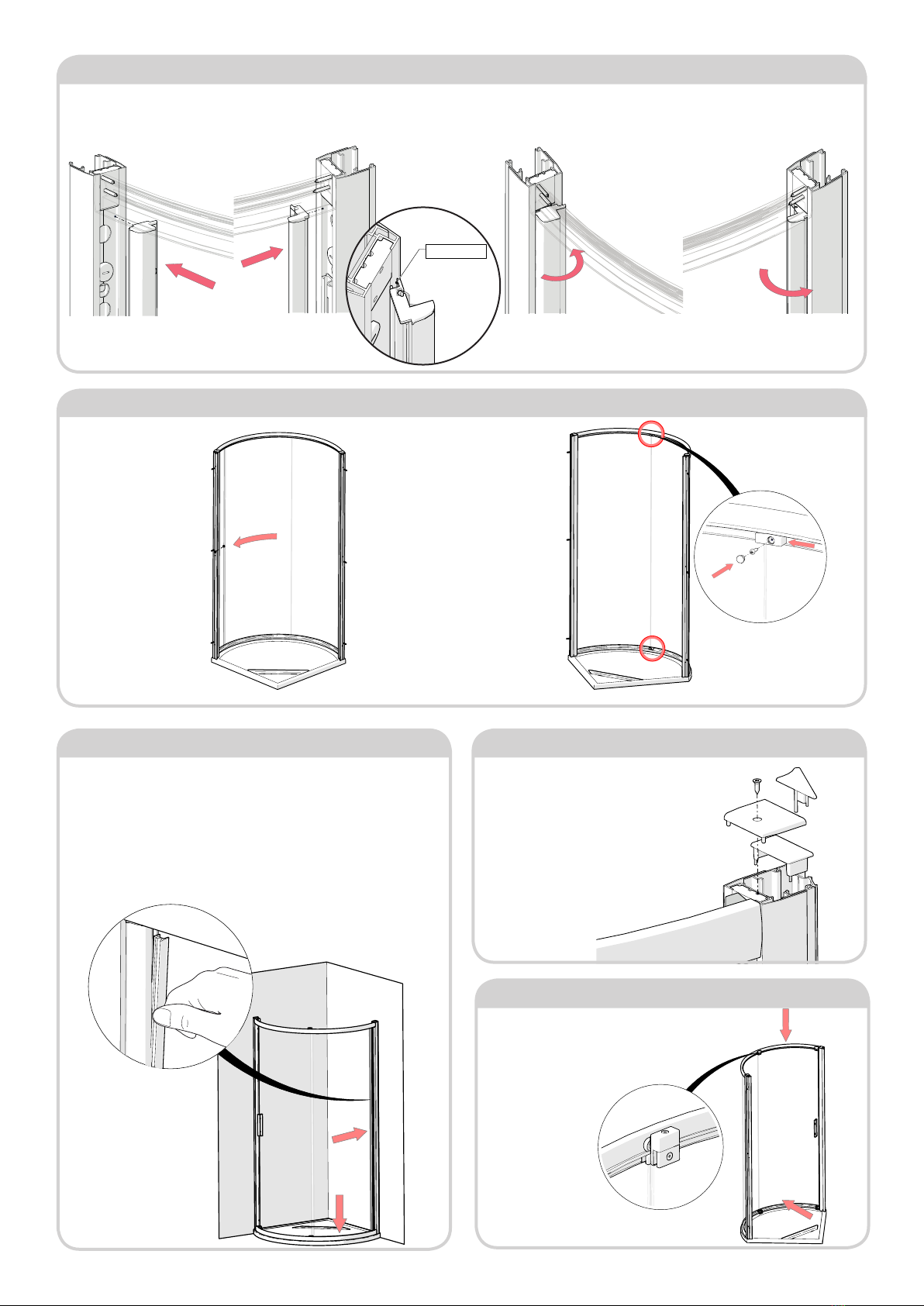

Step 18 - Fit Fixed Glass Panel

1. Carefully t Fixed Glass

Panel into slot in wall-

post, ensuring the panel is

concentric with the rail and

vertical to the wall post. Tap

the plastic prole rmly into

groove of clip-in extrusion

along full length, if this is not

done, the xed panel glass

may interfere with the door

glass when this is installed.

(Handing shown for example

only).

Tip. Use your foot to steady

the bottom of the glass and

prevent it slipping off the

curved rail.

2. Take the Glass Patch Clamp

assemblies (DCM-85-ASM), and

place them at the top and bottom

corners of the glass at the centre of

the enclosure.

Next take the two No.6x12 Phillips

Head screws, pushing the glass as

far round as possible, ensuring the

glass is still concentric to the rails top

and bottom. Tighten the two screws

into the two clamps, ensuring the

screws engage centrally with the

two pre-drilled pilot holes in the

curved rails. Finally, ‘push t’ the

Patch Guide Caps (M276-01) into

the two clamps.

Step 20 - Fit Cover Caps

1. At both top corners, t the inner

‘Comp. Chnl. Top Caps (M56-02)’

followed by the ‘Wall Jamb Top Caps

(M56-01) and the Top Caps left and

right (M73-01 & M73-02) .’ Securing

in place with the No.4x10mm CSK

screws provided.

Step 21 - Fit Glass Door

1. Fit the glass door, by rst lifting the door into

position with both sets of wheels sitting in the top

rail prole. The rail should now take the doors

weight.