4Issue 01 MAR.19

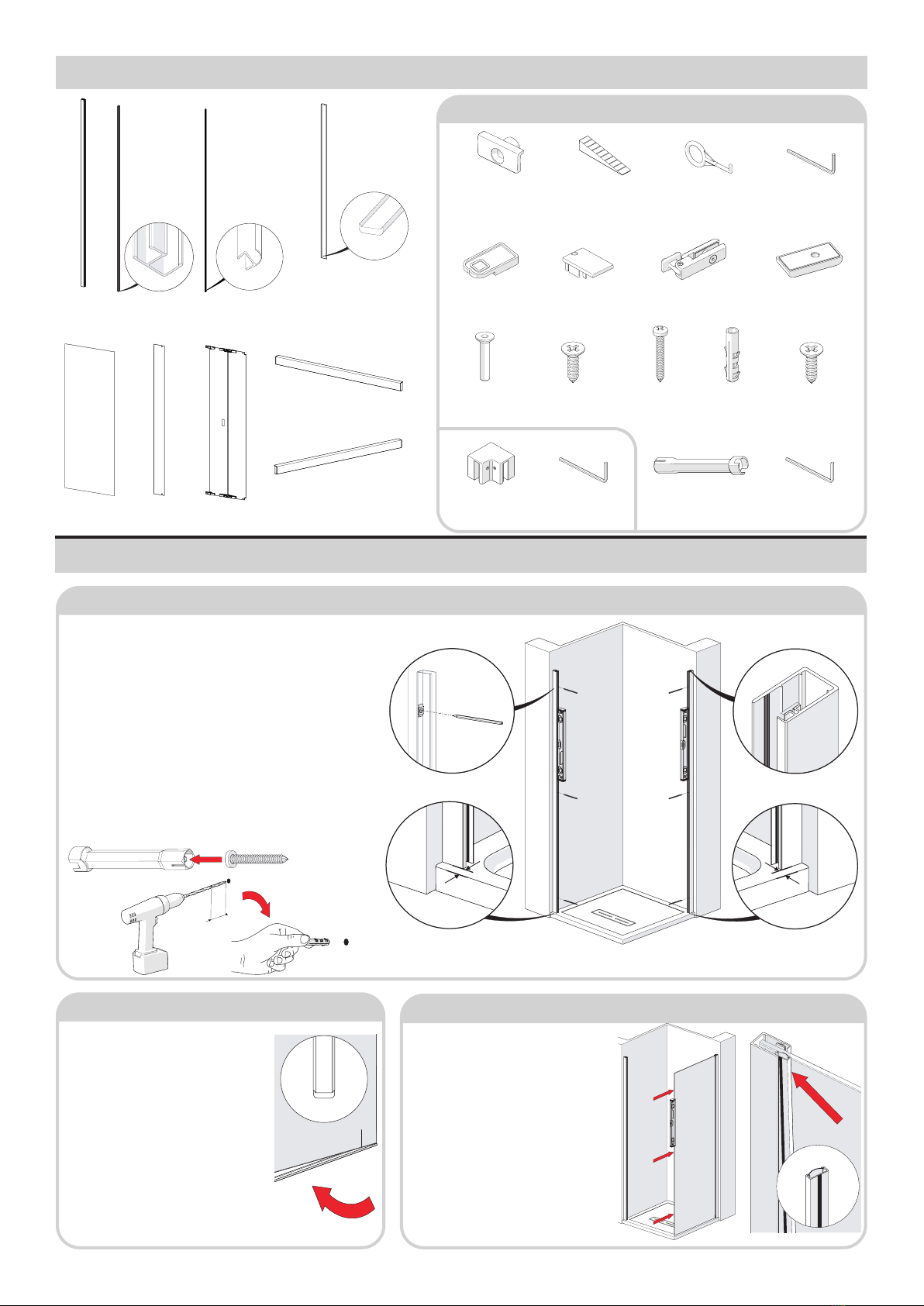

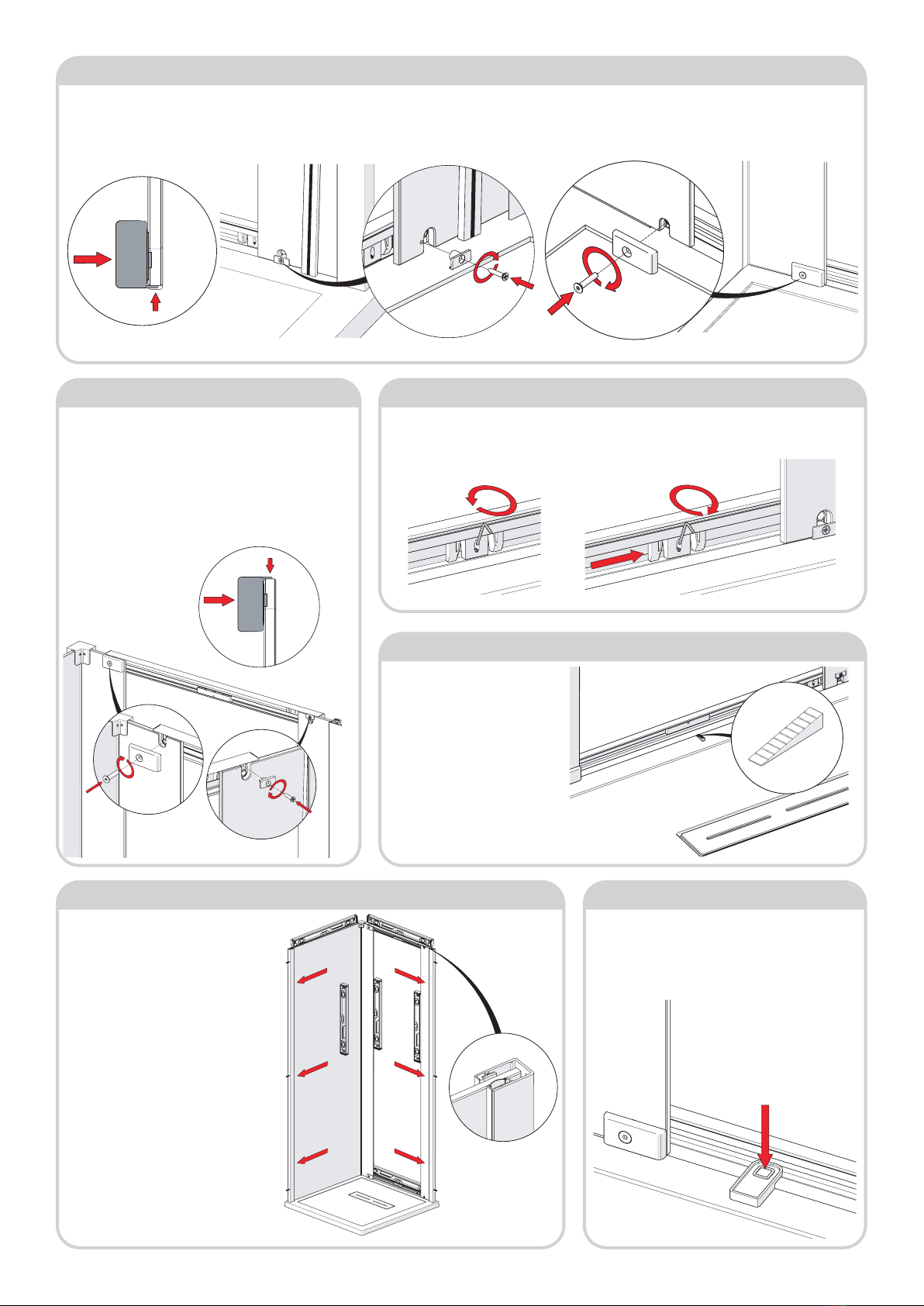

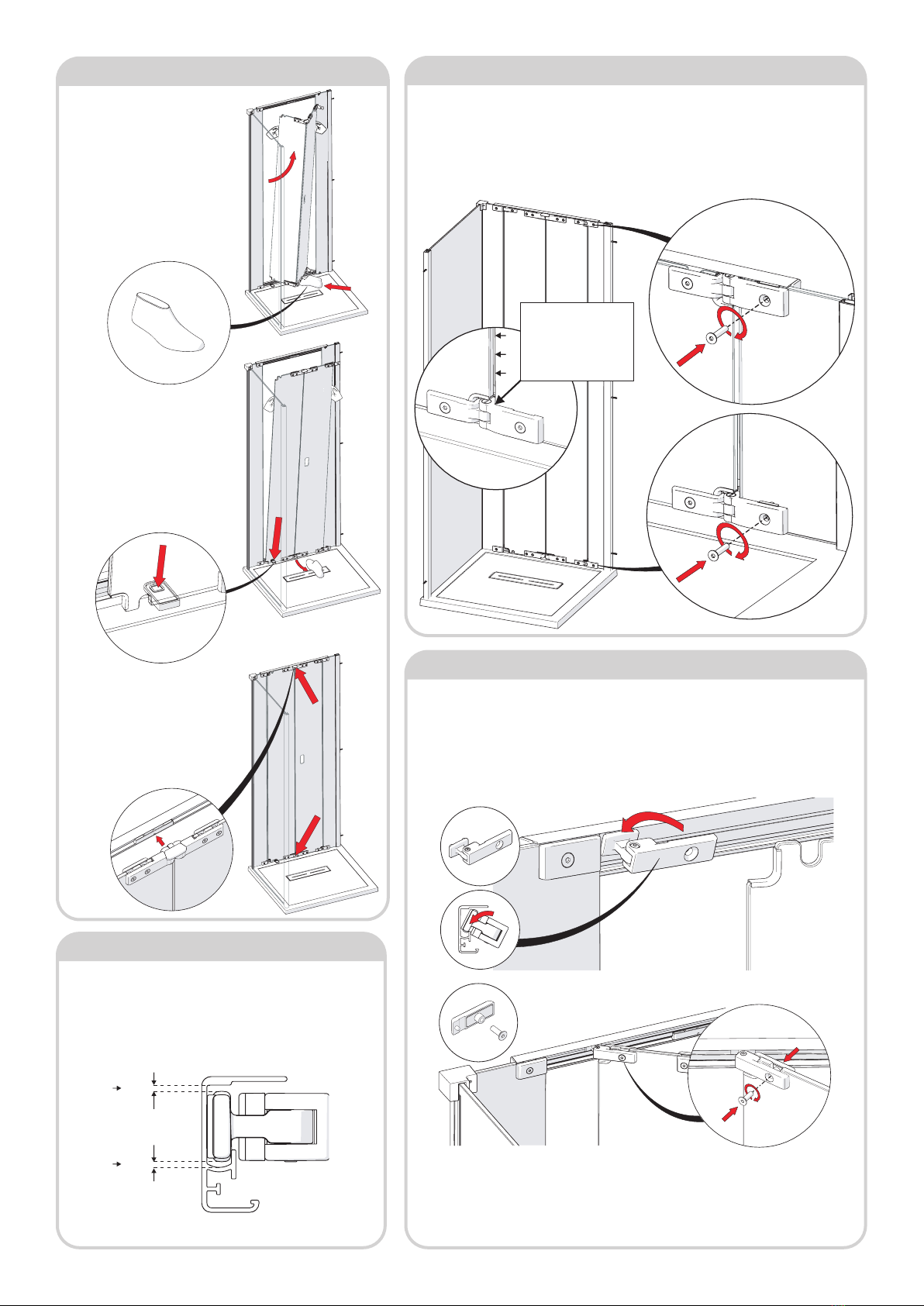

Step 8 - Fit Second Panel Glass

1. Like step 4, carefully t glass panel

into slot in wall post, ensuring panel

is parallel to tray edge.

2. Secure Panel using the remaining

Push-in channel. Remove the

protective sleeve on the push-in

channel extrusion. From inside the

enclosure, place the push-in channel

(black strip towards glass) against the

glass. Again don’t need to fully insert.

Insert 1/4 at the top to secure glass

panel whilst installing.

Push-in channel can be removed, if

necessary, by inserting tool (M305-

01) supplied to pull the channel out

at top.

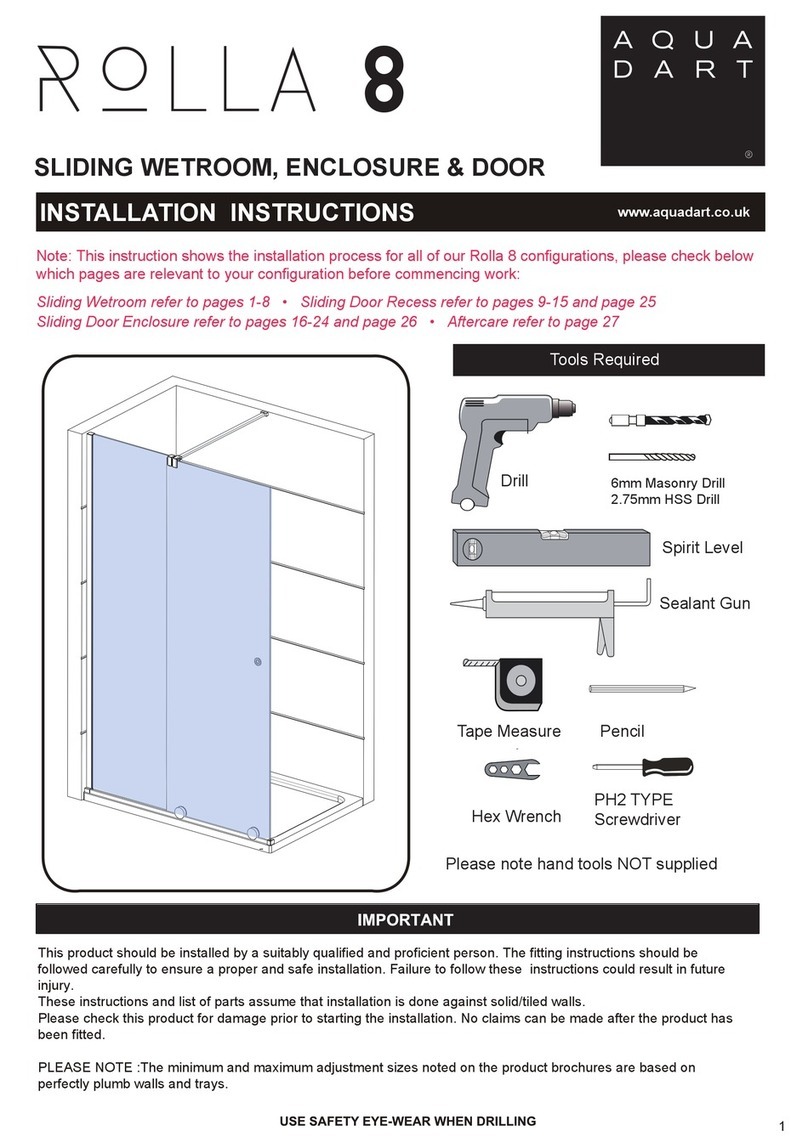

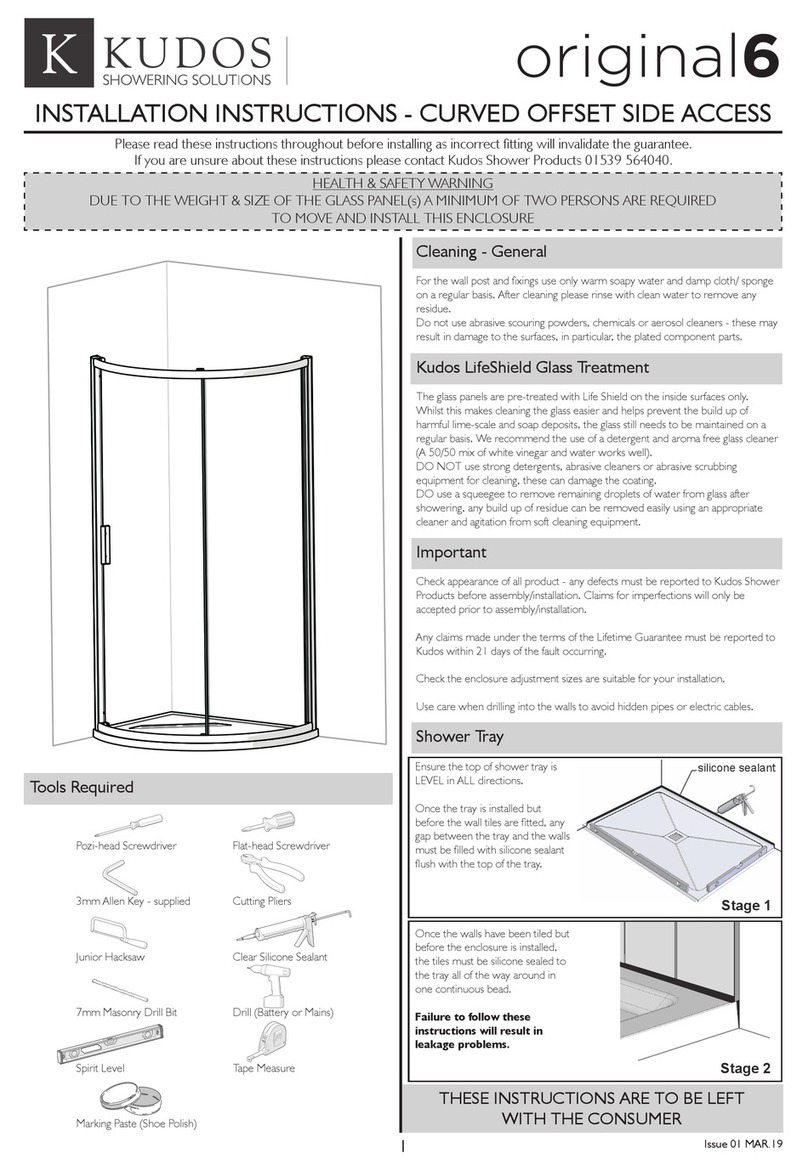

Step 5 - Add Trim to Both Fixed Panels

1. Take note of label on glass ‘This surface to outside’ this will determine which is the bottom

edge of your installation.

2a. For 800 Unit acquire 2 X 73mm Trim Seals.

2b. For 900, 1000 Units acquire 2 X 98mm Trim Seals.

3. Peel off a small length of the bottom trim adhesive tape and apply to bottom of glass panel from

the edge as shown. Continue along length of trim, peeling away the tape as you go, until the full trim

length is adhered to the panel.

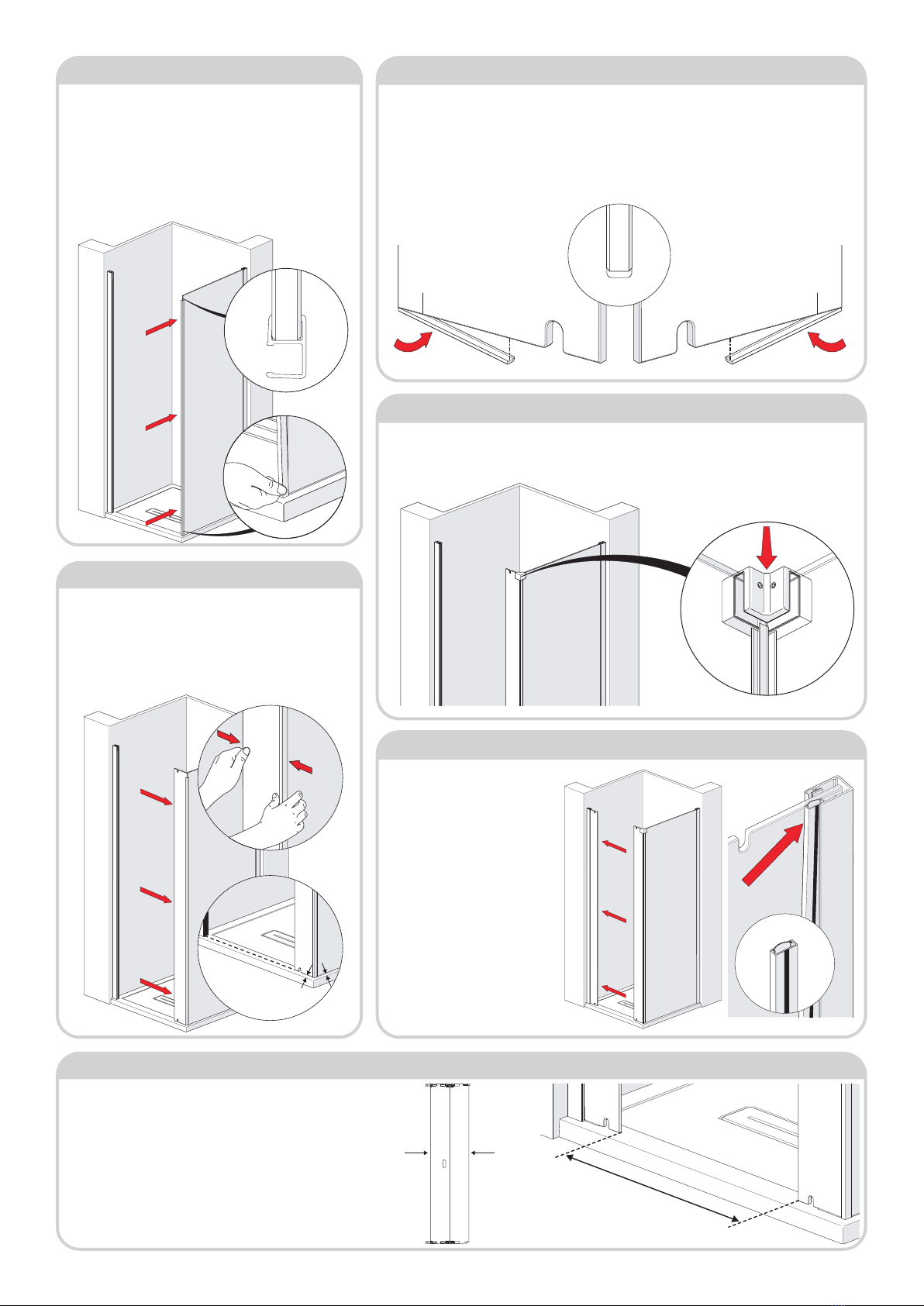

Step 7 - Add Corner Bracket

1. Acquire Corner Bracket (DCM41-01) from the Side Panel Pack. As indicated place this over the

top of the two adjoining glass panels. Use the 3mm Allen key to remove/tighten the grub screws to

the xed panels.

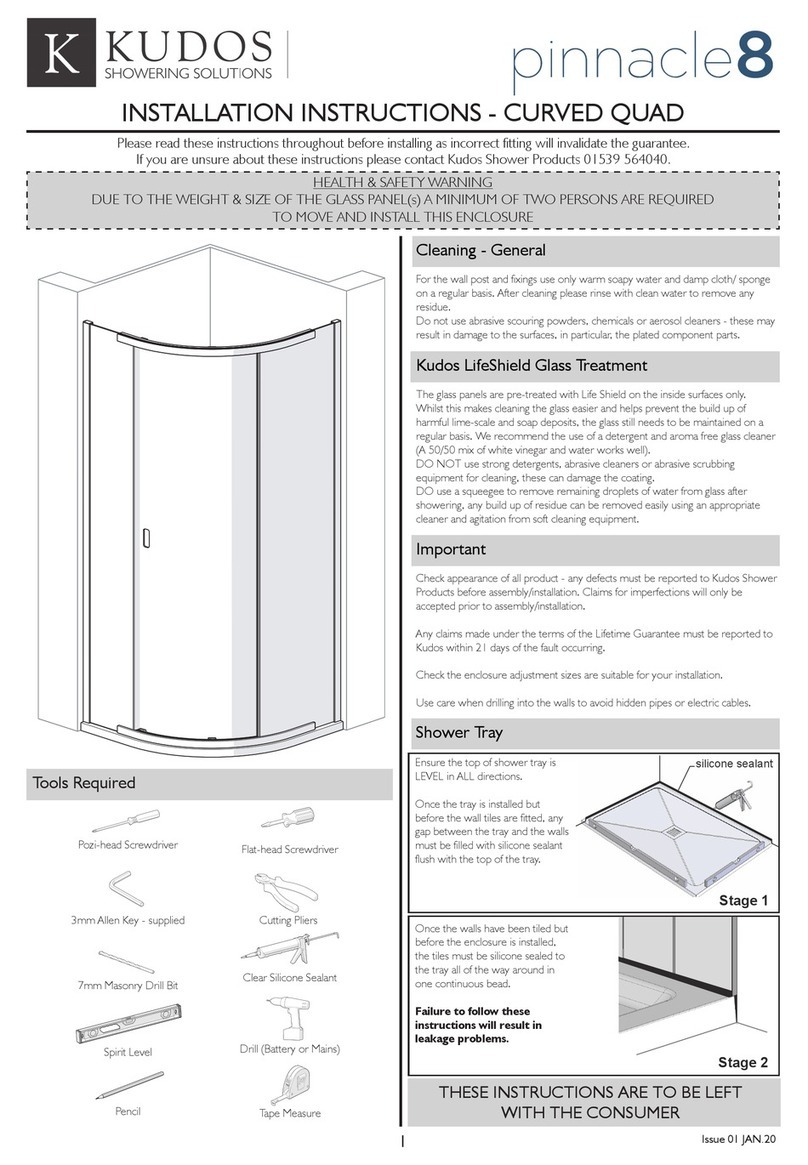

Step 4 - Fit Corner Joint Seal

1. Acquire the PlexRF-018-06 from the Side Panel Pack.

From starting at the bottom, press this over the glass edge

ensuring that it is fully seated over the entire length. Position

as shown. If tight, lubricate corner seal and glass edges with a

damp clean cloth to ease tment - the water will evaporate

over a short period. Do not use silicone spray or any other

substance other than water, these will not fully dry out and

will compromise the grip and rigidity of the joint.

parallel

parallel

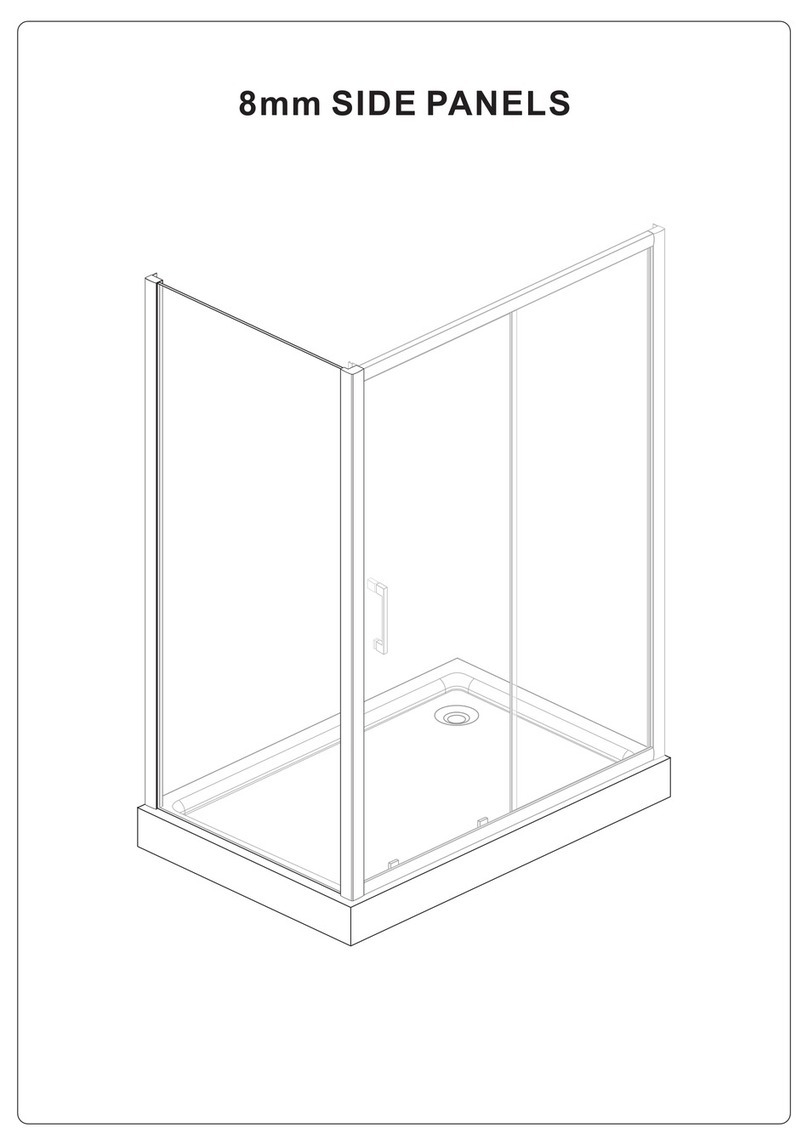

Step 6 - Fit Fixed Panel

1. Add xed panel to the Corner Joint seal, make sure it’s the

correct panel. Starting from the top use both hands push the

xed panel into the seal channel. Make sure the panel is fully

inserted all the way though. Adjust side panel/in-line panel

to ensure side panel is parallel to tray edge and the outside

surface of in-line panel is aligned with the surface of gripper

seal in the adjacent ‘door’ wallpost.

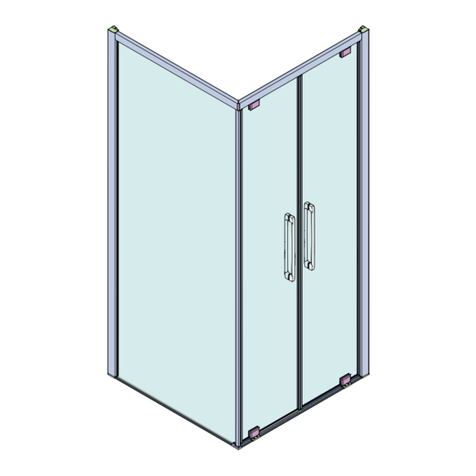

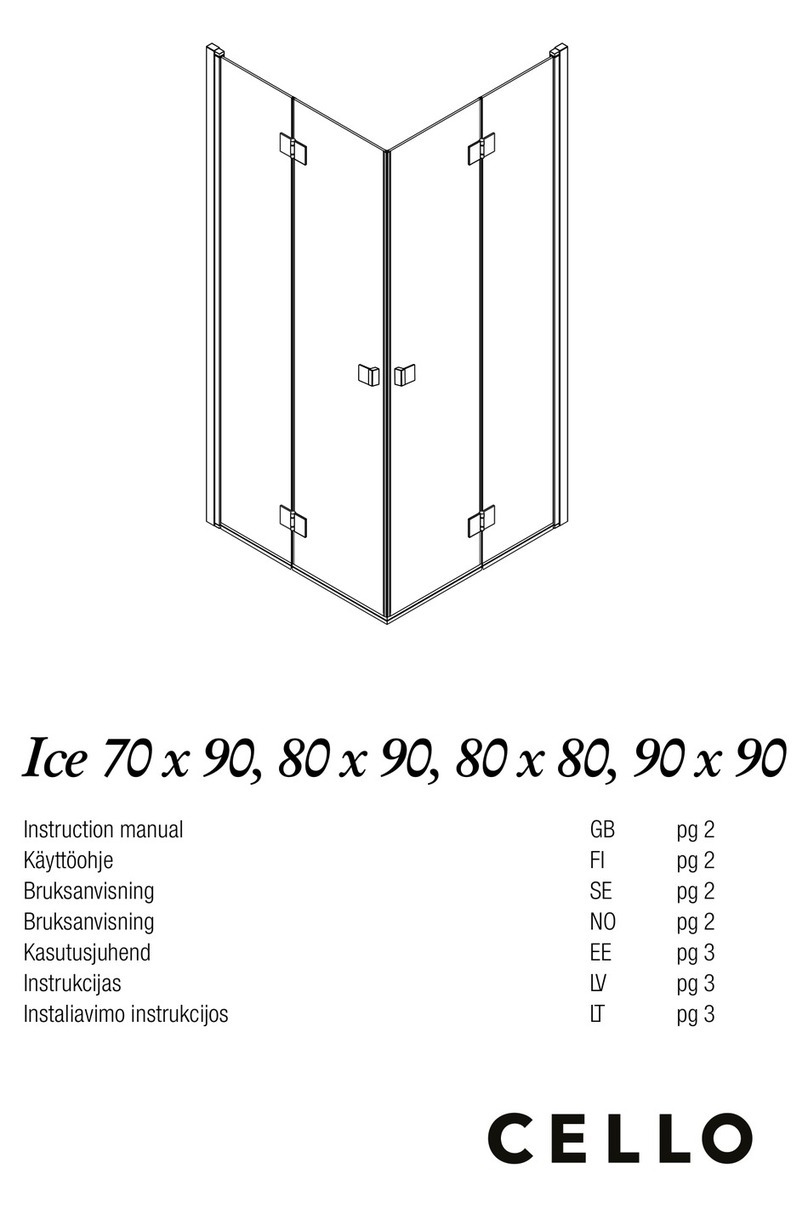

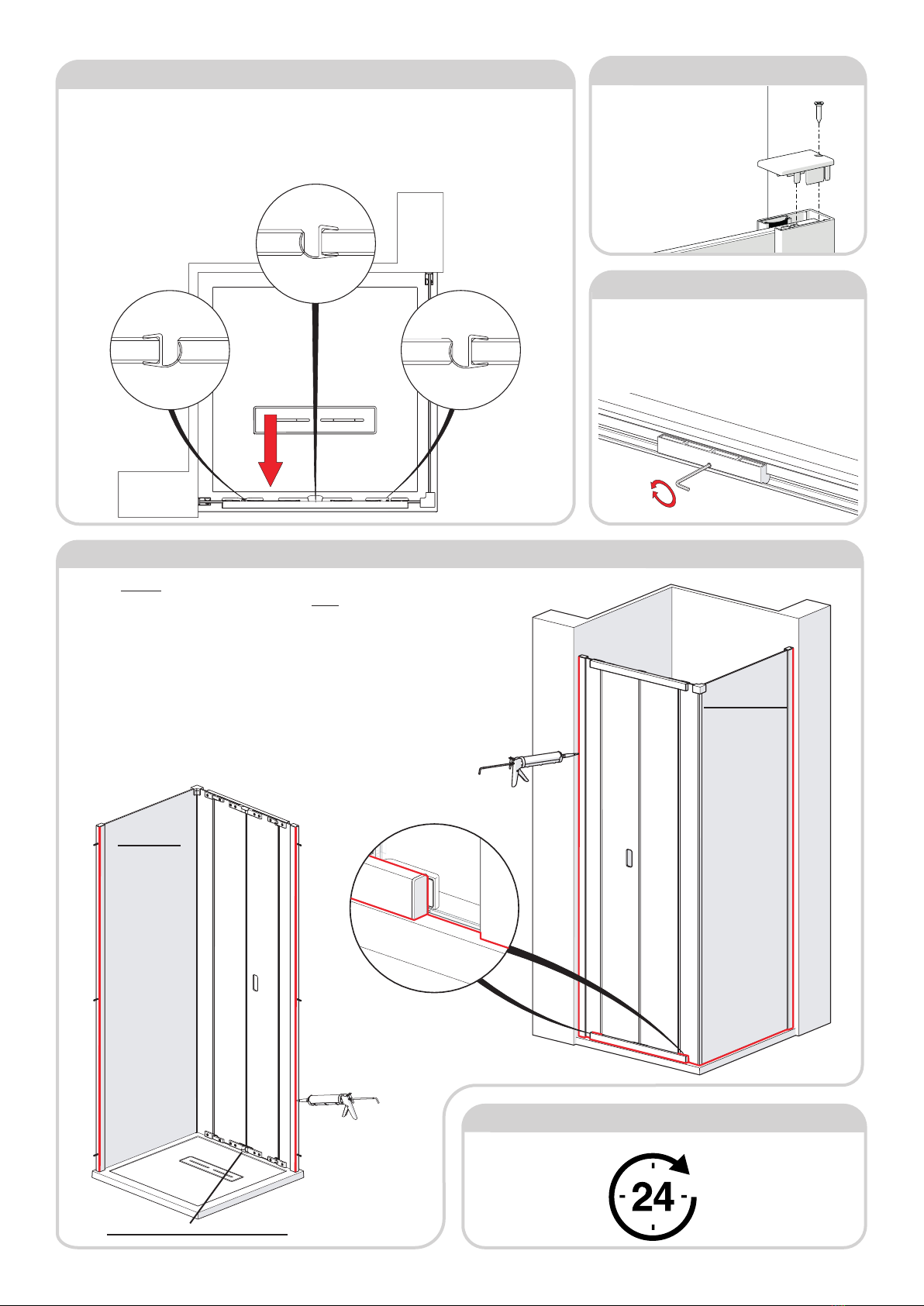

Step 9 - Adjust In-line Glass Panels

Xmm

1. Carefully unpack the folding door assembly pack. Unfold the

panels into a straight line and measure the overall width of the

panels then add 11mm to this to give ’X’ dimension.

For example: folding panel width = 631mm + 11mm =

642mm

2. Adjust the xed panel inserted into the wallpost to achieve

the correct ’X’ dimension between both panels. Will need to

remove and re-insert the push-in channel to achieve this. Use

level to ensure xed panel is vertical.

measure

Inside Outside

Inside view

Inside view