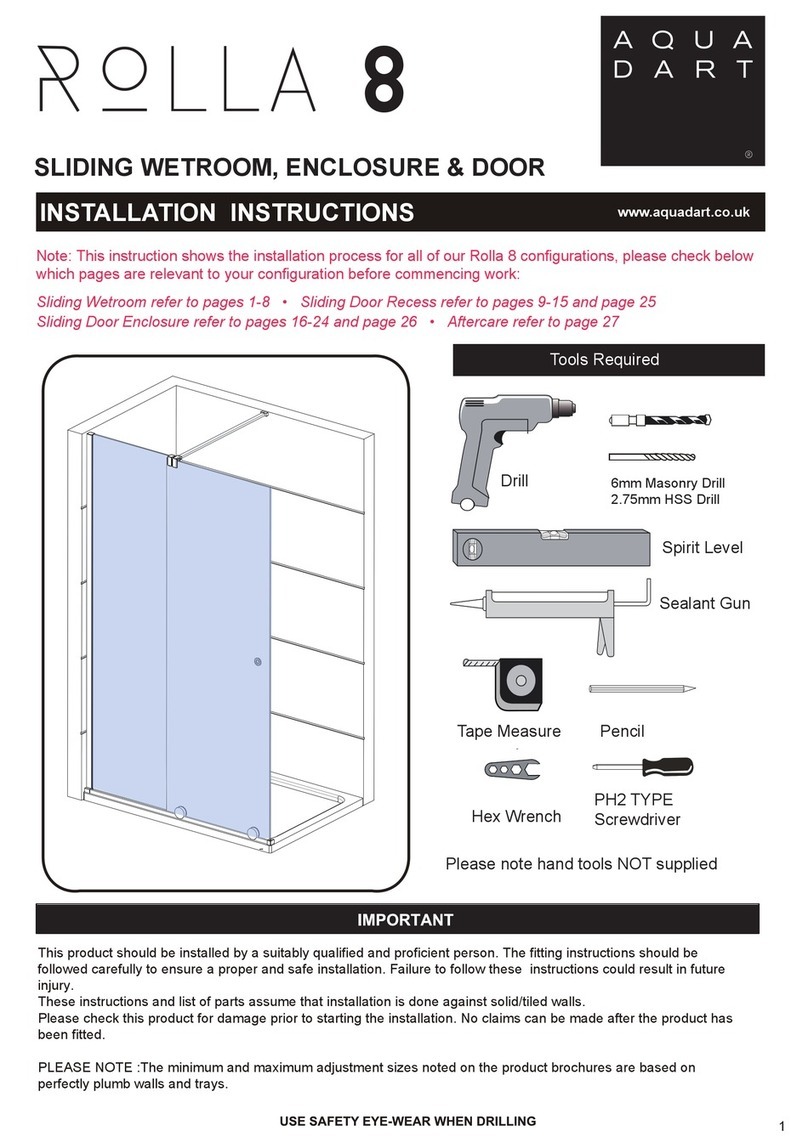

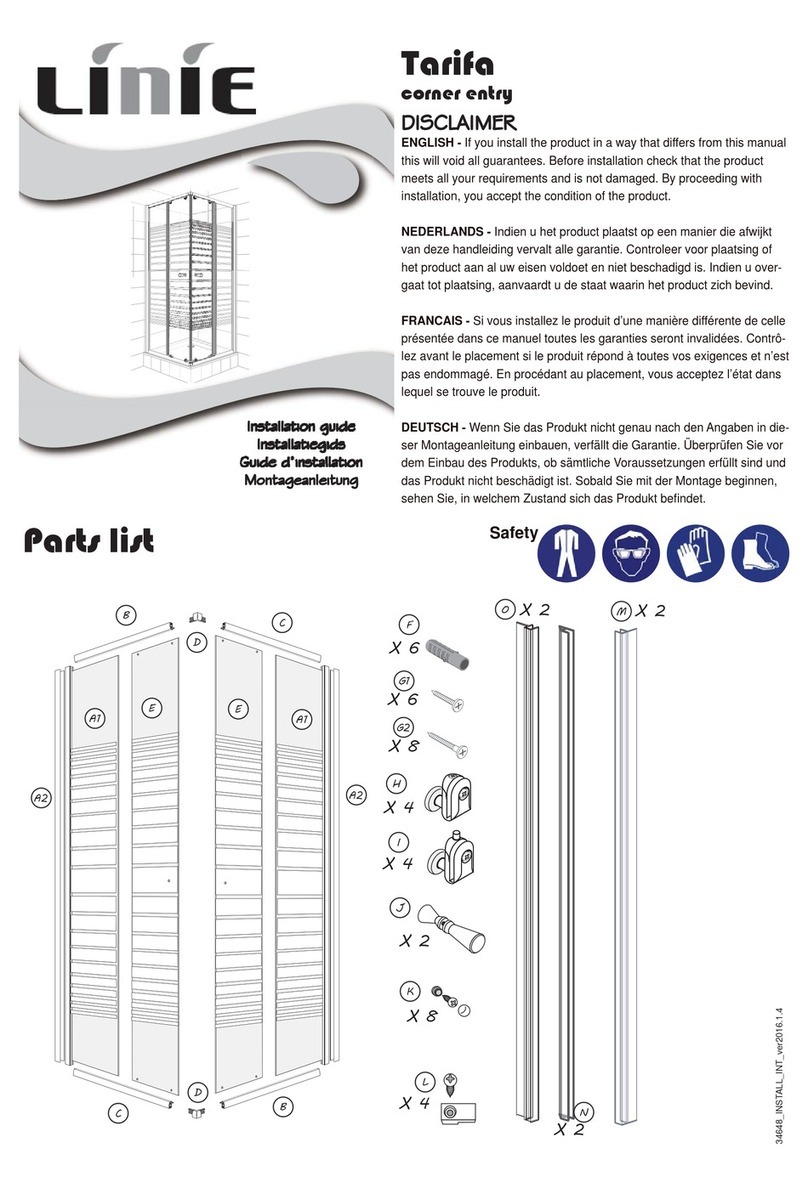

3Issue 01 JAN.20

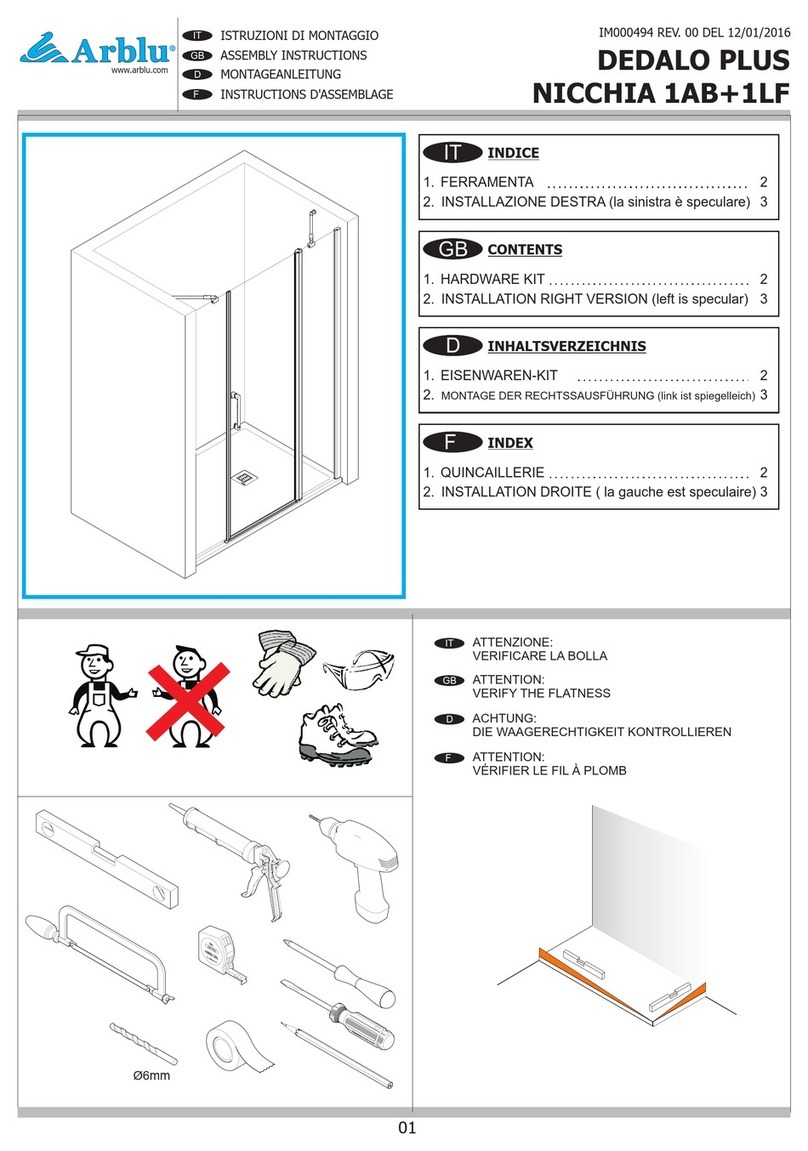

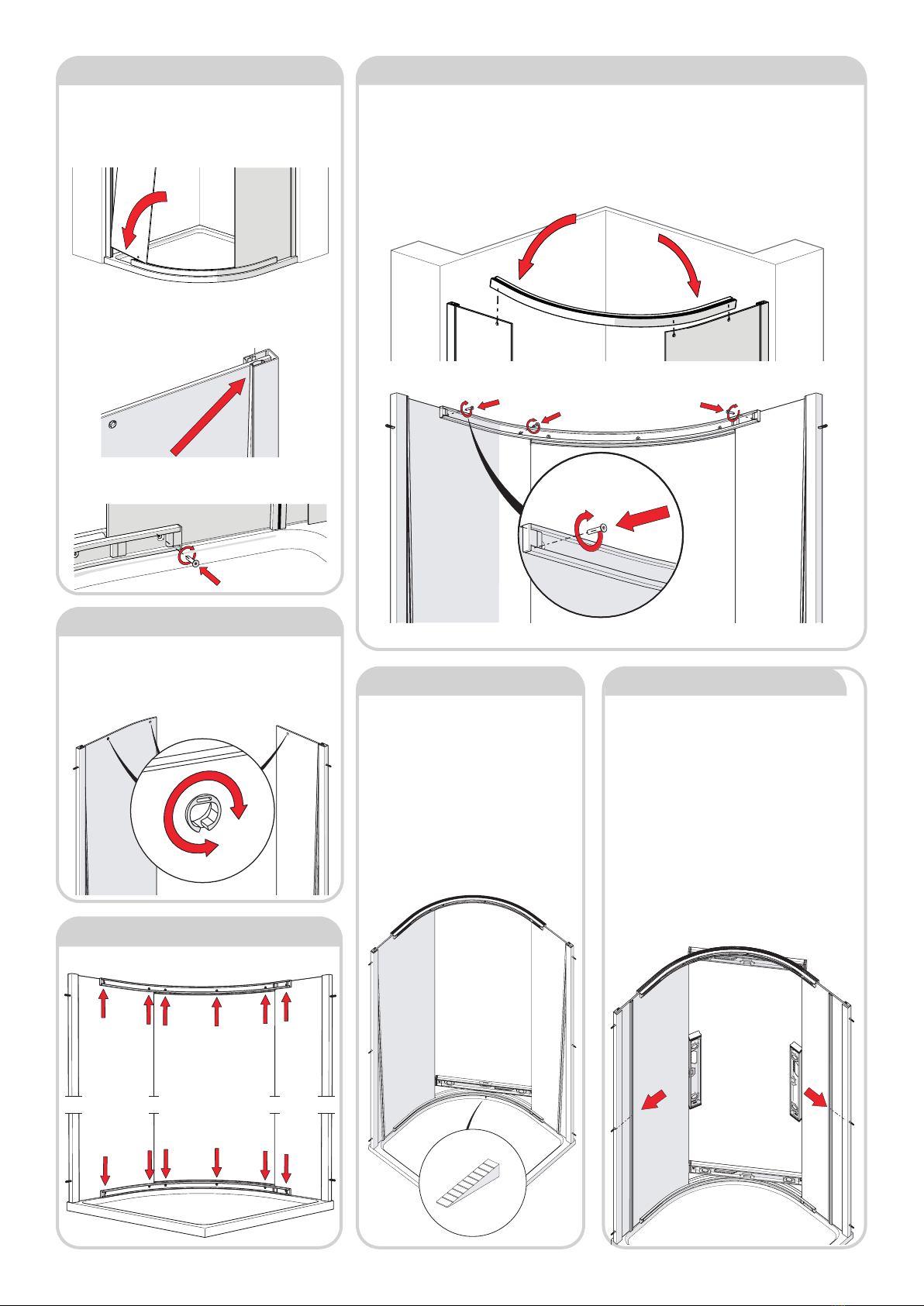

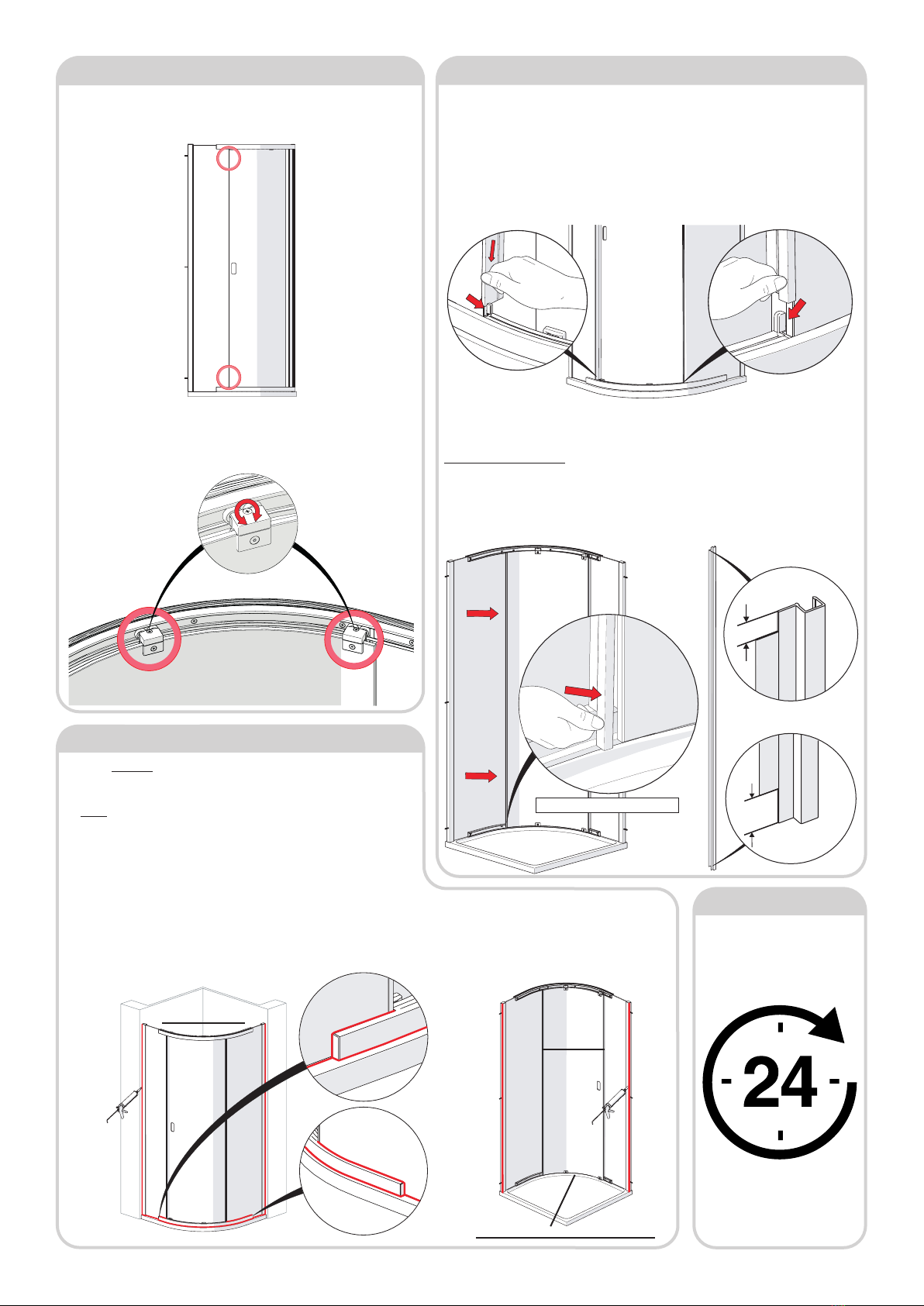

Step 3 - Add Trim to J-Bend Panel

1. Take note of label

on glass ‘This surface

to outside’ this will

determine which is the

bottom edge of your

installation.

2. Use 160mm Trim Seal.

3. Peel off a small length of

the bottom trim adhesive

tape and apply to bottom of

glass panel 15mm from the

end as shown. Continue

along length of trim, peeling

away the tape as you go,

until the full trim length is

adhered to the panel.

15mm

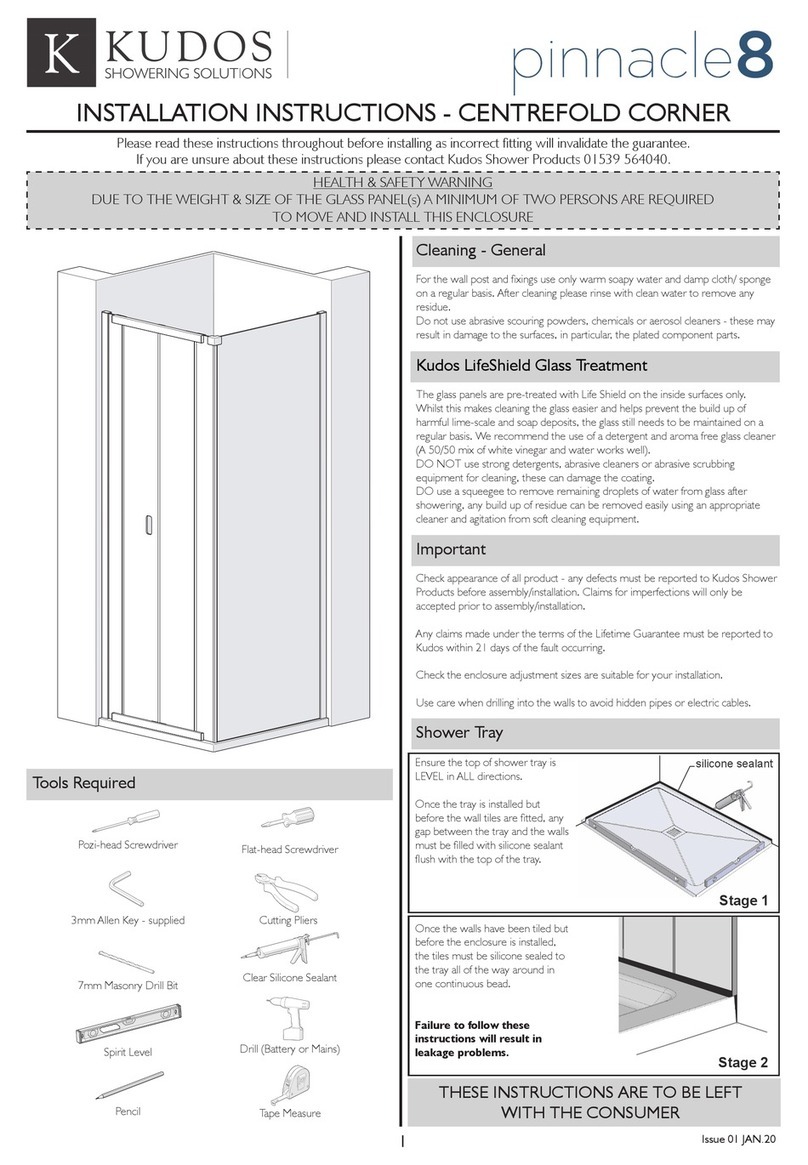

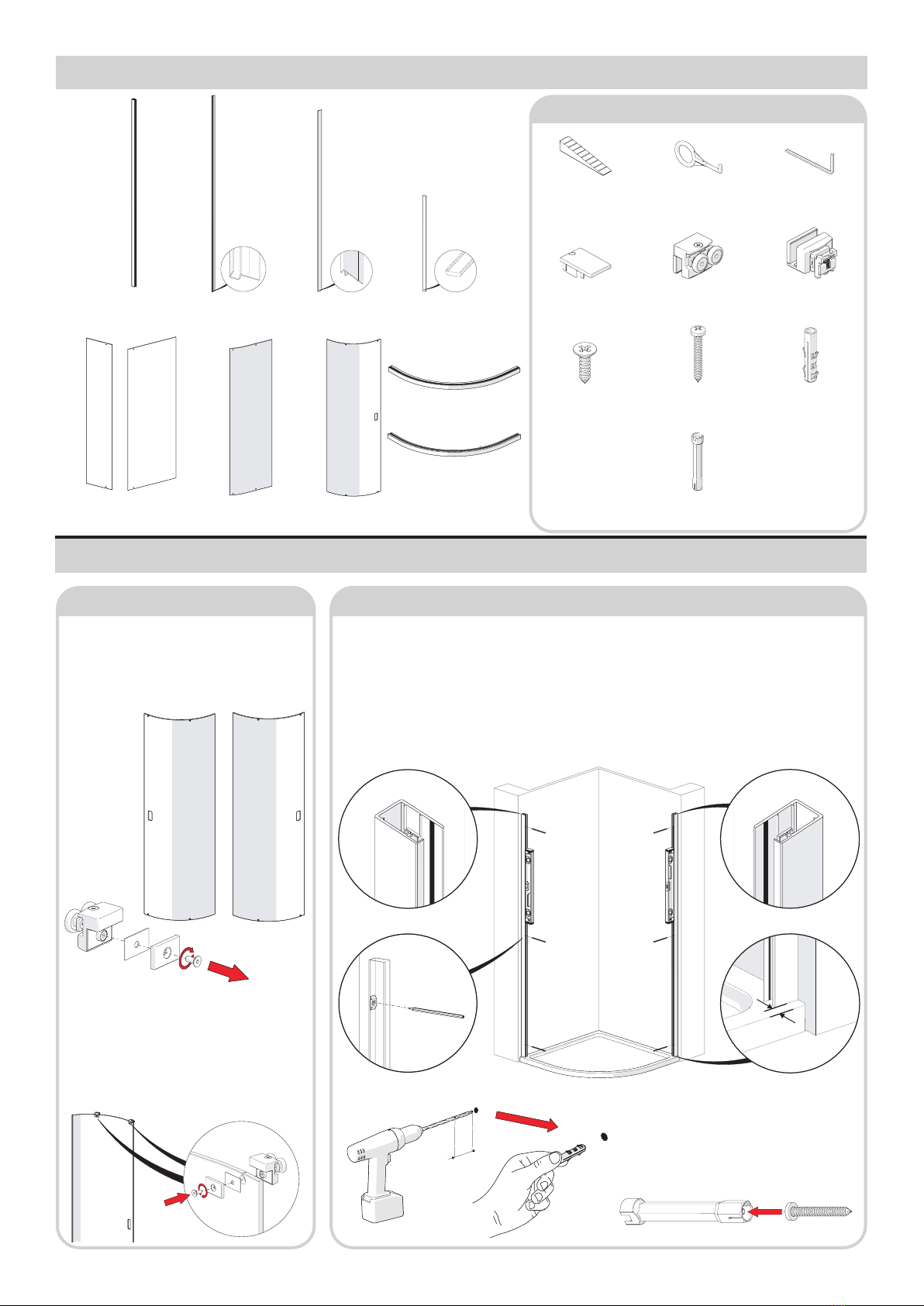

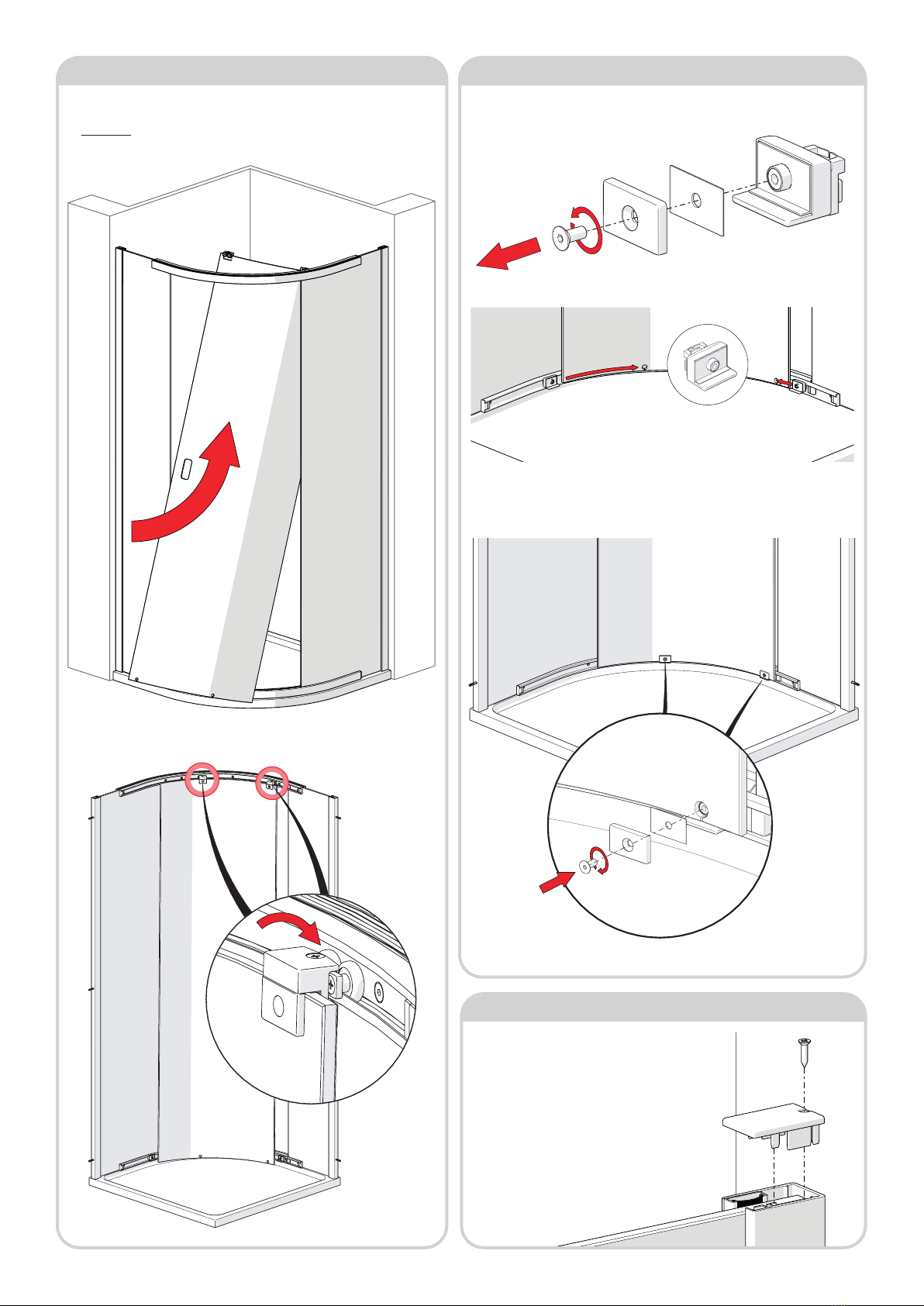

Step 4 - Fit J-Bend Panel Glass and secure Panel using Push-in channel

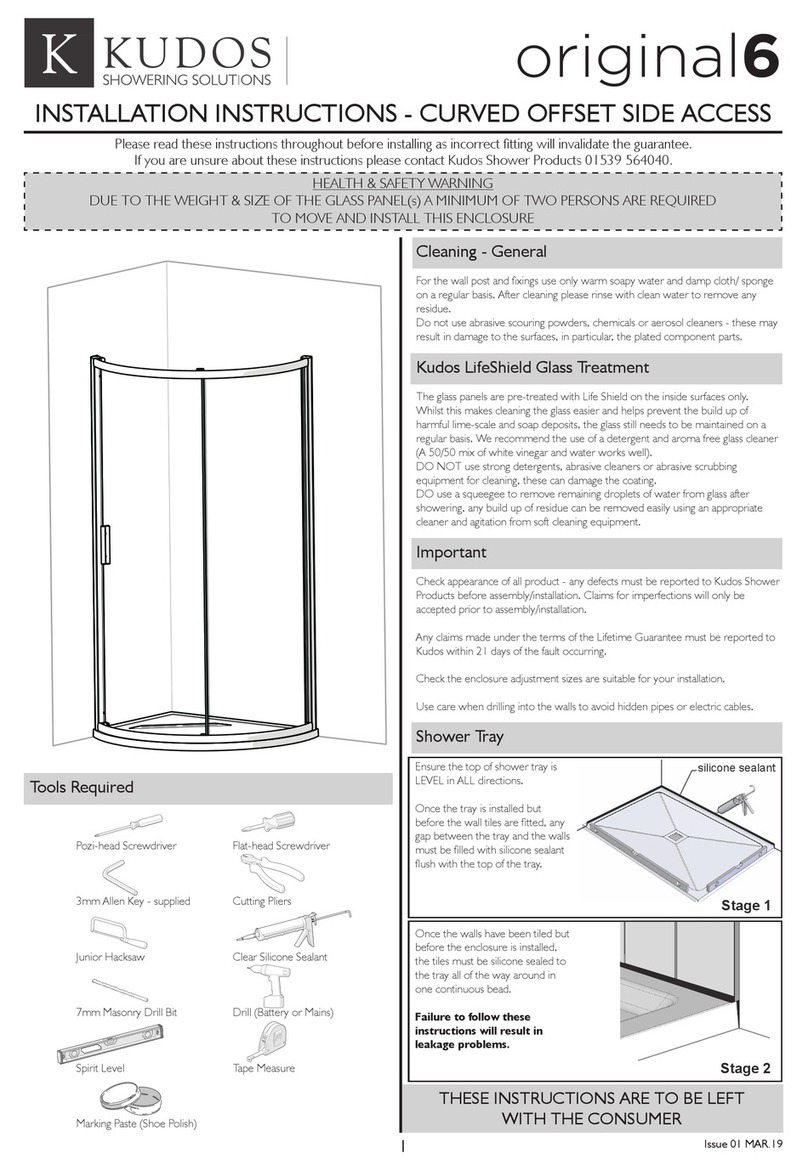

Step 5 - Select Rail for bottom

1. The rails are handed to suit both left hand and right hand

access. Select the correct rail for fitting to bottom.

2. Remove the three screws that fix the inner and outer extrusion,

as shown below.

3. Very lightly loosen the mid-rail outer screws, as shown below.

Do not remove, or loosen too much that the screws could self

remove.

Step 6 - Fit Bottom Rail to J-Bend Panel

1. Carefully slide the dis-assembled rail from step 5

underneath and along the glass panel until the mid-rail

endcaps abuts the glass panel edge. Line up the 2 holes

on the rail with 2 holes on the glass. Be careful not to

dislodge any glass patches on the rail with the J-Bend

Panel glass edge.

15mm

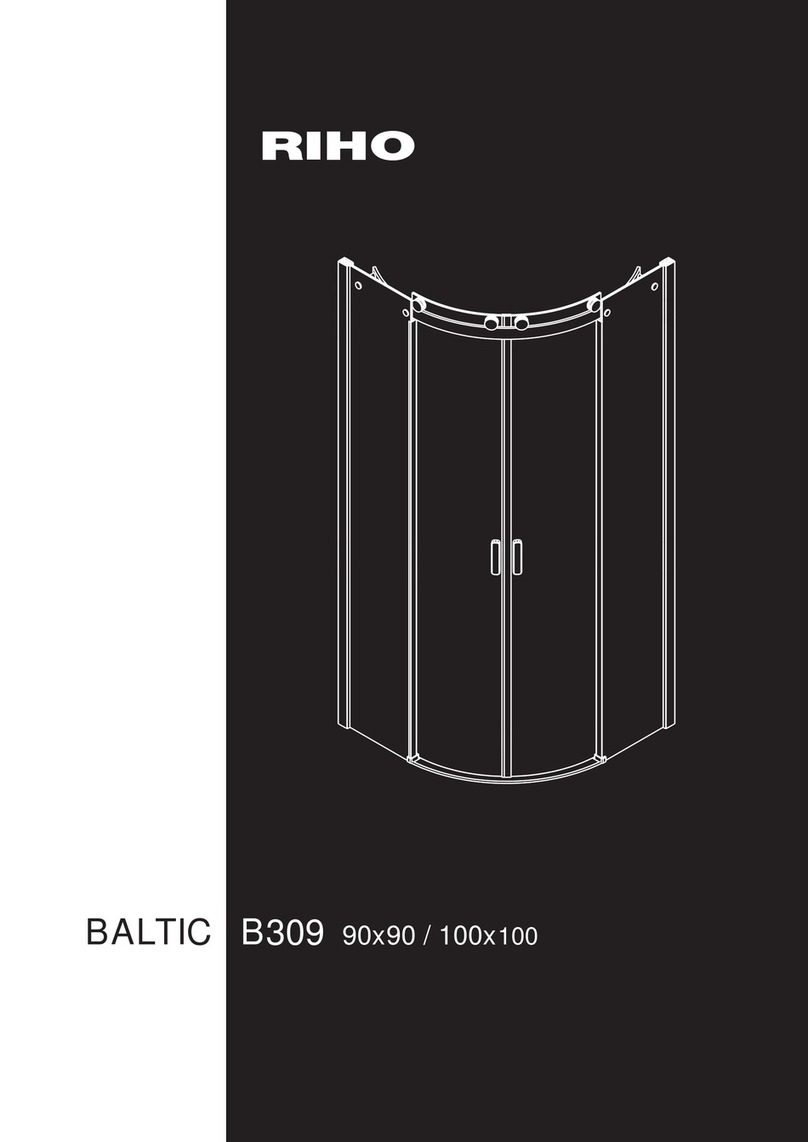

Step 7 - Add Trim to Fixed Panel

1. Take note of label on glass ‘This surface to

outside’ this will determine which is the bottom

edge of your installation.

2. Use 210mm (for 900x900 unit) / 510mm (for

1200x900 unit) Trim Seal depending on which Unit

you’re installing.

3. Like step 3, peel off a small length of the bottom

trim adhesive tape and apply to bottom of glass

panel 15mm from the end as shown. Continue

along length of trim, peeling away the tape as you

go, until the full trim length is adhered to the panel.

3. Lightly re-insert 2 of the 3 screws removed

previously, as shown below from the inside. Do not

fully tighten.

Step 8 - Prepare Top Rail

1. Remove the three screws that fix the inner and outer extrusion, as shown below.

2. Very lightly loosen the mid-rail outer screws, as shown below. Do not remove, or loosen too much

that the screws could self remove.

Push-in channel can be

removed, if necessary, by

inserting tool (M305-01)

supplied to pull the channel

out at top.

Add from

inside

Remove from

inside

Inside view

Inside view

1. Carefully fit glass panel fully into slot in wallpost,

ensuring panel is parallel to tray edge.

2. Acquire the shim from the installation back. Place the

shim under the glass so that there is approx. 3-4mm gap

underneath the glass panel. Make sure the shim isn’t in

contact with the Trim seal from step 3. See below.

3. From inside the enclosure, place the push-in channel

(black strip towards glass) against the glass. At this stage

don’t need to fully insert. Insert 1/4 at the top to secure

glass panel whilst installing.

4. Now remove the shim as the push-in channel will

hold the glass in position.

2. Remove push-in channel using the M305-01

provided. So that the J-Bend panel sits on the rail.

4. Re-insert push-in channel, like step 4.