4

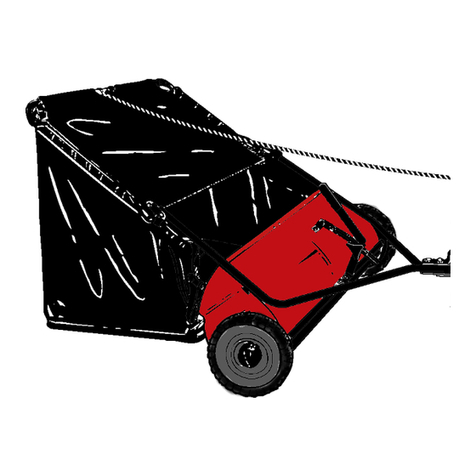

ush-buttons: Opening of container ........................................................................................................... 28

ush-buttons:Move container upwards ...................................................................................................... 28

ush-buttons: ick-Up .................................................................................................................................... 29

Settings of buttons during individual actions ............................................................................................. 30

Move container upwards .............................................................................................................................. 30

Opening of container..................................................................................................................................... 31

Closing of container ....................................................................................................................................... 31

Moving container downwards ...................................................................................................................... 32

Wear parts ...................................................................................................................................................... 33

Elimination of errors ....................................................................................................................................... 33

Working equipment ................................................................................... 34

Basic setting of AMM ..................................................................................................................................... 34

Sweeping ick-Up ......................................................................................................................................... 35

Scarifier ick-Up ............................................................................................................................................ 35

Mowing ick-Up ............................................................................................................................................. 35

Replacing working equipment ................................................................. 36

Removal of used ick-Up ............................................................................................................................. 36

Fitting of new ick-Up.................................................................................................................................... 38

Maintenance work .................................................................................... 40

After each use ............................................................................................................................................... 40

After the first 5 operating hours .................................................................................................................... 40

Monthly ........................................................................................................................................................... 40

Yearly .............................................................................................................................................................. 41

......................................................................................................... 41

Retightening chain on rh side, seen in direction of travel ........................................................................ 42