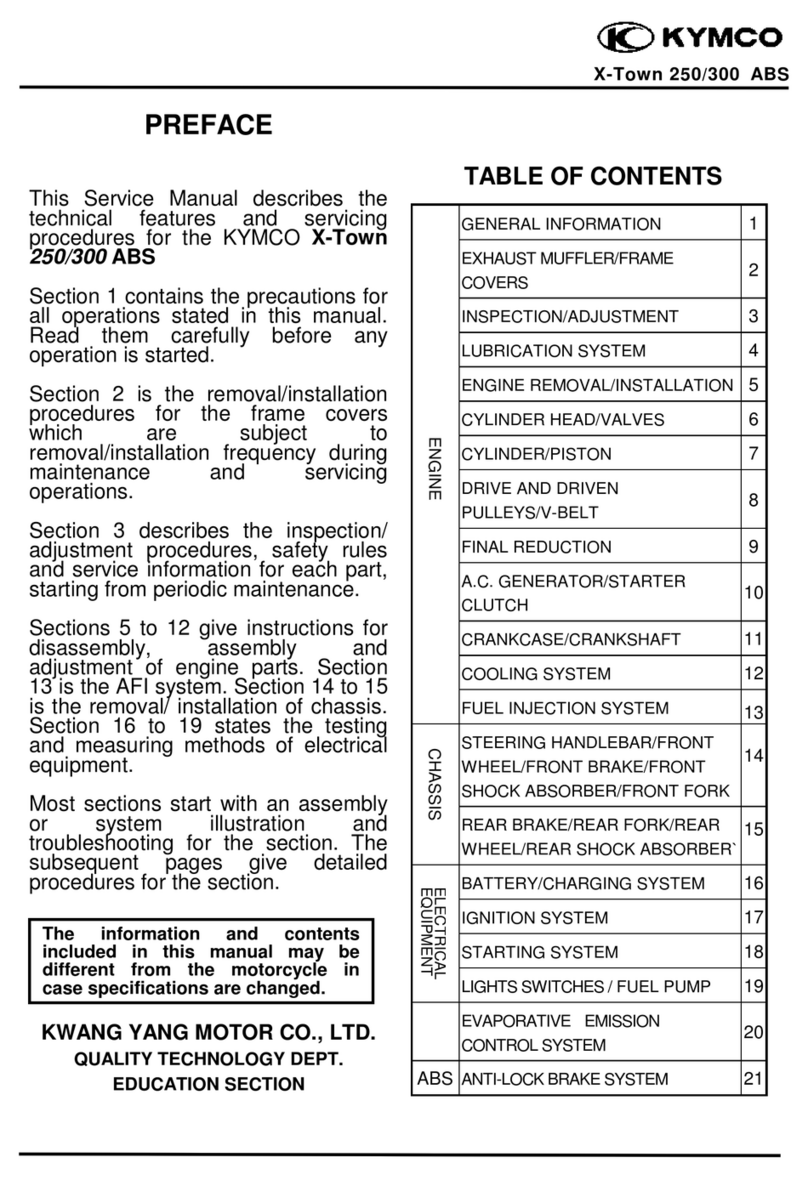

17. IGNITION SYSTEM

17-2

PEOPLE/PEOPLE S 250

SERVICE INFORMATION

GENERAL INSTRUCTIONS

•Check the ignition system according to the sequence specified in the Troubleshooting. (Ö1-28)

•The ignition system adopts ignition unit and the ignition timing cannot be adjusted.

•If the timing is incorrect, inspect the ignition unit and A.C. generator and replace any faulty parts.

Inspect the ignition unit with a ignition unit tester

•Loose connector and poor wire connection are the main causes of faulty ignition system. Check

each connector before operation.

•Use of spark plug with improper heat range is the main cause of poor engine performance.

•The inspections in this section are focused on maximum voltage. The inspection of ignition coil

resistance is also described in this section.

•Inspect the ignition switch according to the continuity table specified in page 19-3.

•Inspect the spark plug referring to Section 3.

•Remove the A.C. generator and pulser coil referring to Section 10.

SPECIFICATIONS Item Standard

Spark plug Standard type NGK DPR7EA9

Spark plug gap 0.7mm

Ignition timing “F” mark

Full advance repeatedly

Primary coil 3.6~4.1Ω

Ignition coil resistance (20

℃)Secondary without plug cap 14KΩ

coil with plug cap 19KΩ

Pulser coil resistance (20℃) 105~110Ω

Exciter coil resistance (20℃)1.8~2.1Ω

Ignition coil primary side max. voltage 14V

Pulser coil max. voltage 1.6V

Exciter coil max. voltage 14V

TESTING INSTRUMENT

Electric tester: YF-3501

TROUBLESHOOTING

No spark at plug Engine starts but turns poorly

•Faulty spark plug •Ignition primary circuit

•Poorly connected, broken or shorted wire —Faulty ignition coil

•Faulty ignition switch —Poorly connected wire or connector

•Faulty ignition coil —Poorly contacted ignition switch

•Faulty ignition unit •Ignition secondary circuit

•Faulty A.C. generator —Faulty ignition coil

—Faulty spark plug

—Faulty high-tension wire

—Poorly insulated plug cap

•Improper ignition timing

—Faulty A.C. generator

—Stator not installed properly

—Faulty ignition unit