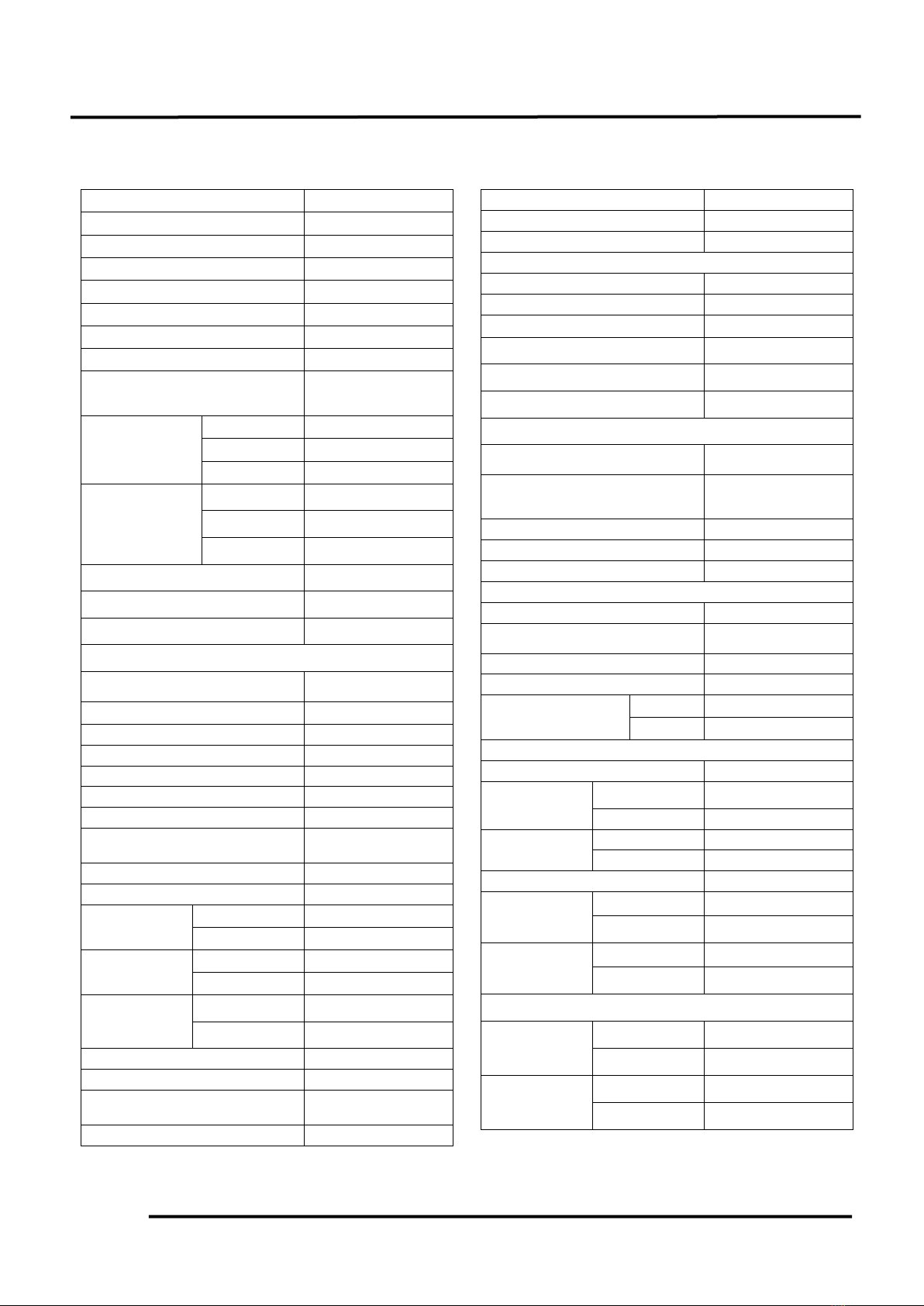

KYMCO X-Town 250 ABS User manual

Other KYMCO Motorcycle manuals

KYMCO

KYMCO Venox 250 User manual

KYMCO

KYMCO Dink-R 150 User manual

KYMCO

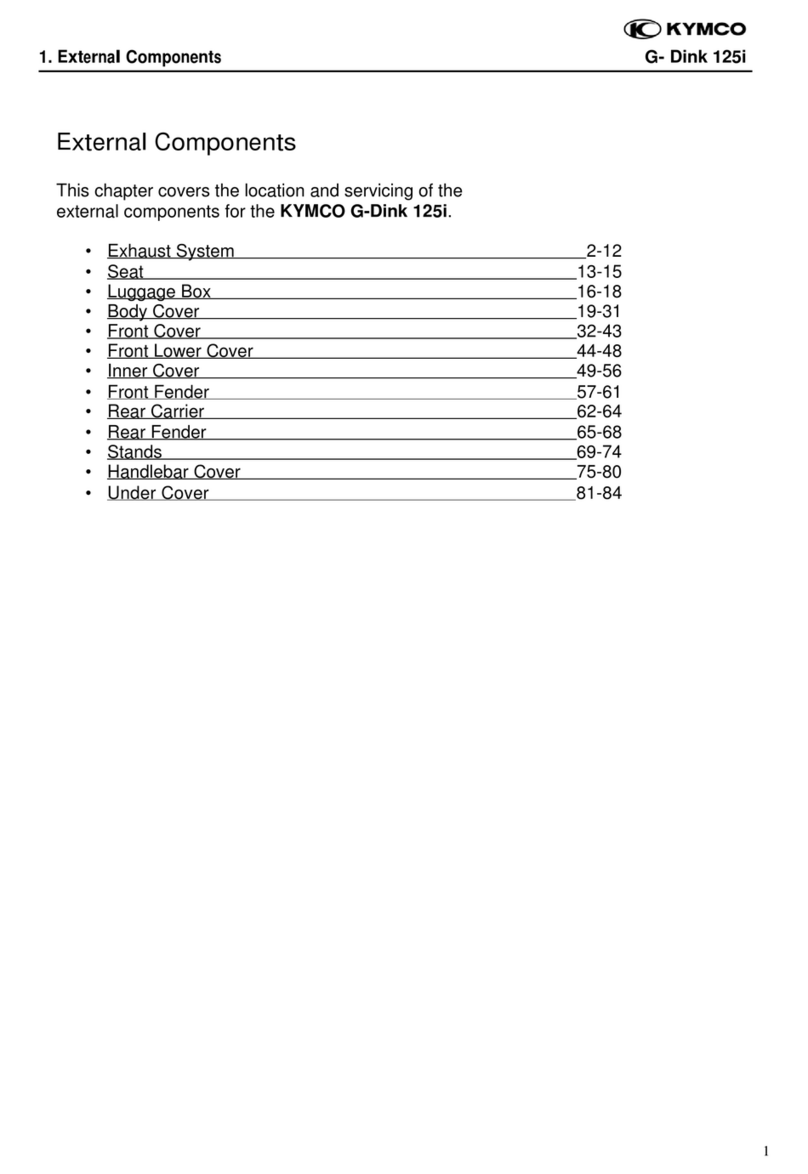

KYMCO G-Dink 125i User manual

KYMCO

KYMCO XCITING 500 User manual

KYMCO

KYMCO AGILITY300 User manual

KYMCO

KYMCO X-Town 300 User manual

KYMCO

KYMCO People S 250 User manual

KYMCO

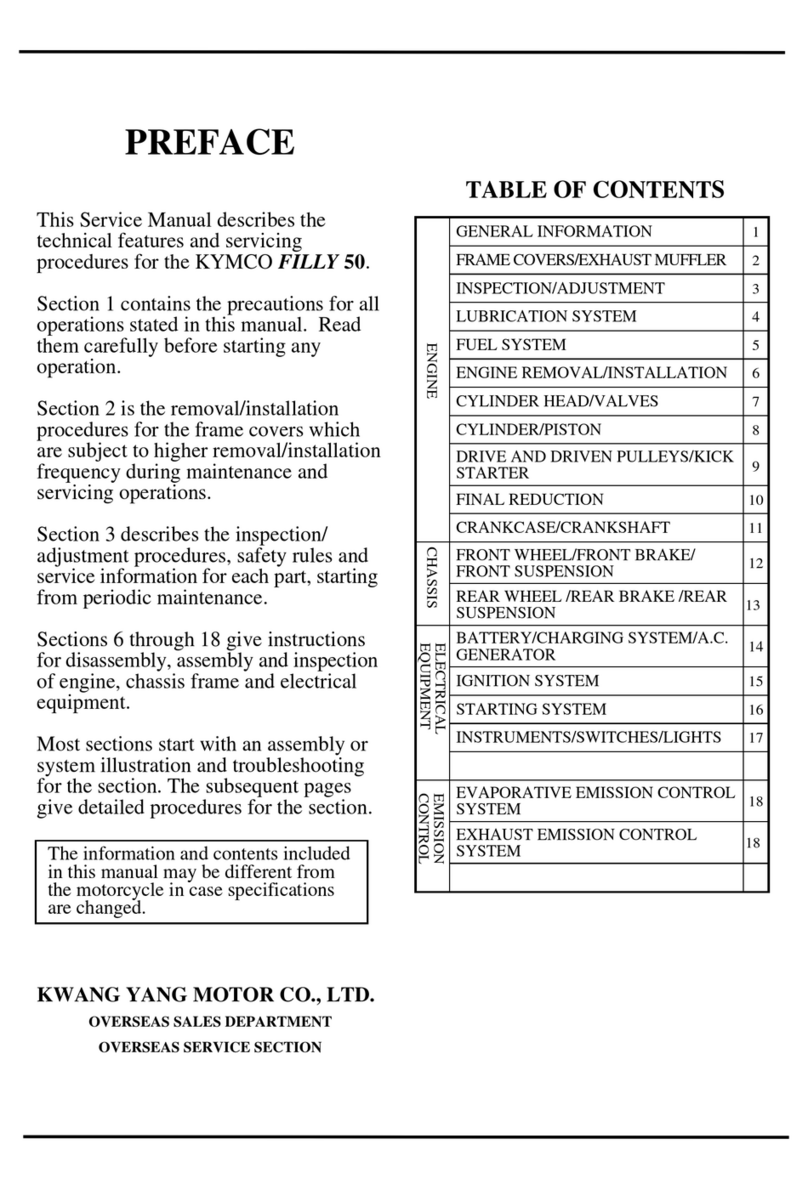

KYMCO FILLY 50 User manual

KYMCO

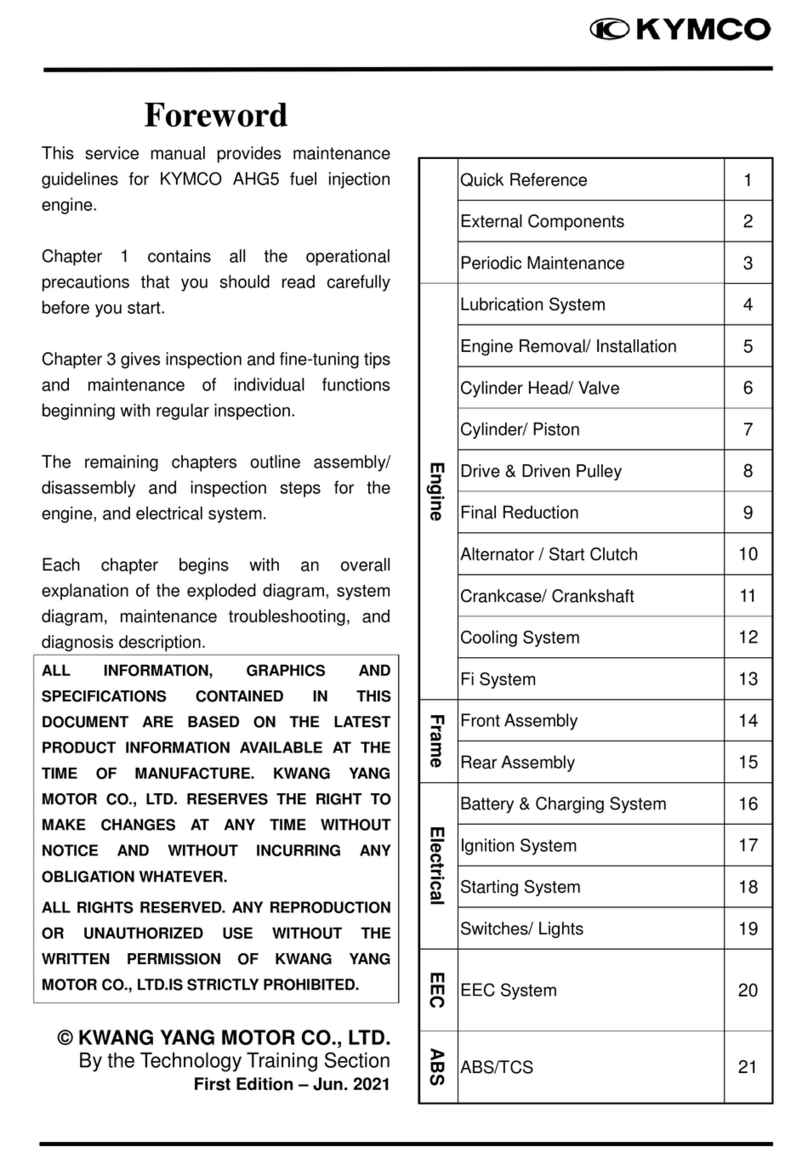

KYMCO AHG5 User manual

KYMCO

KYMCO Dink 50 User manual

KYMCO

KYMCO downtown 300i User manual

KYMCO

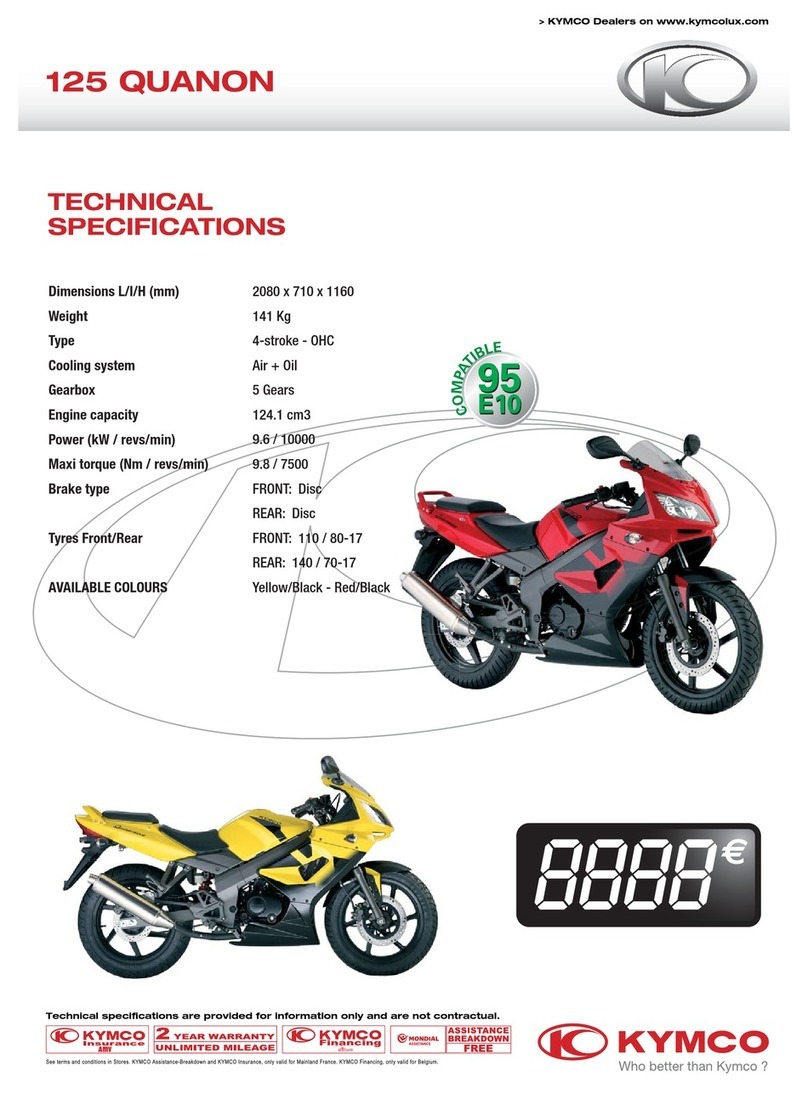

KYMCO Quannon 125 Release note

KYMCO

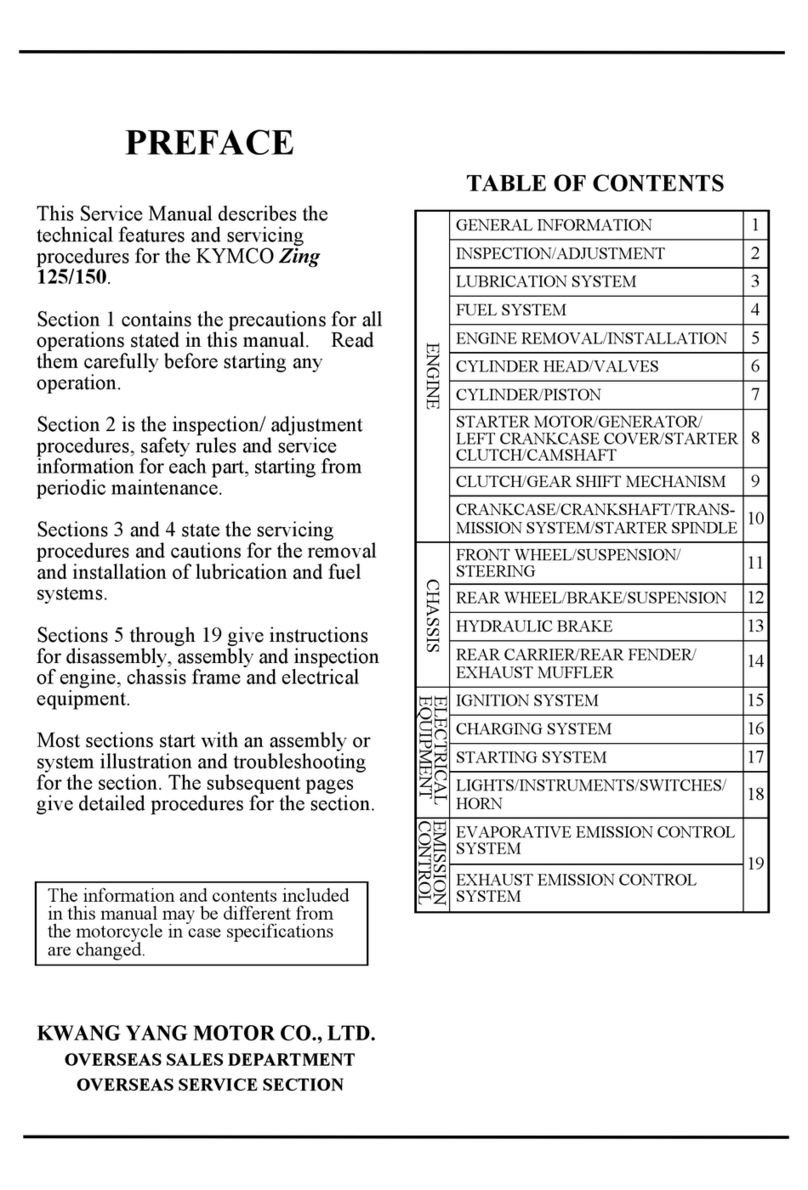

KYMCO 125 ZING II QE - User manual

KYMCO

KYMCO CV3 Series User manual

KYMCO

KYMCO Stryker 125 User manual

KYMCO

KYMCO Dink 50 Release note

KYMCO

KYMCO K-PIPE 125 User manual

KYMCO

KYMCO X-Town CT125 User manual

KYMCO

KYMCO 125 QUANON User manual

KYMCO

KYMCO MXU 300 - User manual