Downtown 300i ABS

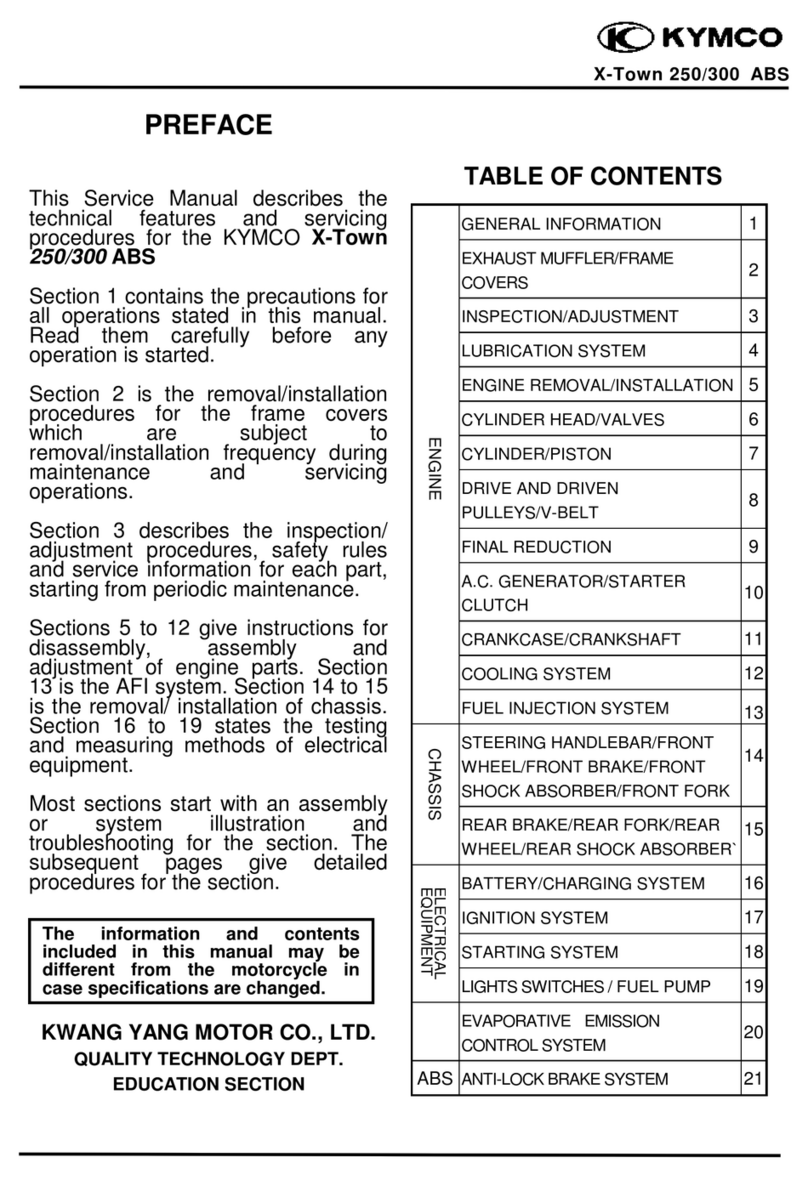

PREFACE

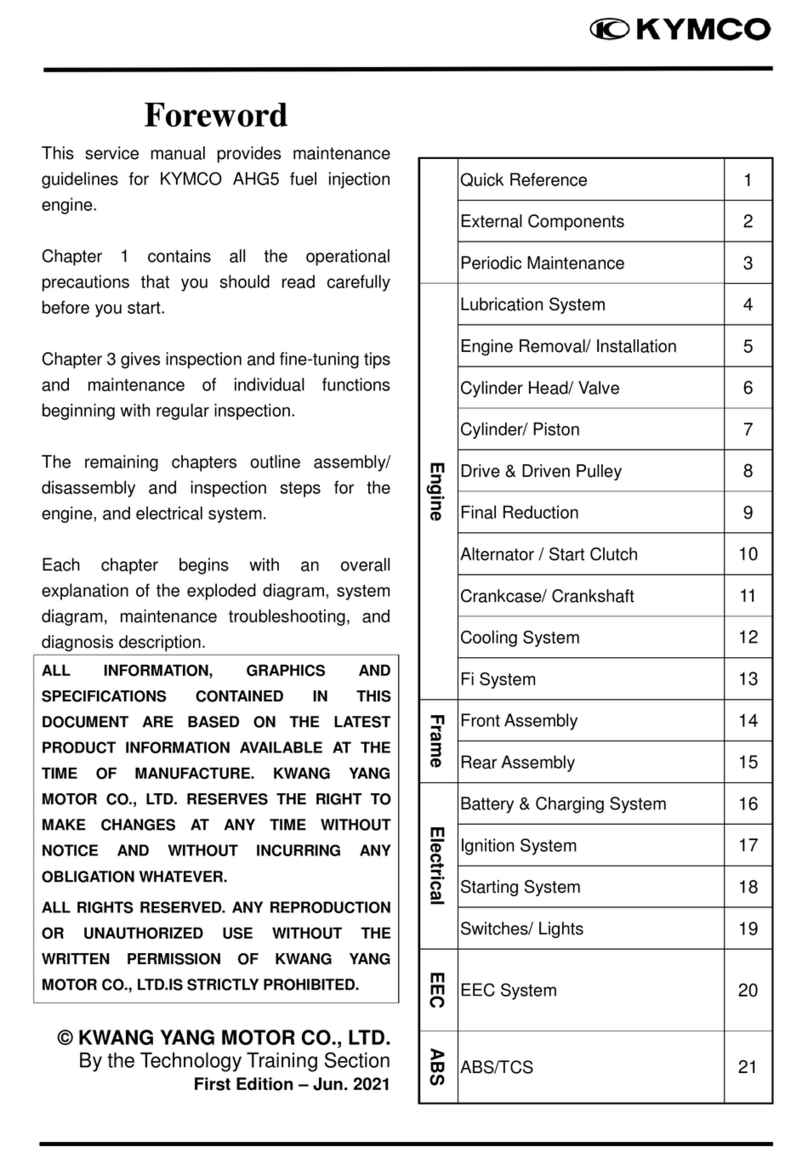

This Service Manual describes the

technical features and servicing

procedures for the KYMCO

Downtown 300i ABS

Section 1 contains the precautions for

all operations stated in this manual.

Read them carefully before any

operation is started.

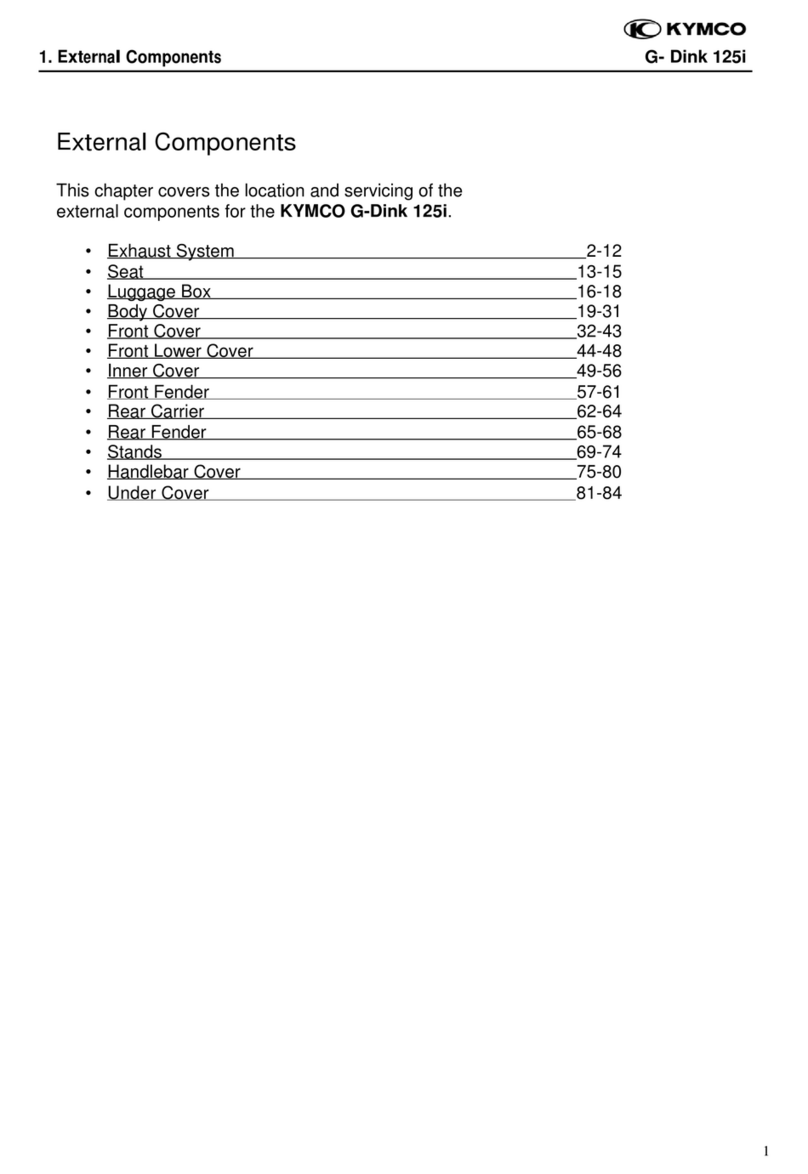

Section 2 is the removal/installation

procedures for the frame covers which

are subject to removal/installation

frequency during maintenance and

servicing operations.

Section 3 describes the inspection/

adjustment procedures, safety rules

and service information for each part,

starting from periodic maintenance.

Sections 5 to 12 give instructions for

disassembly, assembly and

adjustment of engine parts. Section 13

is the AFI system. Section 14 to 15 is

the removal/ installation of chassis.

Section 16 to 19 states the testing and

measuring methods of electrical

equipment.

Most sections start with an assembly

or system illustration and

troubleshooting for the section. The

subsequent pages give detailed

procedures for the section.

KWANG YANG MOTOR CO., LTD.

QUALITY TECHNOLOGY DEPT.

EDUCATION SECTION

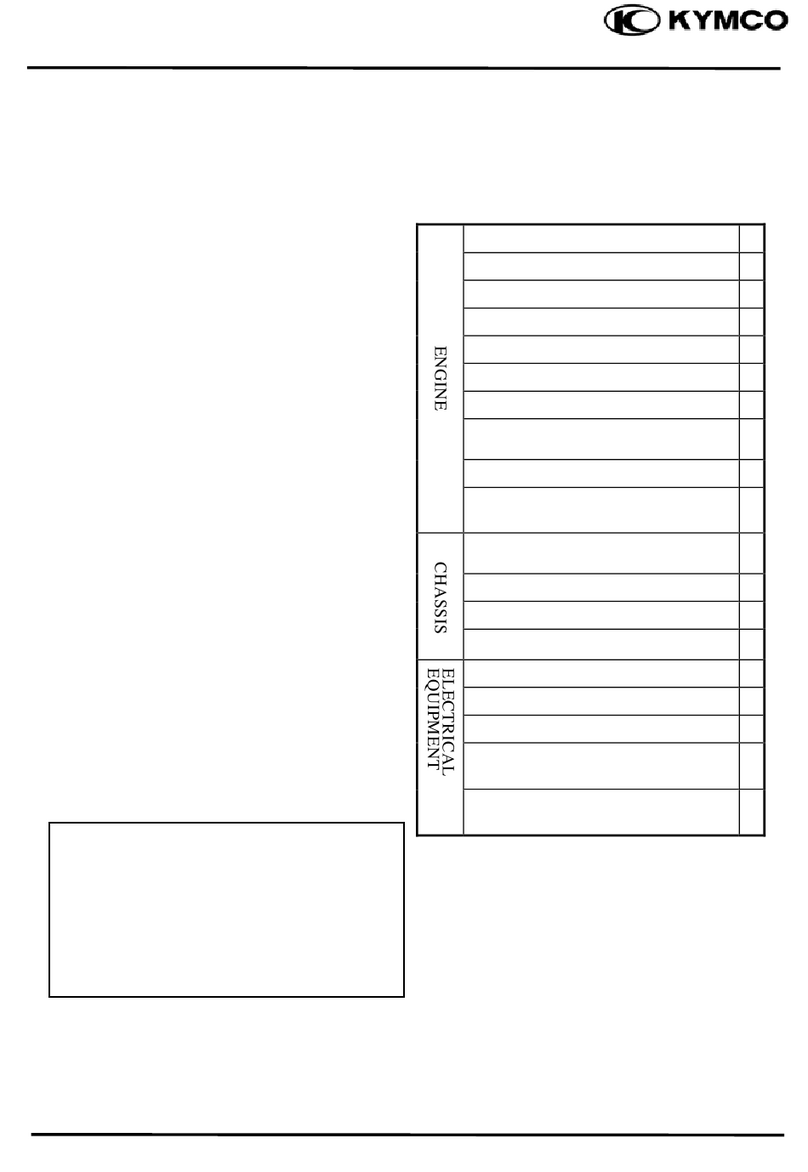

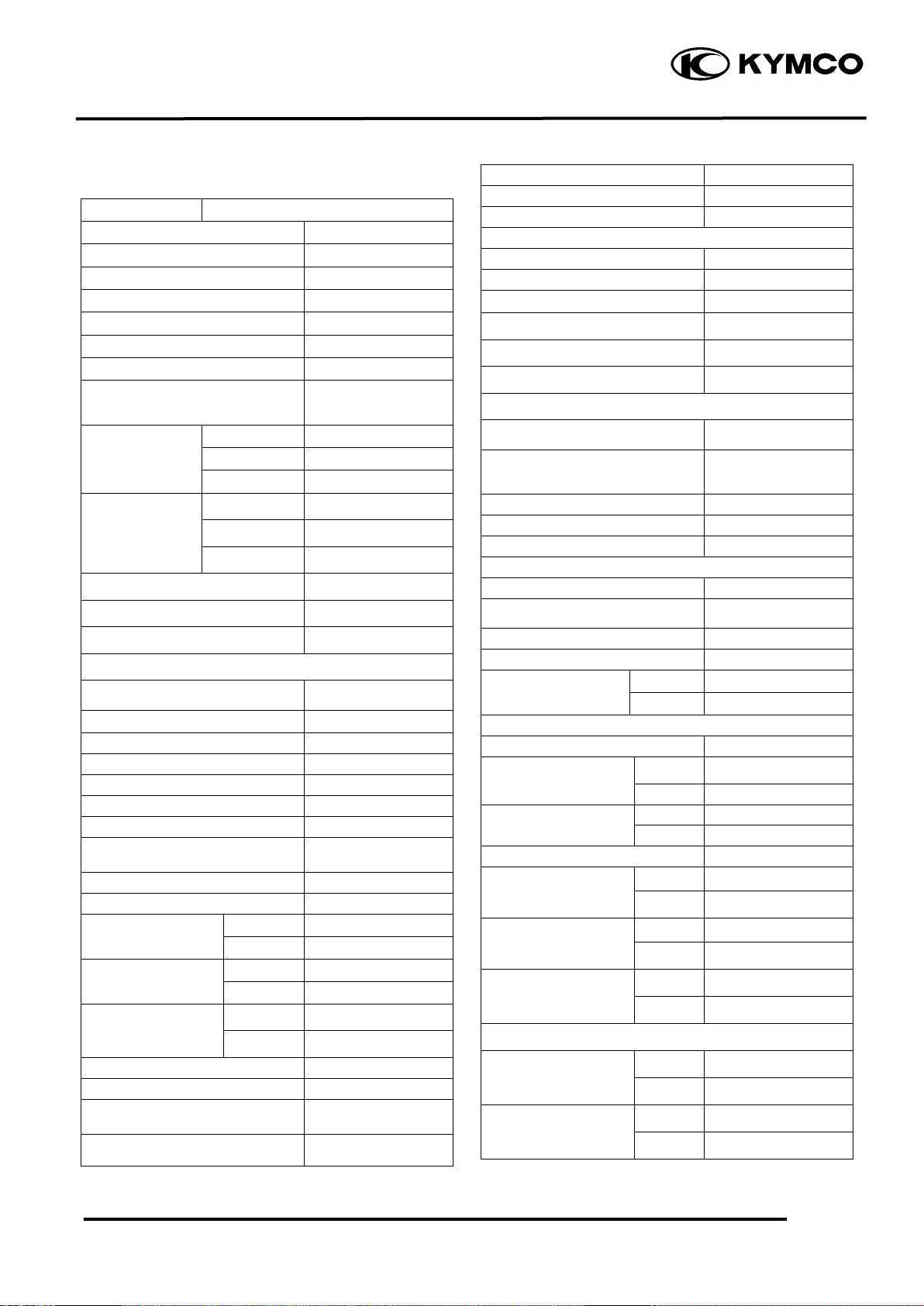

TABLE OF CONTENTS

GENERAL INFORMATION 1

EXHAUST MUFFLER/FRAME

COVERS 2

INSPECTION/ADJUSTMENT 3

LUBRICATION SYSTEM 4

ENGINE REMOVAL/INSTALLATION 5

CYLINDER HEAD/VALVES 6

CYLINDER/PISTON 7

DRIVE AND DRIVEN PULLEYS/V-

BELT 8

FINAL REDUCTION 9

A.C. GENERATOR/STARTER

CLUTCH 10

CRANKCASE/CRANKSHAFT 11

COOLING SYSTEM 12

FUEL INJECTION SYSTEM 13

STEERING HANDLEBAR/FRONT

WHEEL/FRONT BRAKE/FRONT

SHOCK ABSORBER/FRONT FORK

14

REAR BRAKE/REAR FORK/REAR

WHEEL/REAR SHOCK ABSORBER` 15

BATTERY/CHARGING SYSTEM 16

IGNITION SYSTEM 17

STARTING SYSTEM 18

LIGHTS SWITCHES / FUEL PUMP 19

EVAPORATIVE EMISSION CONTROL

SYSTEM 20

ABS ANTI-LOCK BRAKE SYSTEM 21

The information and contents

included in this manual may be

different from the motorcycle in case

specifications are changed.

CHASSIS ELE

TRI

AL

EQUIPMENT

ENGINE