Instruction manual | Status - November 2023 Page 2

1. PREFACE .............................................................................................................................................3

2. NOTES ON USING THE INSTRUCTION MANUAL .................................................................................3

ABOUT THIS INSTRUCTION MANUAL .......................................................................................................................... 3

SYMBOLS AND MARKINGS.......................................................................................................................................... 3

3. INTENDED USE .....................................................................................................................................4

4. GENERAL SAFETY INSTRUCTIONS .......................................................................................................5

PRODUCT SAFETY ...................................................................................................................................................... 5

GENERAL SAFETY INSTRUCTIONS............................................................................................................................... 5

ASSEMBLY AND INSTALLATION ................................................................................................................................. 6

OPERATION................................................................................................................................................................ 6

MAINTENANCE .......................................................................................................................................................... 6

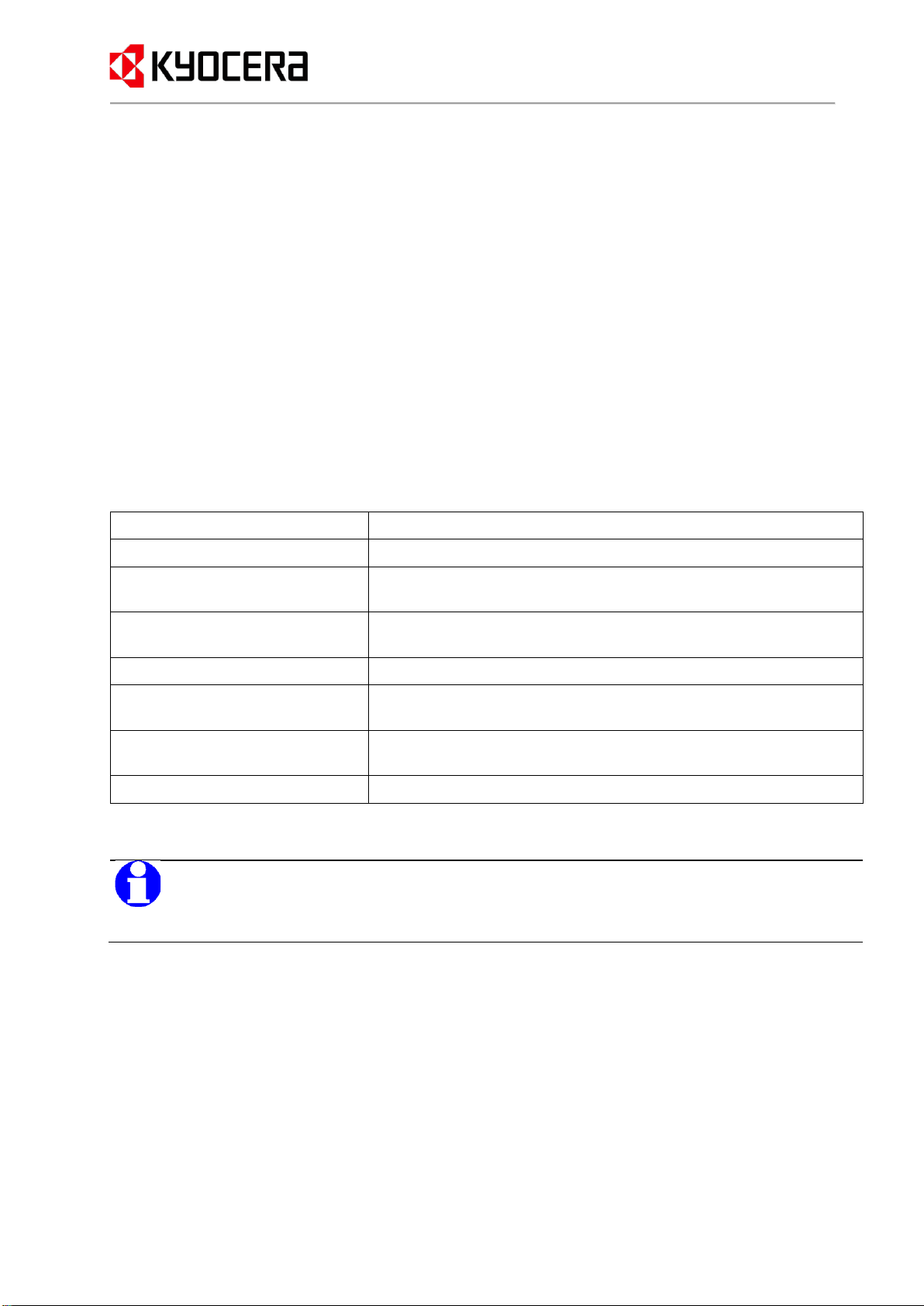

5. SYSTEM PROPERTIES............................................................................................................................7

MATERIAL ................................................................................................................................................................. 7

CONTROL SYSTEM...................................................................................................................................................... 7

TECHNICAL DATA ...................................................................................................................................................... 7

ACCESSORIES............................................................................................................................................................. 7

SCOPE OF SUPPLY....................................................................................................................................................... 8

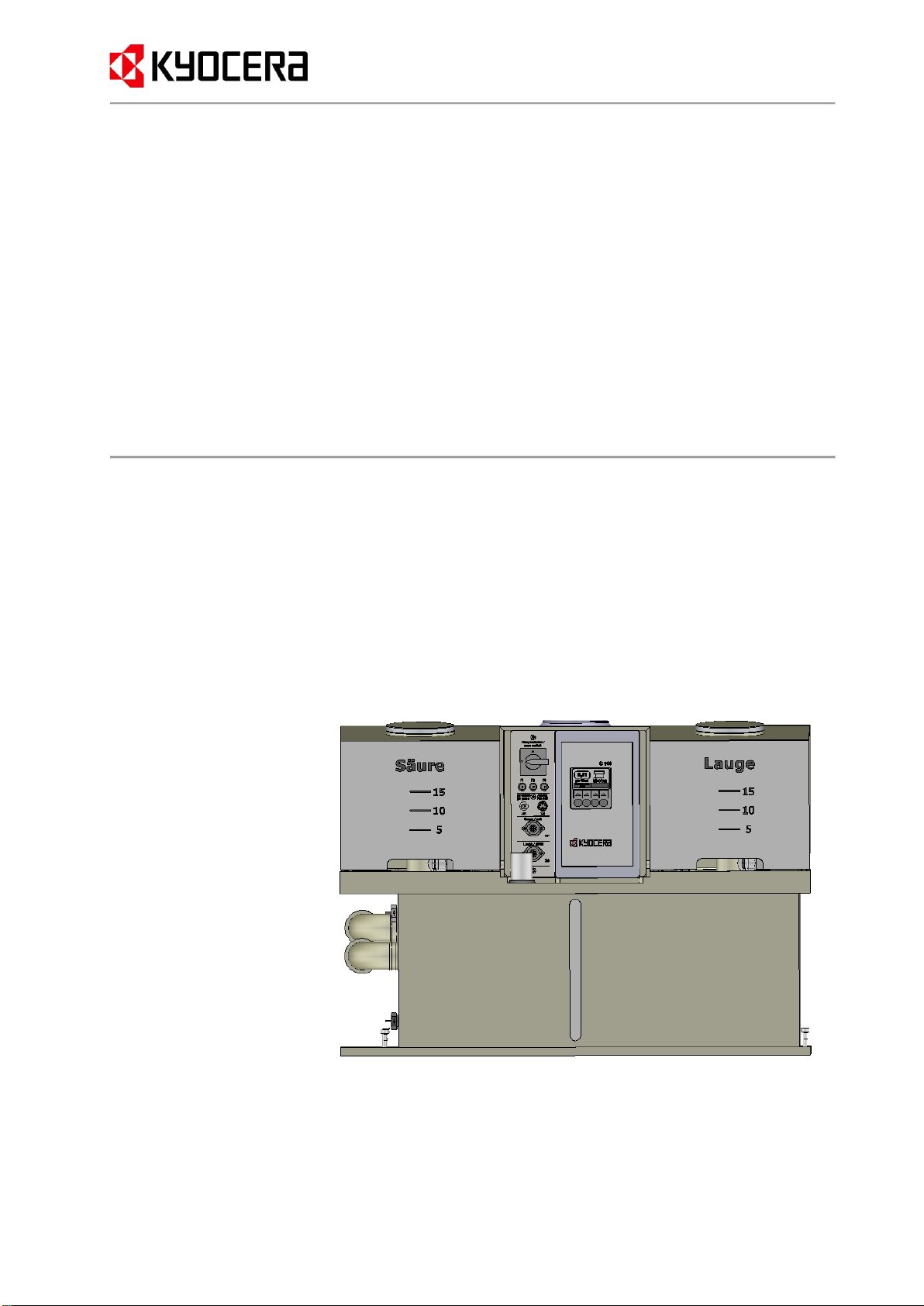

6. PRODUCT DESCRIPTION .....................................................................................................................8

FUNCTION.................................................................................................................................................................. 8

COMPONENTS ............................................................................................................................................................ 8

CONTROL ELEMENTS.................................................................................................................................................. 9

LCD DISPLAY WITH KEYPAD IN AUTOMATIC MODE ................................................................................................... 9

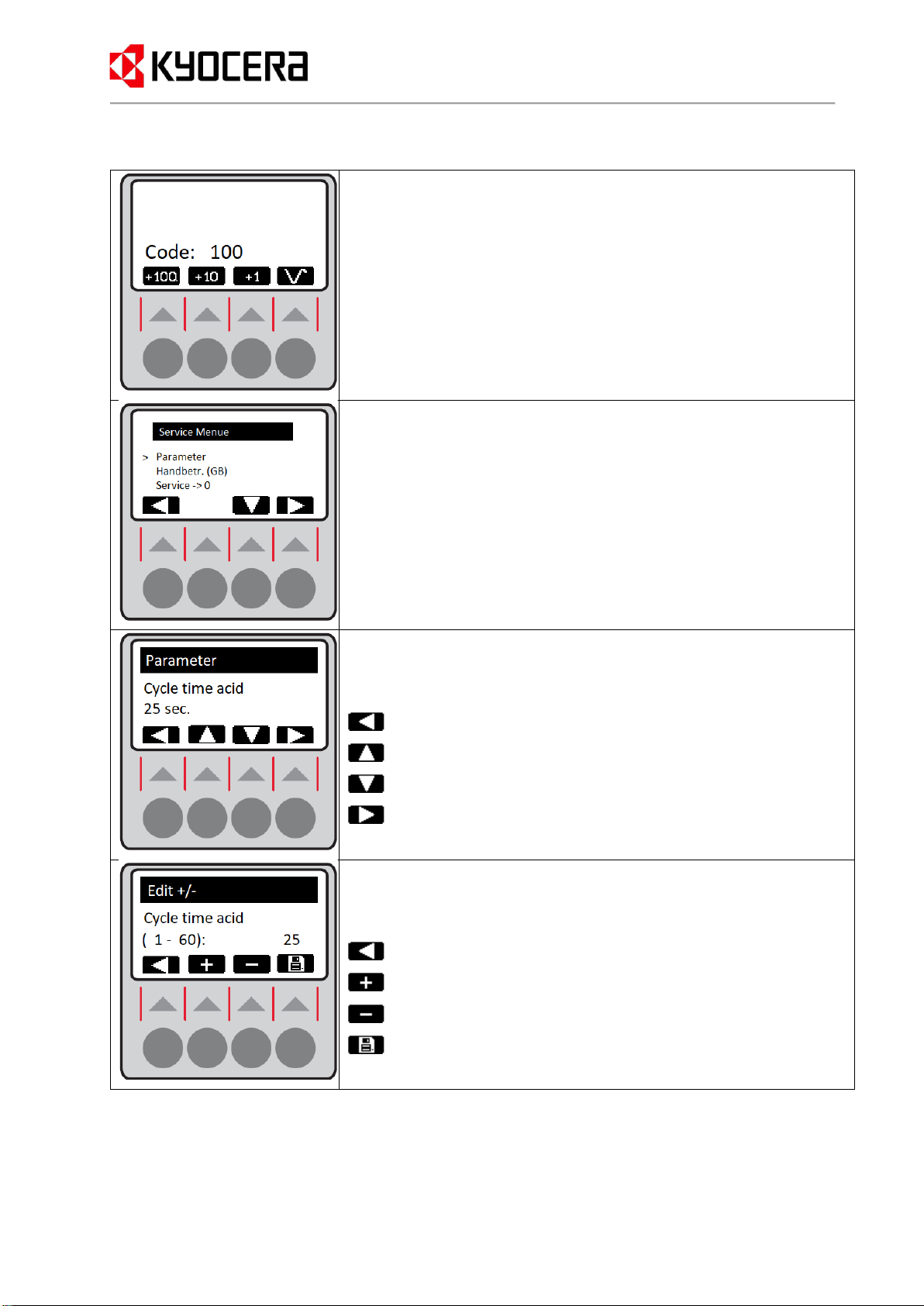

LCD DISPLAY WITH KEYPAD IN SERVICE MODE ....................................................................................................... 10

DEFINITION OF THE NEUTRAL RANGE....................................................................................................................... 11

NEUTRALISATION PROCESS (BATCH OPERATION):.................................................................................................... 11

7. OPERATION.......................................................................................................................................12

COMMISSIONING...................................................................................................................................................... 12

OPERATING INSTRUCTIONS ...................................................................................................................................... 12

CALIBRATION OF THE PHELECTRODE...................................................................................................................... 12

TOPPING UP THE CHEMICALS.................................................................................................................................... 14

8. MALFUNCTIONS AND TROUBLESHOOTING .....................................................................................15

9. SHUT DOWN THE DEVICE ..................................................................................................................16

10. ASSEMBLY .........................................................................................................................................17

QUALITY CONTROL.................................................................................................................................................. 17

UNPACKING ............................................................................................................................................................. 17

CHECKS ON DELIVERY ............................................................................................................................................. 17

ENVIRONMENTAL PROTECTION AND PACKAGING..................................................................................................... 17

11. INSTALLATION ...................................................................................................................................17

PLUMBING CONNECTIONS ........................................................................................................................................ 18