3/11/2009 3

Table of Contents

Introductions – General Information ................ 4

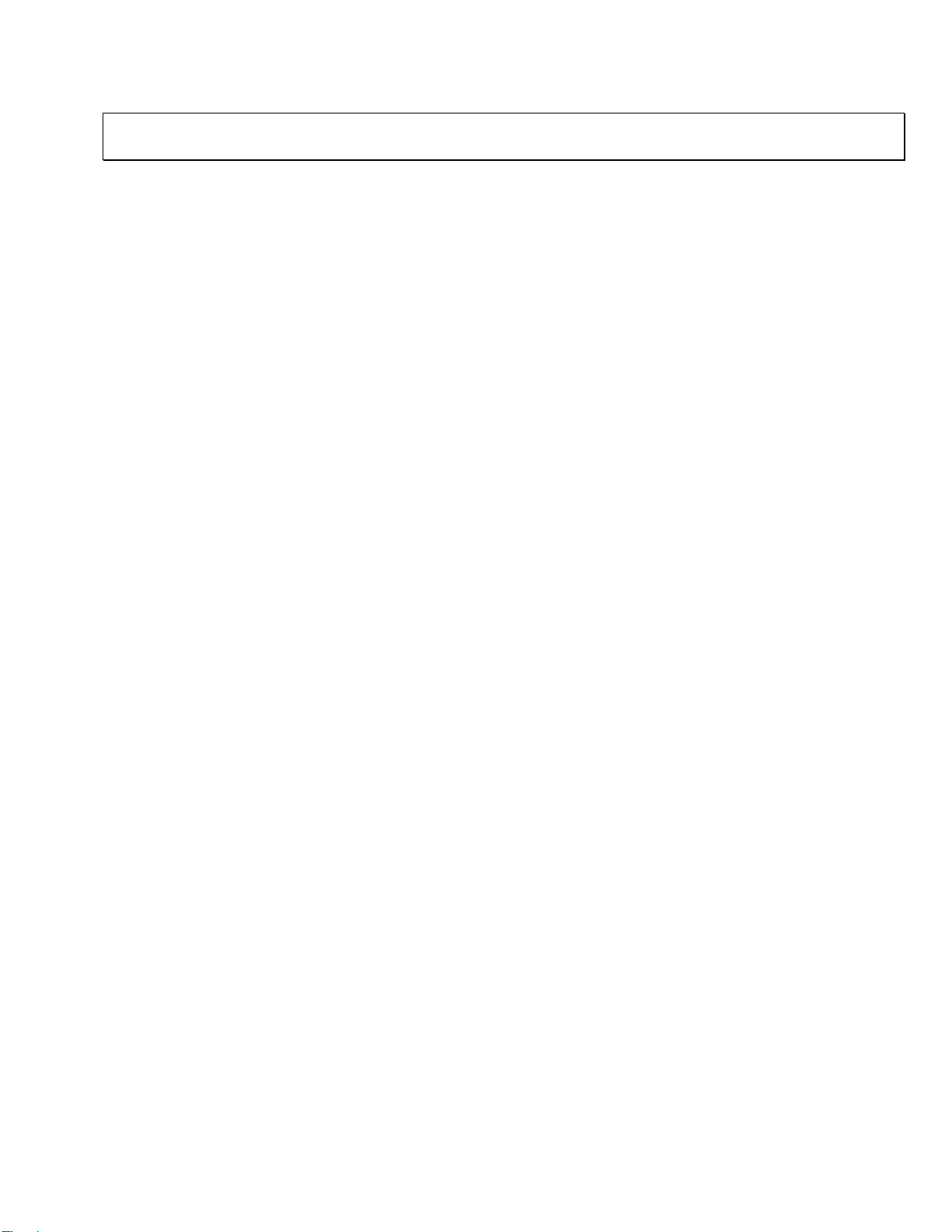

Case Description............................................... 4

Standard Reach-in Case................................ 4

Receiving/Shipping Damage/Lost Items .......... 5

Refrigerant ........................................................ 5

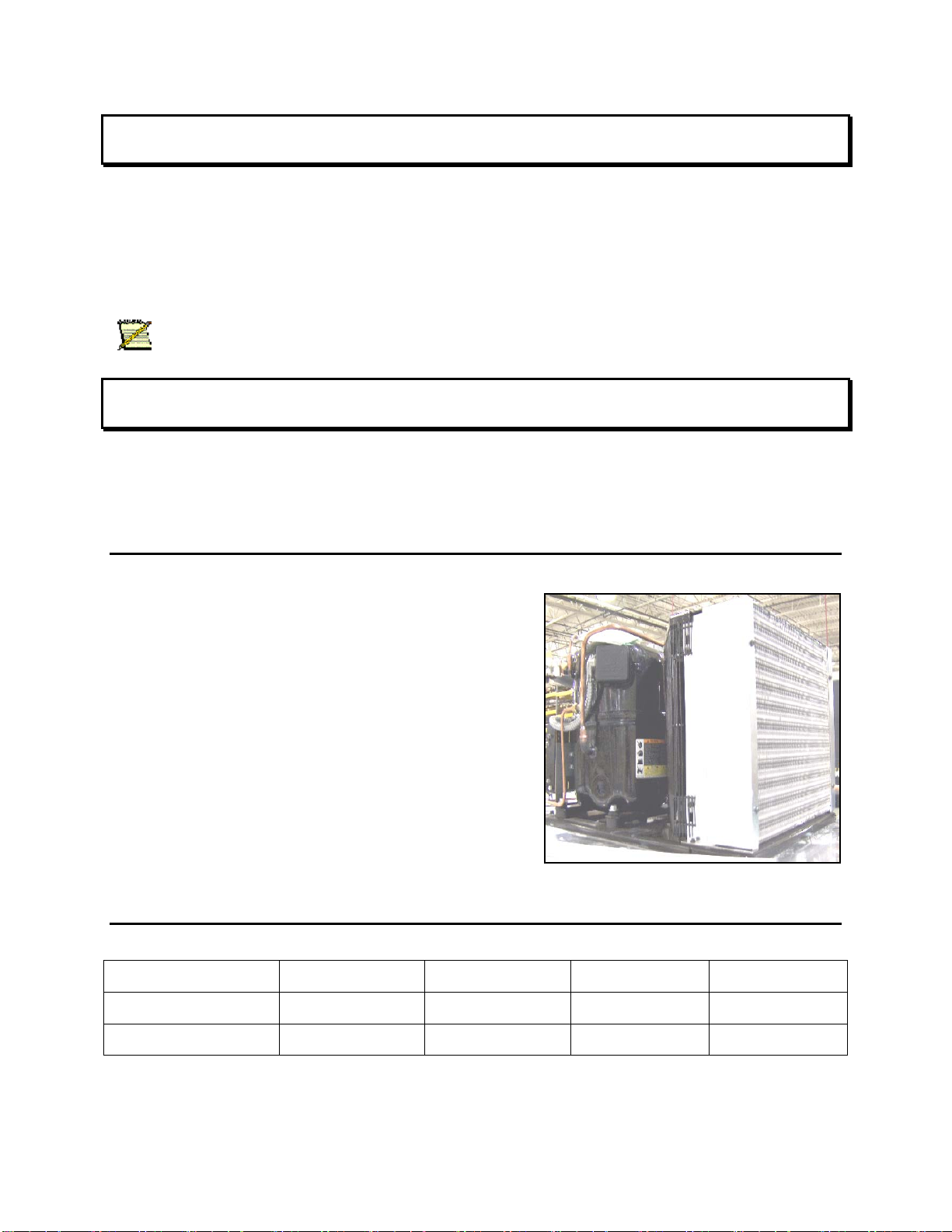

Modular Condensing Unit: ........................... 5

Refrigerant Charge........................................ 5

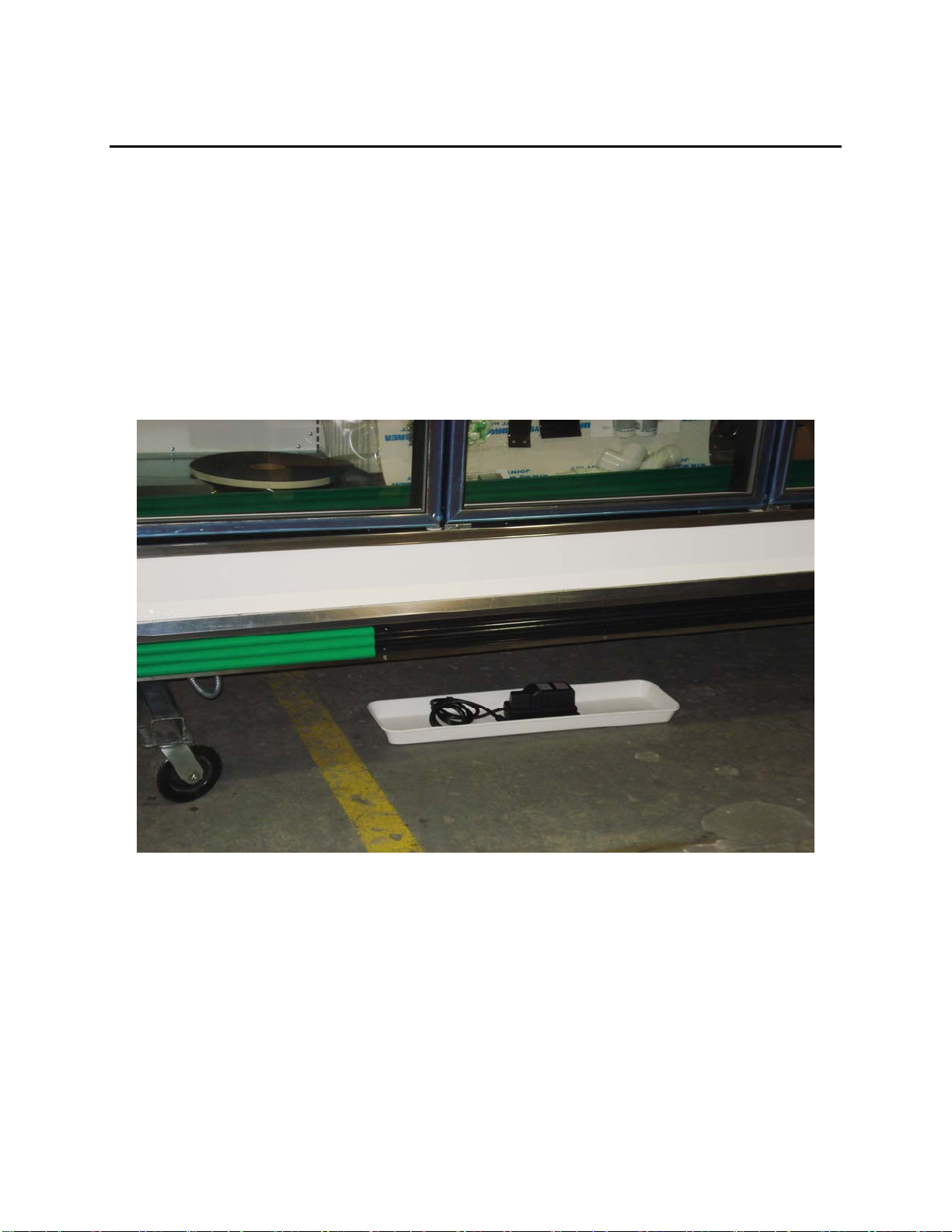

Condensate Pump.......................................... 6

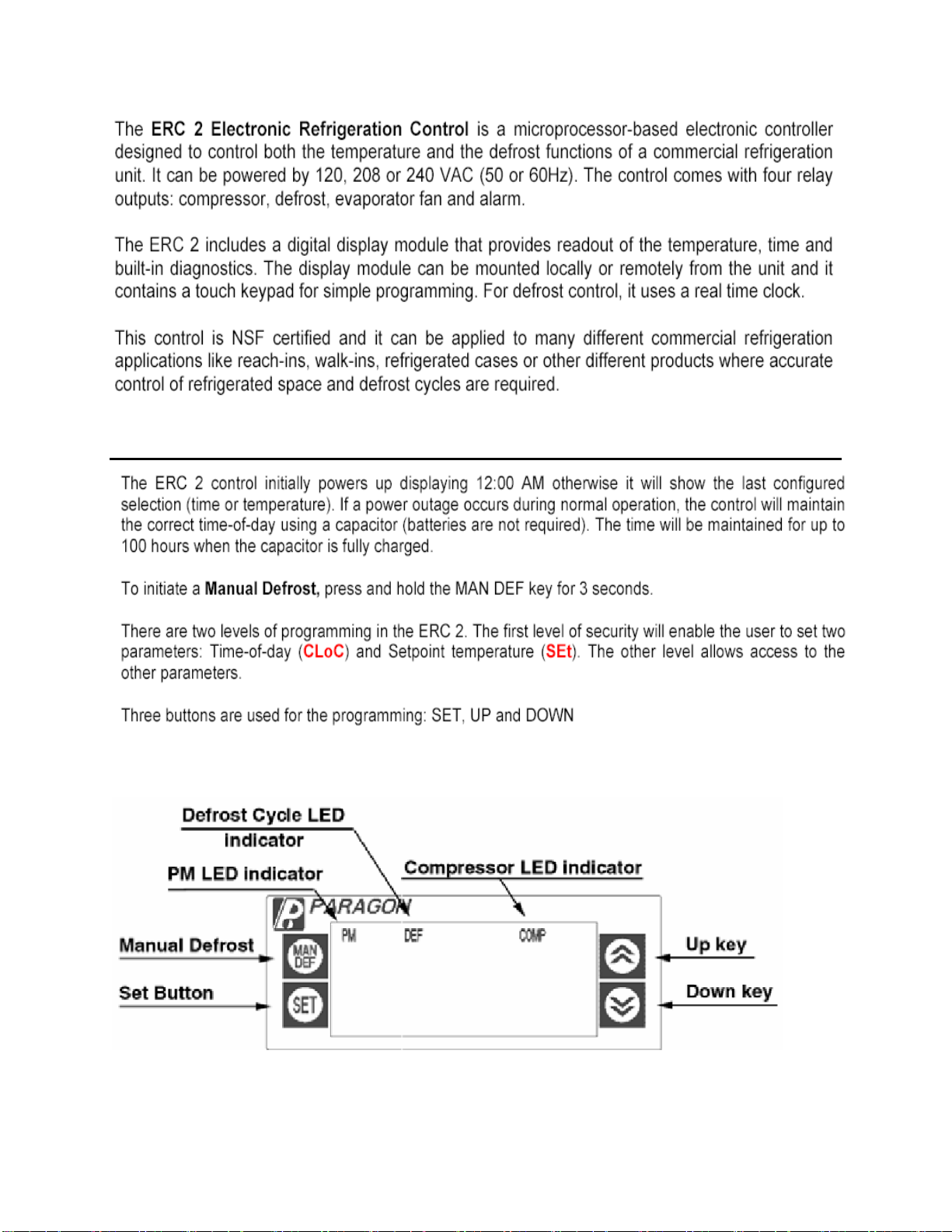

Case Controller ............................................. 7

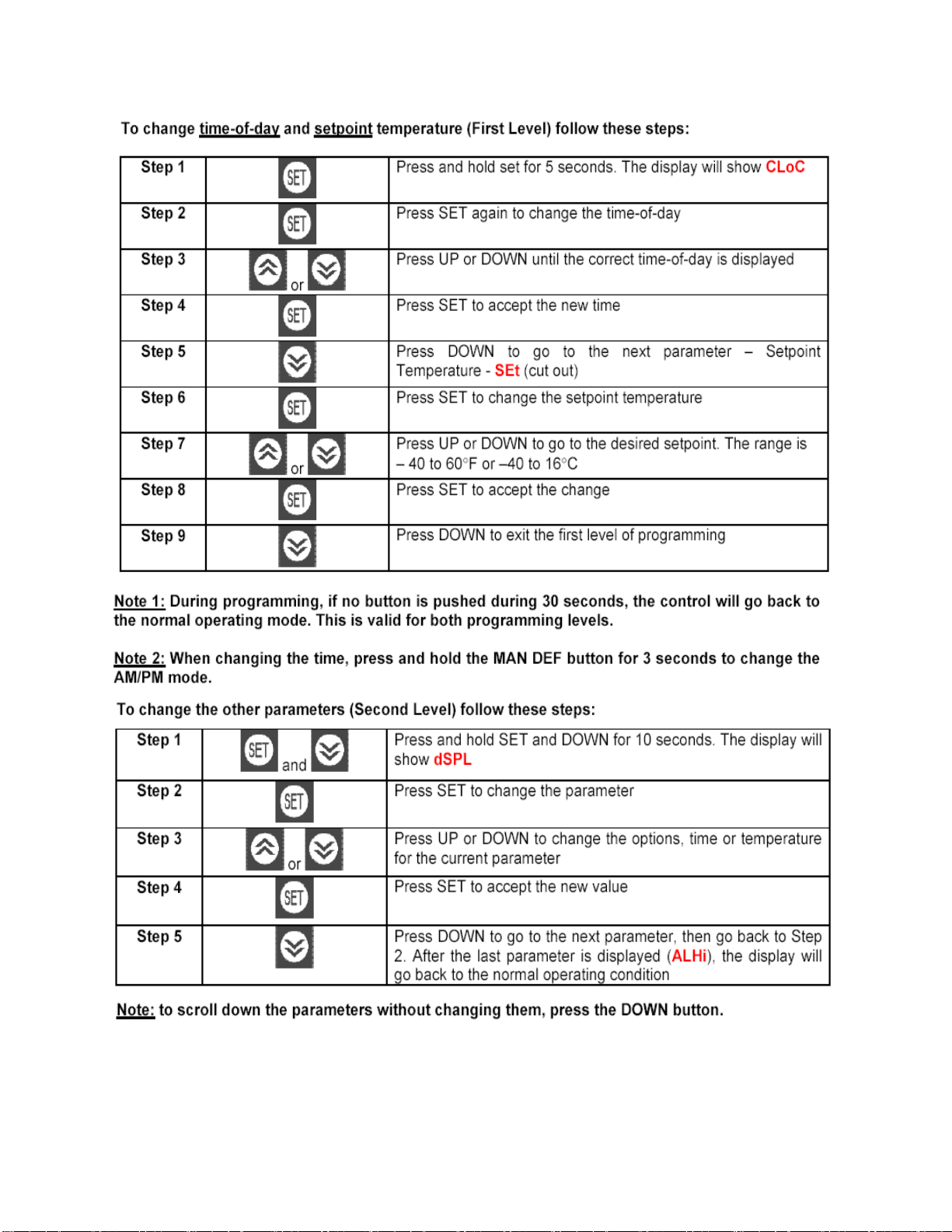

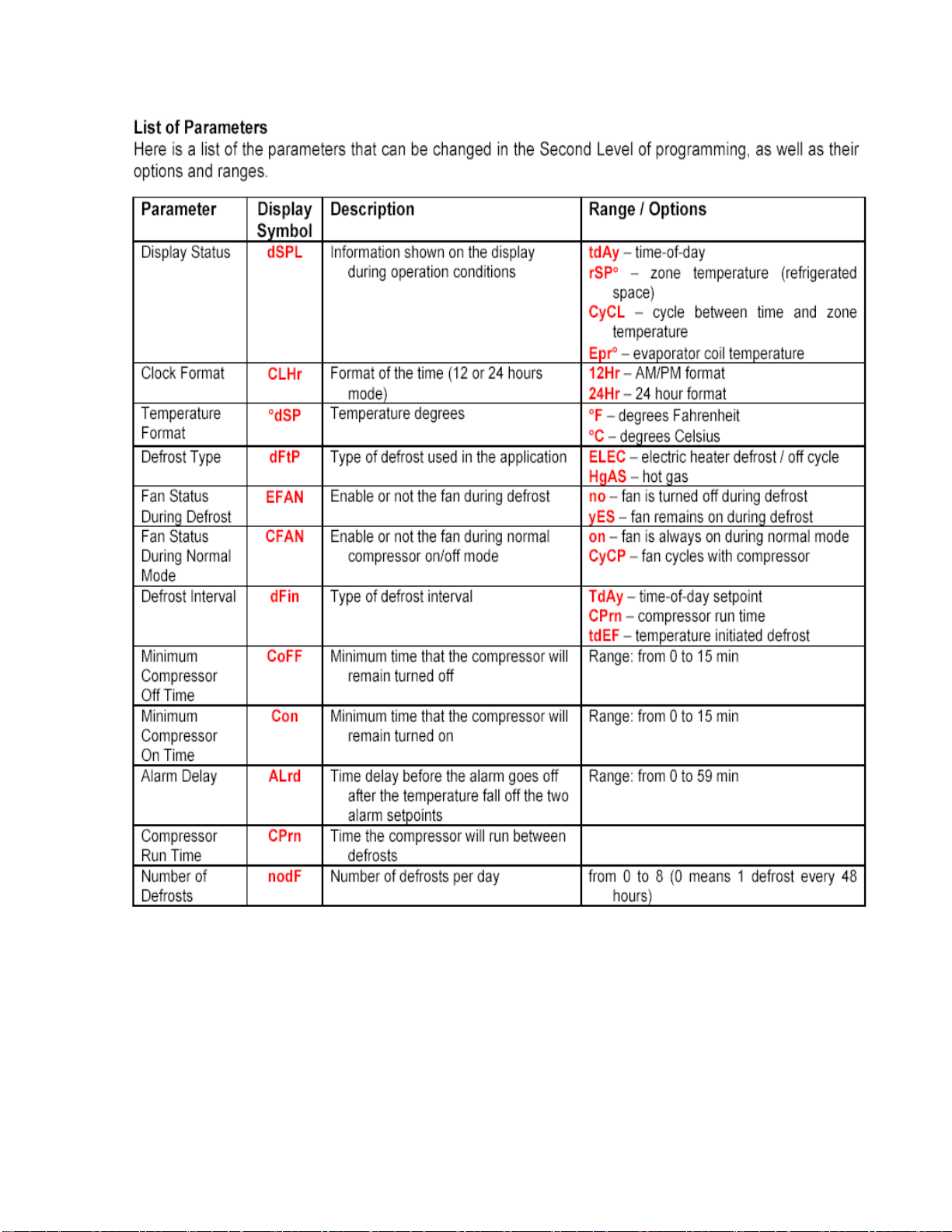

Programming Paragon Case Controller........ 8

Condensate Evaporator Pan Heater ............ 13

Buck & Boost Transformer (optional)........ 13

Plan View and Cross Section.......................... 15

Case Data........................................................ 16

Case Installation.............................................. 18

Preparation (with modular condensing unit)18

Installation....................................................... 18

Unpacking................................................... 18

Installing Assembly .................................... 19

Modular Condensing Unit............................... 20

Mounting Base & Enclosure....................... 20

Refrigeration Connections.......................... 22

Coupling Connection Instructions .......... 22

Initial Connections.................................. 23

Coupling Description.............................. 25

Waste Outlet (Drip Pipe) Description and

Location .................................................. 29

Drain Strainer.......................................... 29

Electrical Connections – General.................... 30

Electrical Termination ................................ 30

Wiring Diagrams......................................... 30

Fan Relay Assembly/Wiring....................... 34

Expansion Valve and Superheat ..................... 35

Operation......................................................... 36

Loading....................................................... 36

Normal Operation (with modular

condensing unit).......................................... 36

Cleaning...................................................... 37

Parts Drawing.............................................. 40

Parts List –

QDV5V(14)(34)/QIV5V(14)(34)............... 41

Warranty ......................................................... 42

Parts Warranty Policy................................. 42

New Equipment Parts Shortages and

Defects ........................................................ 42

Parts Ordering Procedure............................ 42

Return Authorization Procedure................. 42

One-Year Warranty..................................... 43