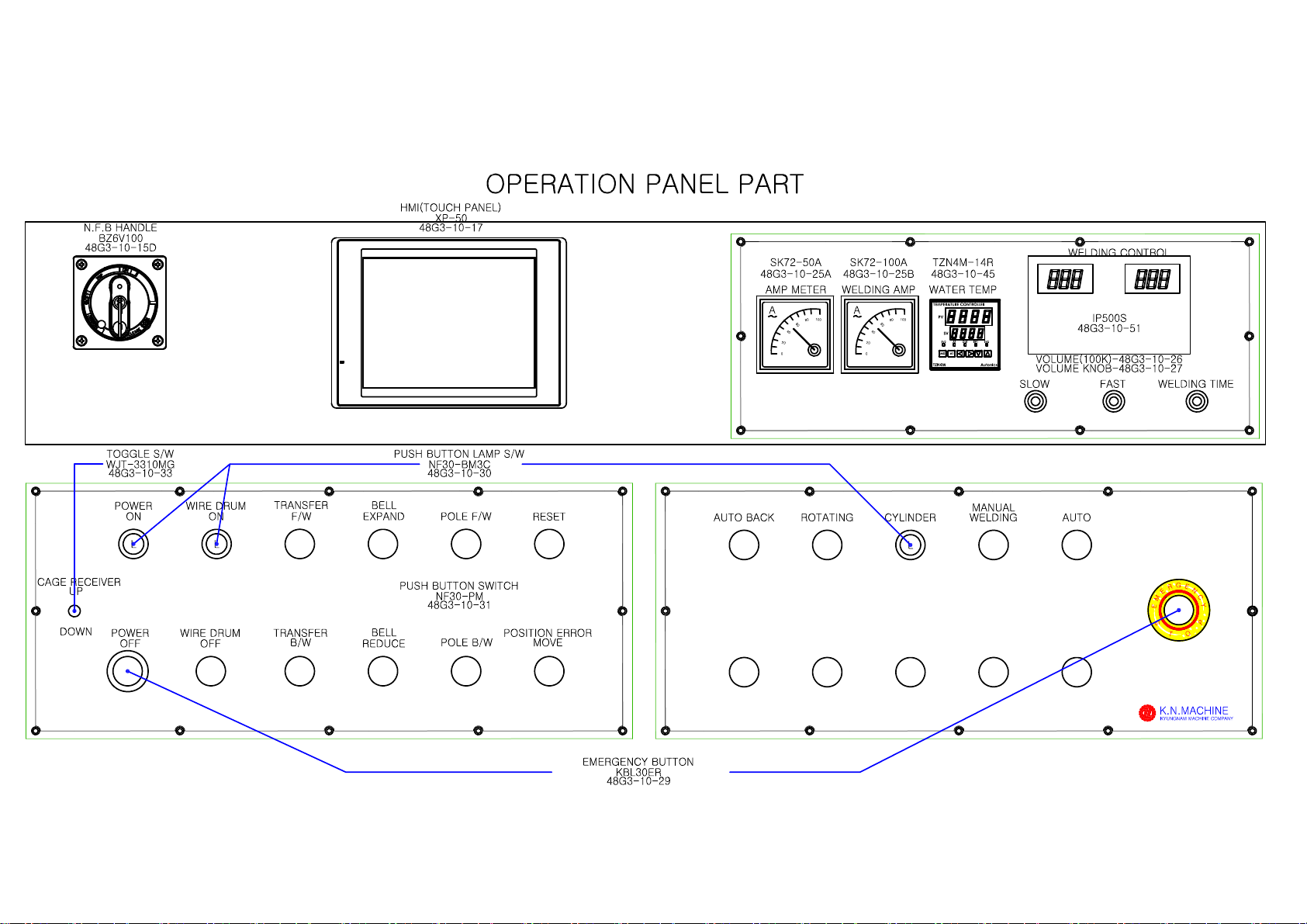

POSITION ERROR MOVE : In case of TRANSFER/BELL POSITION ERROR, push this button.

- TRANSFER or BELL is positioned out of Max./Min. position.

Push POSITION ERROR MOVE button together with TRANSFER

F/W, B/W, BELL EXPAND or BELL REDUCE to move it inside.

※ Note: In case BELL POSITION ERROR, BELL expands or reduces,

if push POSITION ERROR MOVE button with BELL EXPAND or

BELL REDUCE button. Please check the position visually before

pushing button.

AUTO BACK : After moving center drum, BELL expand or POLE forward, push this button

to reduce BELL and POLE backward completely at initial position automatically.

ROTATING : Rotate the drum clockwise manually as long as button pressed

- During the AUTO operation, it is not works.

CYLINDER OPEN/CLOSE: Pole CYLINDER closes to fix up a spiral wire for welding.

- During CYLINDER is closed, BELL REDUCE and POLE B/W is not works.

- Press CYLINDER button to open and press it again to close.

- After 10 seconds CYLINDER opened, BELL REDUCE and POLE B/W will moves.

- After CYLINDER closed, push AUTO button, but CYLINDER open and machine

is stop if TURN TABLE is "OFF". Reset and TURN TABLE should be "ON".

MANUAL WELDING : Manual weld 1 point until setting welding time to secures a spiral wire

to be welded on longitudinal wire firmly. Push it longer time, but weld

with set time.

AUTO: This button pressed, 1 cycle of operation will be done automatically and stop after

drum turning 1 revolution.

- Before pressing AUTO button, check all set up data are correct.

※ During AUTO running operation, do not push any other button.

※ After CYLINDER closed, push AUTO button, but CYLINDER open and machine

is stop if TURN TABLE is "OFF". Reset and TURN TABLE should be "ON".

※ Before start AUTO running, please check TURN TABLE is "ON"

EMERGENCY STOP: If EMERGENCY STOP switch is pressed during the automatic operation,

all functions except TURN TABLE are stopped, and EMERGENCY STOP ON

(on EMERGENCY STOP INFORMATION of TOUCH PANEL) is lit.

- Release EMERGENCY STOP button, and press RESET button.