II Note and symbols

NOTE:

® Names and Logo are registered trademarks of Narda Safety Test Solutions GmbH and L3Harris

Communications Holdings, Inc. – Trade names are trademarks of the owners.

If the instrument is used in any other way than as described in this User’s Manual,

it may become unsafe.

Before using this product, the related documentation must be read with great care and fully understood to

familiarize with all the safety prescriptions.

To ensure the correct use and the maximum safety level, the User shall know all the instructions and

recommendations contained in this document.

This product is a Safety Class I instrument according to IEC classification and has

been designed to meet the requirements of EN61010-1 (Safety Requirements for

Electrical Equipment for Measurement, Control and Laboratory Use).

In accordance with the IEC classification, the power supply of this product meets requirements Safety Class II and

Installation Category II (having double insulation and able to carry out mono-phase power supply operations).

It complies with the requirements of Pollution Class II (usually only non-conductive pollution). However,

occasionally it may become temporarily conductive due to condense on it.

The information contained in this document is subject to change without notice.

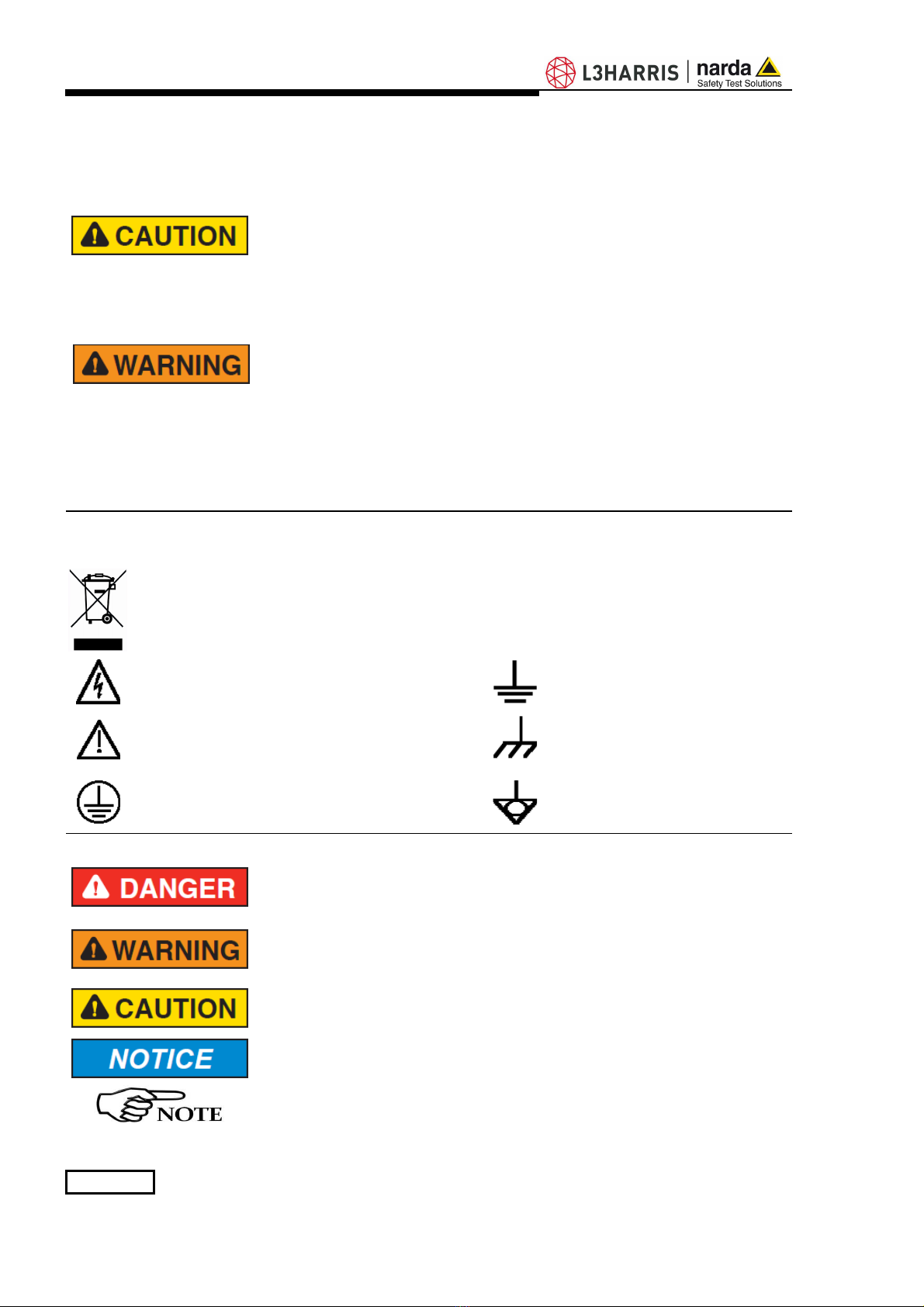

EXPLANATION OF ELECTRICAL AND SAFETY SYMBOLS :

You now own a high-quality instrument that will give you many years of reliable service.

Nevertheless, even this product will eventually become obsolete. When that time comes, please

remember that electronic equipment must be disposed of in accordance with local regulations.

This product conforms to the WEEE Directive of the European Union (2002/96/EC) and belongs to

Category 9 (Monitoring and Control Instruments). You can return the instrument to us free of

charge for proper environment friendly disposal. You can obtain further information from your

local Narda Sales Partner or by visiting our website at www.narda-sts.it .

Warning, danger of electric shock

Earth

Read carefully the Operating Manual and its

instructions, pay attention to the safety

symbols.

Unit Earth Connection

Earth Protection

Equipotential

EXPLANATION OF SYMBOLS USED IN THIS DOCUMENT :

The DANGER sign draws attention to a serious risk to a person’s safety,

which, if not avoided, will result in death or serious injury. All the

precautions must be fully understood and applied before proceeding.

The WARNING sign indicates a hazardous situation, which, if not avoided,

could result in death or serious injury. All the precautions must be fully

understood and applied before proceeding.

The CAUTION sign indicates a hazardous situation, which, if not avoided,

could result in minor or moderate injury.

The NOTICE sign draws attention to a potential risk of damage to the

apparatus or loss of data.

The NOTE sign draws attention to important information.