Model 89000B Assembly and Users’ Instructions

9

This schedule allows the animal to explore four arms. It keeps track of the arms explored and

then re-explored. Once each of the four arms are explored the schedule ends.

The default arms are #1, #3, #5, and #7 - essentially a plus configuration. To determine

exploration, “states” are used to keep track of where the animal has been. Each arm has an

associated “state”, using the “ArmFlag” counter, and are defined as:

State “0” - Runway not explored

State “1” - Reached end of runway (Cup Sensor)

State “2” - Exiting runway (Entry Sensor)

State “3” - Another runway is entered (Entry Sensor on other runways)

To map where the animal has been the counter for each arm is incremented as these “states” are

reached. State “3” is unique in that the animal must enter another arm to know it has fully exited

the arm explored. The “ArmFlag” is further incremented from 3 onward to indicate the associated

runway is re-explored. So, if the “ArmFlag” for runway 1 is incremented to 6 then the runway was

re-explored at least two times. Once the “ArmFlag” reaches “3” each Entry Sensor or Cup Sensor

detection causes the “ArmFlag” to increment. The resulting data file can be analyzed to

determine the amount of re-exploration of an arm, essentially the number of times the Entry

Sensor and the Cup Sensor were activated.

Notes:

1. Automatic Door – Turn ON = Door opened or Bridge raised

2. Automatic Door – Turn OFF = Door closed or Bridge lowered

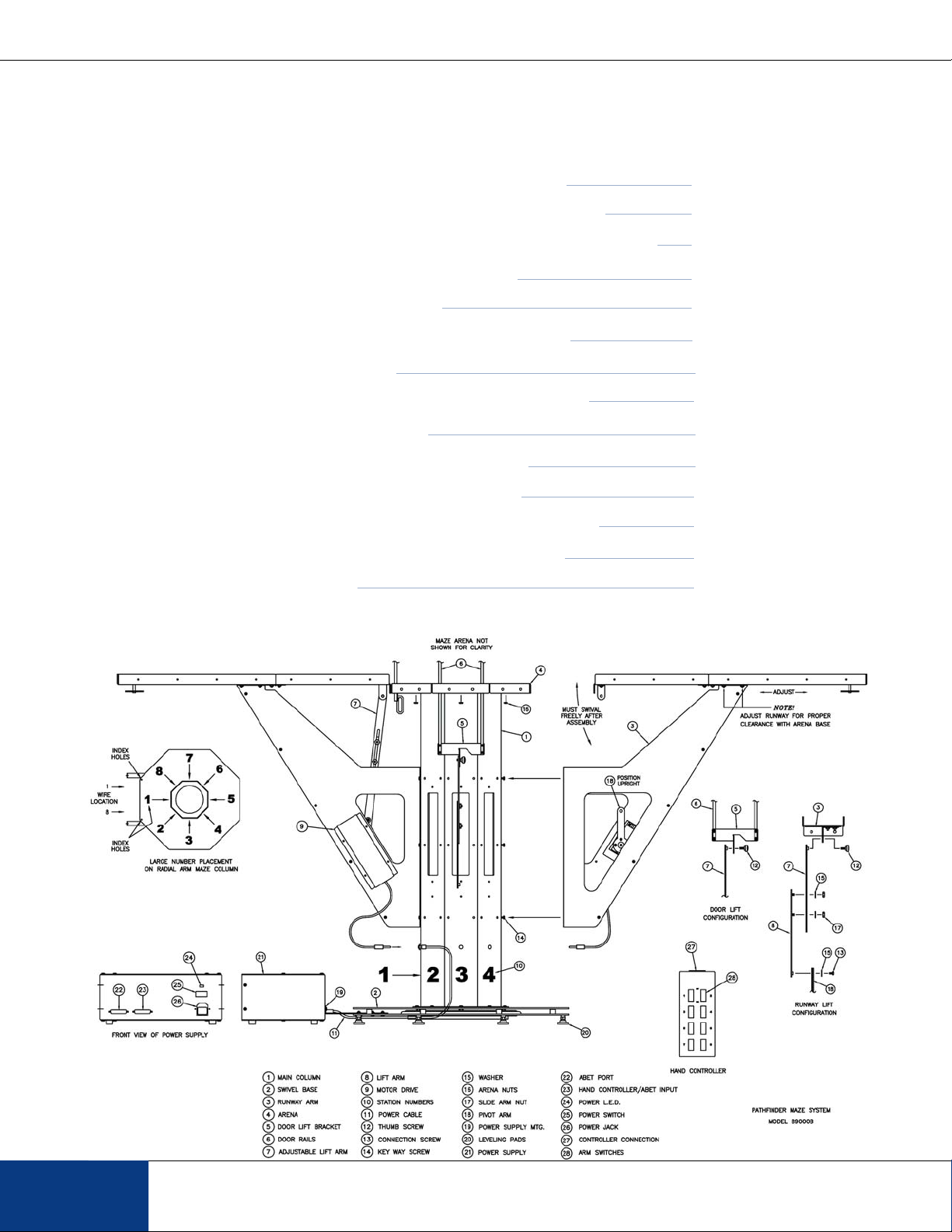

3. Entry Sensors for arms 1 to 8 are physically wired to inputs 1, 3, 5, 7, 9, 11, 13, 15

respectively.

4. Cup Sensors for arms 1 to 8 are physically wired to inputs 2, 4, 6, 8, 10, 12, 14, 16

respectively.

5. All photocell sensors are wired with the Red wire to 28VDC, Black wire to Common, the Blue

wire to the respective input.

(I) Example ABET Schedule