Thank you for investing in a 16-32 SuperMax by Laguna Tools drum sander. This drum sander is

one of a family of unique machines proudly offered by Laguna Tools. Every Laguna machine is

engineered for years of dependable service. Please feel free to contact Laguna Tools if you have a

question or suggestion. We appreciate working with you and your choice of a Laguna Tools machine

for your shop.

Regards,

Torben Helshoj

President & Founder Laguna Tools

Dealer Machinery Warranty

New woodworking machines sold by Laguna Tools carry a two-year warranty effective from the date of

dealer invoice to consumer. Machines sold through dealers must be registered with Laguna Tools within

30 days of purchase to be covered by this warranty. Laguna Tools guarantees all new machine sold to be

free of manufacturers’ defective workmanship, parts and materials. We will repair or replace, without

charge, any parts determined by Laguna Tools, Inc. to be a manufacturer’s defect. We require that the

defective item/part be returned to Laguna Tools with the complaint. An RMA (return merchandise

authorization) must be requested, from Laguna Tools, and included with any and all parts or machines

returned to Laguna Tools for warranty consideration. Any machines returned to Laguna Tools must be

returned with packaging in the same manner in which it was received. If a part or blade is being returned

it must have adequate packaging to ensure no damage is received during shipping. In the event the

item/part is determined to be damaged due to lack of maintenance, cleaning or misuse/abuse, the

customer will be responsible for the cost to replace the item/part, plus all related shipping charges. This

limited warranty does not apply to natural disasters, acts of terrorism, normal wear and tear, product

failure due to lack of maintenance or cleaning, damage caused by accident, neglect, lack of or

inadequate dust collection, misuse/abuse or damage caused where repair or alterations have been made

or attempted by others.

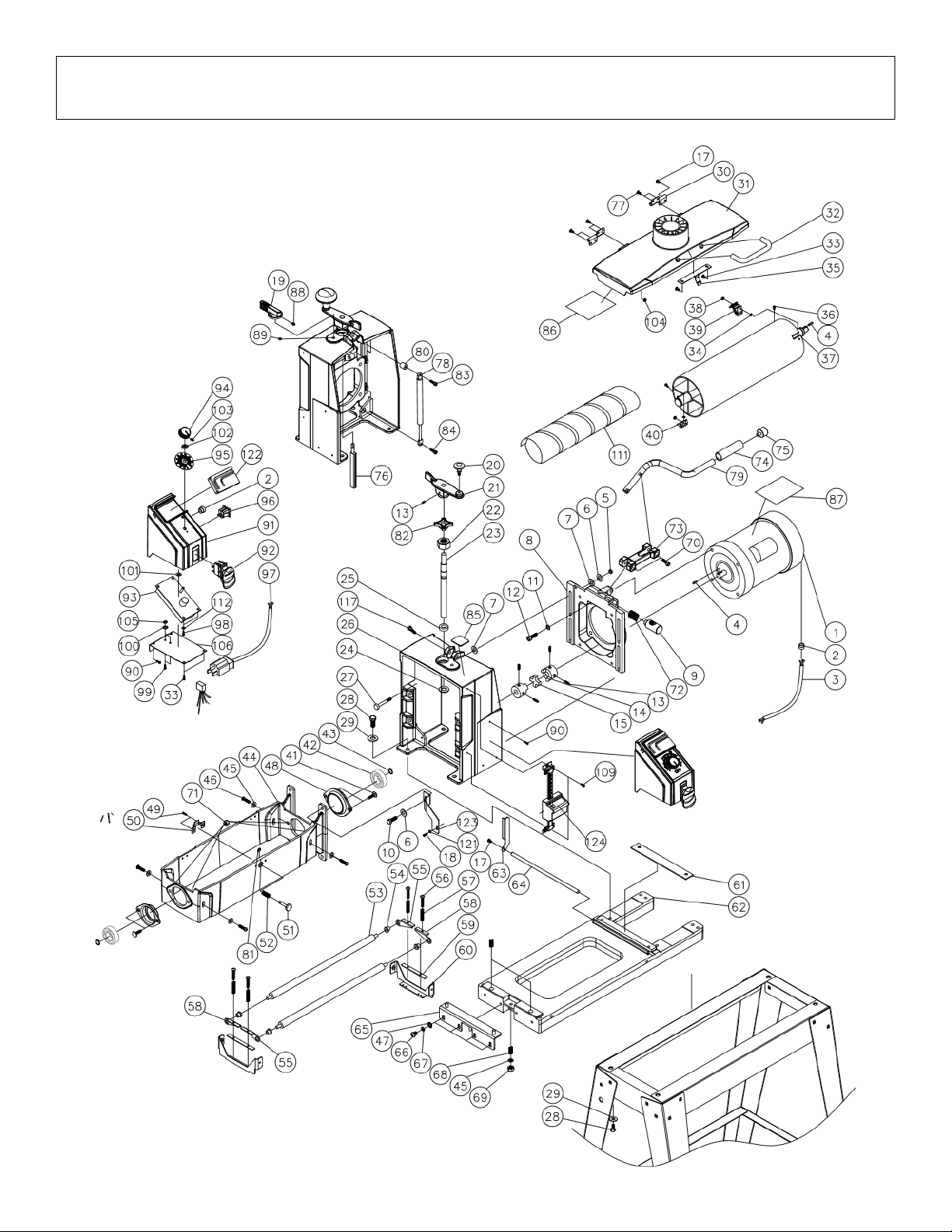

This manual applies to the 16-32 SuperMax by Laguna Tools drum sander. Enter the model number

and serial number below for quick reference when ordering accessories, supplies or parts.

Model: ___________

Serial: ___________

Laguna Tools 7291 Heil Avenue Huntington Beach CA 92606

800-234-1976 www.lagunatools.com