4

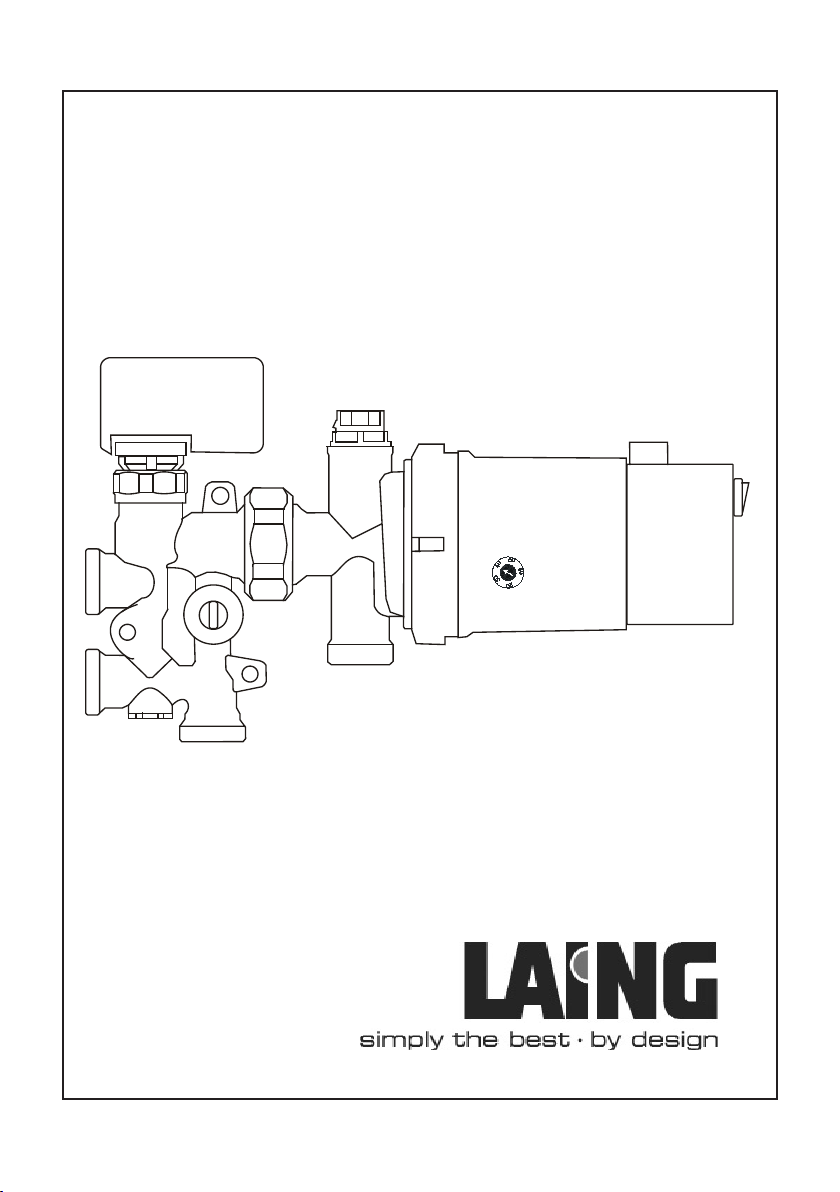

Installation and operation manual BM mini

www.laing.de

www.laing.de

Application

• TheBMminiisdesignedtosupplyoorheatingareasuptoapprox.40

sqm (from pipe 16x2 mm onwards) in one- or two-pipe-systems. The

connectionofupto2oorheatingcircuitsispossible.

• Three versions are available:

BM mini KF: Mixing set with room temperature guided control,

made of thermostat (10-26°C + frost protection)

with remote sensor (5 m).

BM mini RT: Mixing set for temperature guided control, made

of thermoelectric drive for the connection of a room

thermostat (room thermostat not included in

delivery- see accessories in product range).

BM mini KR: Mixing set with integrated constant temperature

control (20-70°C) for the connection of a room

thermostat (room thermostat not included in

delivery- see accessories in product range).

• The BM mini is provided with a temperature protection system that

restrictsthesupplytemperatureintheoorheatingcircuittomax.55°C.

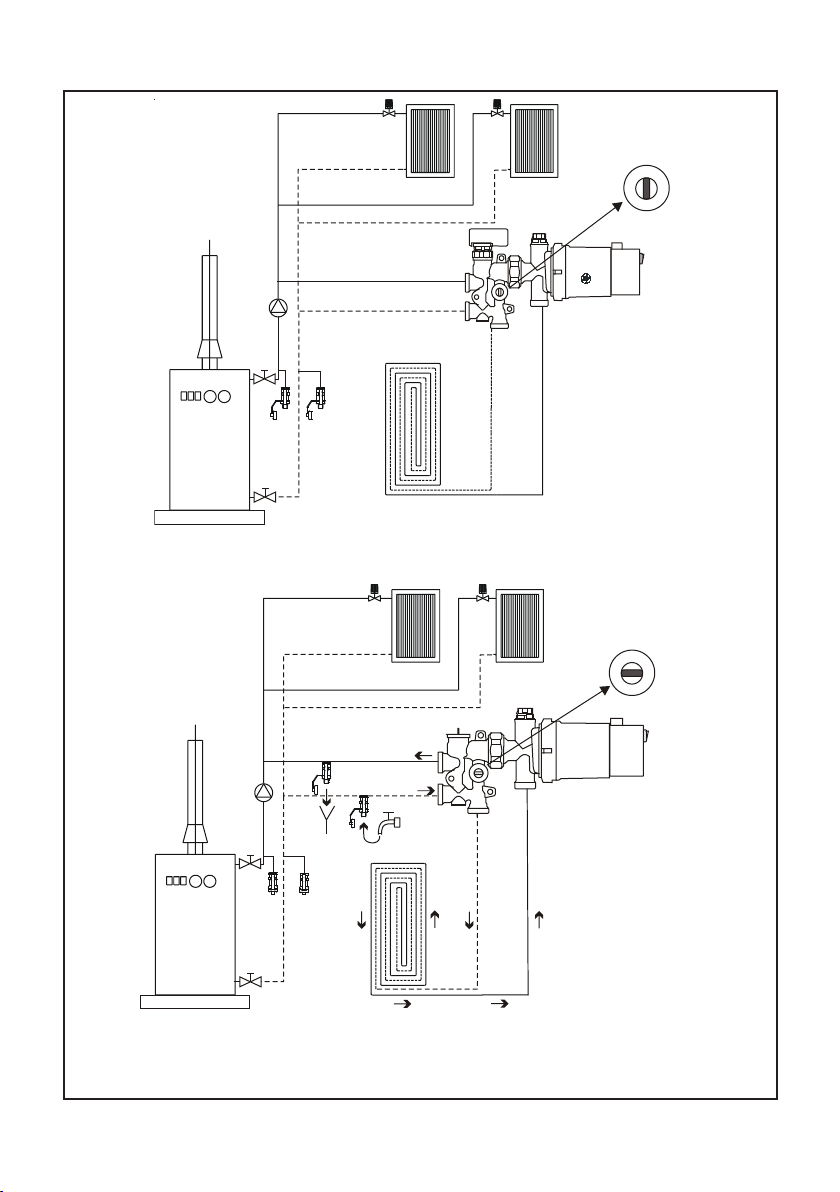

Mounting instructions

• BM mini will be connected directly to the existing radiator-/boiler circuit.

• When two circuits are connected to the BM mini, the shortest circuit

must be balanced by using an adjustable return screw connection.

• The BM mini has to be mounted in a horizontal position (see page 2).

Left or right connection to the radiator-/boiler circuit is possible (see

page 9).

• TheBMminihastobeinstalledonahigherlevelthantheoorheating

installation.