iii

Table of Contents

Important Safety Instructions ......................................................................................................................i

Electrical Safety......................................................................................................................................i

Mechanical Safety...................................................................................................................................i

Battery Safety ........................................................................................................................................i

Unit Location......................................................................................................................................... ii

Check for Damages................................................................................................................................ ii

Returns for Service ................................................................................................................................ ii

Inspection Checklist ............................................................................................................................... ii

Handling ............................................................................................................................................... ii

Table of Contents ..................................................................................................................................... iii

Table of Figures ....................................................................................................................................... iv

Model Scope/General Description ................................................................................................................1

Understanding the Model Number ...............................................................................................................1

Optional Accessories Included in the Inverter...............................................................................................1

1.0 Equipment Handling........................................................................................................................2

1.1 Storing the LTI2 PRO...................................................................................................................2

1.2 Moving the LTI2 PRO...................................................................................................................2

2.0 Installation.....................................................................................................................................2

2.1 Mounting the LTI2 PRO................................................................................................................2

2.1.1 Rack-Mounting the LTI2 PRO ................................................................................................3

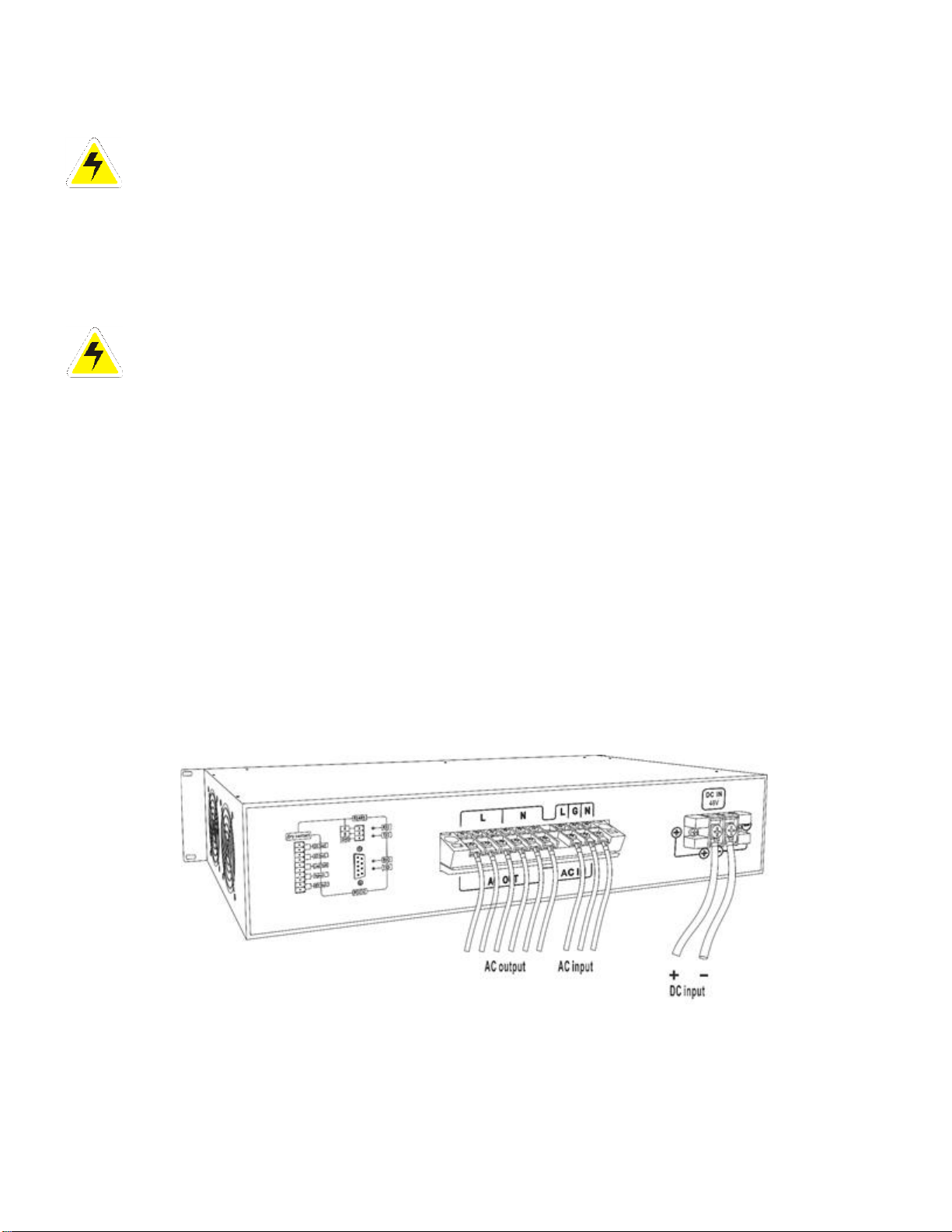

2.2 Electrical Connections ..................................................................................................................3

2.2.1 Input Wiring ........................................................................................................................4

2.2.2 Output Wiring......................................................................................................................4

2.2.3 Alarm Connections ...............................................................................................................5

3.0 Operation.......................................................................................................................................5

3.1 Operation Mode ..........................................................................................................................5

3.1.1 AC Power Supply Mode.........................................................................................................5

3.1.2 DC Power Supply Mode............................................................................................................5

3.2 Start-Up Sequence ......................................................................................................................6

3.2.1 Commissioning.....................................................................................................................6

3.2.2 Startup................................................................................................................................6

3.2.3 Shutdown .................................................................................................................................6

3.2.4 Mute ........................................................................................................................................6

3.3 Understanding the Alarms.................................................................................................................6

3.3.1 LED lights, LCD screen, and Buttons............................................................................................6

3.3.2 LED and Alarm Indications Details.............................................................................................7

3.3.3 LCD Menu...............................................................................................................................8

4.0 Troubleshooting...................................................................................................................................9

Appendix A: Technical Specifications ......................................................................................................... 10

Technical Specifications (Cont…)........................................................................................................... 11

Technical Specifications (Cont…)........................................................................................................... 12

Appendix B: Power Cabling Guide ............................................................................................................. 13

Appendix C: Manufacturer’s Warranty........................................................................................................ 14

Appendix D: Document Control and Revision History................................................................................... 15