Progressive Dynamics PD1610 User manual

Consult a licensed electrician or RV technician for installation assistance 814420H

Quick Reference Guide for

PD1600 Series Inverter

© 2022 Progressive Dynamics Enterprises, LLC. All rights reserved.

I. LIMITED WARRANTY: Progressive Dynamics warrants its power inverters to be free from defects in material or workmanship under normal use and service;

and limits the remedies to repair or replacement.

II. DURATION: This warranty shall extend for a period of two years from the original date of purchase, and is valid only within the continental limits of the

United States and Canada.

III. WARRANTY EXCLUSIONS: This warranty does not apply to:

A. Any product which has been repaired or altered in any way by an unauthorized person or service station

B. Damage caused by excessive input voltage, misuse, negligence, or accident; or an external force

C. Any product which has been connected, installed, or adjusted or used other than in accordance with the instructions furnished, or has had the serial number

altered, defaced, or removed

D. Cost of all services performed in removing and reinstalling the power inverter

E. ANY LOST PROFITS, LOST SAVINGS, LOSS OF USE OF ENJOYMENT OR OTHER INCIDENTAL DAMAGES ARISING OUT OF THE USE OF,

OR INABILITY TO USE, THE PRODUCT. THIS INCLUDES DAMAGES TO PROPERTY AND, TO THE EXTENT PERMITTED BY LAW, DAM-

AGES FOR PERSONAL INJURY. THIS WARRANTY IN IN LIEU OF ALL OTHER WARRANTIES, INCLUDING WARRANTIES OF MER-

CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

IV. PROOF OF PURCHASE: A warranty claim must be accompanied by proof of the date of purchase.

V. CLAIM PROCEDURE: Upon discovery of a defect, Progressive Dynamics shall be supplied the following information a the address listed below:

A. Name and address of claimant

B. Name, model, and serial number of the product

C. Application in which product was installed. (Included manufacturer, model, and model year where applicable)

D. Date of purchase

E. Complete description of the claimed defect

Upon determination that a warranty claim exists (a defect in material or workmanship occurring under normal use and service) the inverter shall be shipped postage

prepaid to Progressive Dynamics together with proof of purchase. The product will be repaired or replaced and returned postage prepaid.

Mail Returns to: Progressive Dynamics

507 Industrial Road

Marshall, MI 49068

For Warranty Service service@progressivedyn.com

For Full User’s Manual Please Visit:

https://www.progressivedyn.com/service/installation-guides/

Member

See website www.progressivedyn.com

for more trouble shooting information and return instructions

Record the unit’s model and serial number in case you need provide this information in the future. It is much easier to record this

information now, instead of trying to gather it after the unit has been installed.

Model: Serial Number:

PD1610_ (1000 Watt)

PD1618_ (1800 Watt)

PD1620_ (2000 Watt)

Consult a licensed electrician or RV technician for installation assistance 814420H

The PD1600 series inverter comes with a remote display and a 50 ft long connection cable included. The Remote Display is designed for

use with only PD1600 series inverters. The remote will allow complete monitoring of your inverter. This guide will help you install and use

the inverter and the remote control, to monitor the functions.

Materials List

The inverter unit package includes the following items:

(1) PD1600 series inverter remote inverter remote

(1) Owner’s guide & mounting template

(1) Connection cable - (50 ft long connection cable included

with inverter)

NOTE:

If any of the items are missing, contact Progressive Dynamics for replacement.

Use only a cable provided by PDI. DO NOT use a cable that is not designated

for that specific unit.

Included Items & Connecting the Remote

Figure 1 Inverter Remote (Communication cable not shown. 50 ft long cable included standard)

Connecting the remote to the inverter

Plug the connector plug into the port on the top of the inverter and the back of the remote control using the supplied communication

cable (see Figure 2). Failure to use a communication cable provided by PDI may result in damage to the remote display.

It is recommended that you install the remote into the designated location prior to connecting the cable to the remote and the inverter.

Please refer to the installation portion of this guide for those instructions.

Figure 2 Connecting communication cable

Verifying connection

Once the remote display is securely con-

nected to the inverter and the inverter is

turned on, it will begin displaying readouts

immediately. If your remote control display

does not begin to display information, con-

firm that the communication cable is se-

curely connected into both ports on the in-

verter and the remote control.

NOTICE: EQUIPMENT DAMAGE

This Quick Reference Guide is in addition to, and incorporated by reference, the relevant product information for each product in the

PD1600 series inverter. Before reviewing this guide, you must read the relevant product manual. Unless specified, information on safety,

specifications, installation, and operation is as shown in the primary documentation. Ensure you are familiar with that information before

proceeding.

PD1600 series remote displays are compatible ONLY with PD1600 series inverters. Attempting to use a remote display not designated for

that specific inverter could cause damage to the unit and the remote display.

Failure to follow these instructions will result in your inverter to not function properly.

PD1600 Series

Remote Display

(NOTE: REMOTE ACTUALLY

SMALLER THAN INVERTER UNIT)

(NOTE: REMOTE ACTUALLY

SMALLER THAN INVERTER UNIT)

Consult a licensed electrician or RV technician for installation assistance 814420H

WARNING: FIRE HAZARD

DC Input wiring must be protected with properly sized circuit protec-

tion (fuses or circuit breakers).

Never operate the inverter without properly connecting the equipment

ground.

Tighten the nuts on terminals properly. Loose connections cause exces-

sive voltage drop and may cause overheated wires and melted insula-

tion. DO NOT under tighten the screw on the terminal lugs. This will

cause the wires to lose connection.

Failure to follow these instructions may result in serious injury or

death. Failure to follow these instructions may also damage the

unit and/or equipment.

Mounting Instructions

WARNING: FIRE, SHOCK, AND ENERGY HAZARD

Inverter should only be installed by an electrician or a certified RV

technician.

Inverter is NOT ignition protected. Do not mount in the LP gas or bat-

tery compartments.

Inverter should be mounted in a dry, well ventilated space with ade-

quate air flow.

Failure to follow these instructions may result in serious injury or

death. Failure to follow these instructions may also damage the unit

and/or equipment.

Mounting Instructions

Inverter may be installed horizontally or vertically. Vertical

installations should be sure to protect the inverter from for-

eign debris falling inside the unit through the fan openings.

External strain relief should be used for DC input wires.

Inverter can be secured to a flat surface using the side

mounting slots. See Figure 3 and Figure 4 for mounting hole

pattern.

Inverter should be located in a well ventilated compartment.

Minimum compartment dimensions provide 2” of space

above the inverter display and open on the electrical connec-

tion side. Operation in high ambient temperatures require

additional ventilation space.

NOTICE: EQUIPMENT DAMAGE

Do not connect any AC source (such as generator or utility power) to

the AC output wiring of the inverter. Connecting an AC source to the

AC Output of the inverter will result in hazardous conditions.

DO NOT disassemble the inverter. It does not contain any user service-

able parts. Attempting to service the unit yourself could result in an

electrical shock or burn.

Failure to follow these instructions may damage the unit and/or

equipment.

Figure 3:PD1610 Mounting Hole Pattern Figure 4:PD1618/PD1620 Mounting Hole Pattern

Consult a licensed electrician or RV technician for installation assistance 814420H

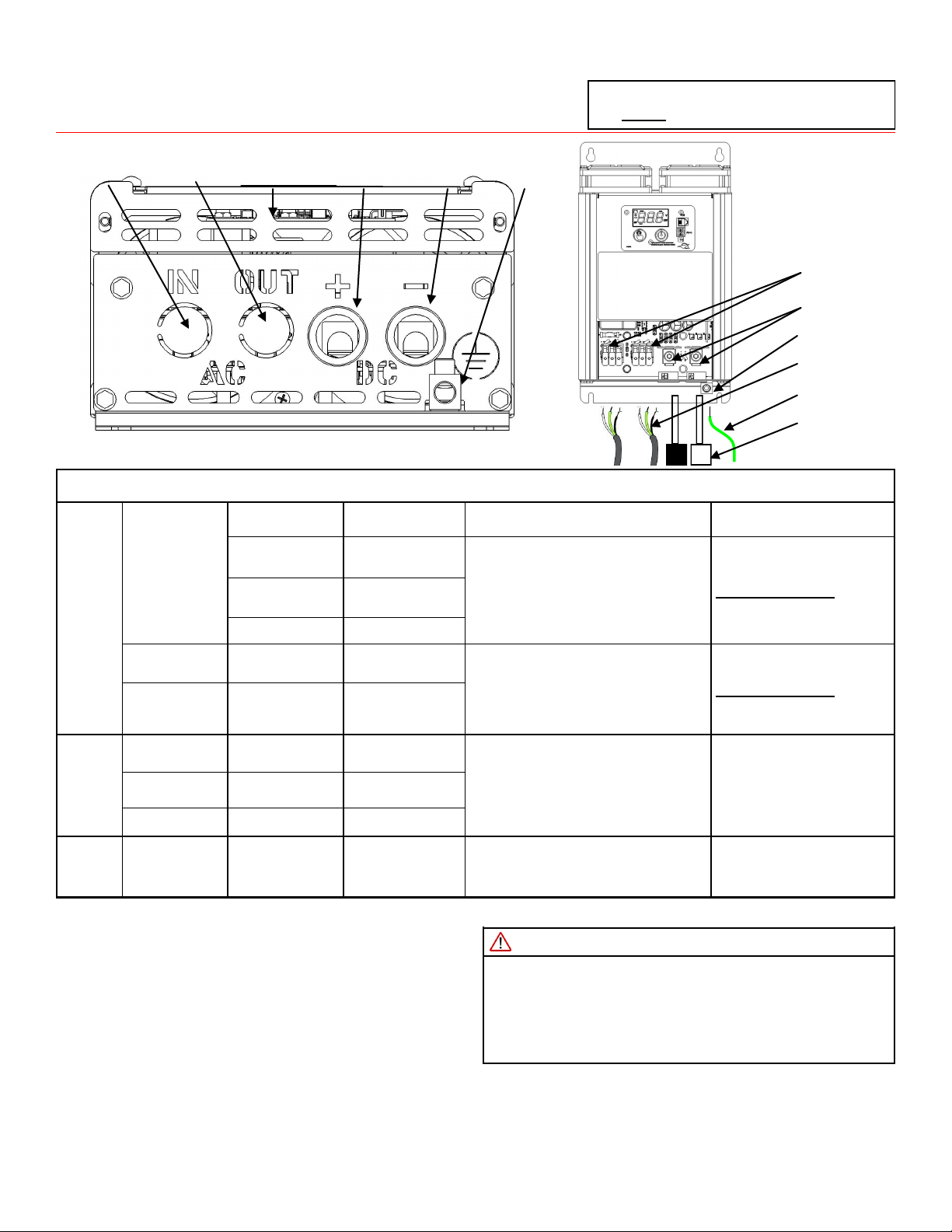

Electrical Connection Instructions

ELECTRICAL CONNECTION INFORMATION

DC

WIRING

PD1610(1kW)

WIRE LENGTH MIN. WIRE SIZE STRIP LENGTH CONNECTION INFO

0-5 ft. #2 AWG

Strip 3/4” (19 mm) insulation from each

cable prior to installation. Do not leave

excess copper exposed.

Tighten lugs to a torque of

100 in-lbs (11.3 N-m).

Do not over tighten.

Fuse: min. 100A for full load

(See NEC for safety codes)

5-10 ft. #1 AWG

10-15 ft. #1/0 AWG

PD1618(1.8kW) 0-10 ft. #2/0 AWG Strip 3/4” (19 mm) insulation from each

cable prior to installation. Do not leave

excess copper exposed.

Tighten lugs to a torque of

200 in-lbs (22.6 N-m).

Do not over tighten.

Fuse: min. 200A for full load

(See NEC for safety codes)

PD1620(2kW) 0-10 ft. #2/0 AWG

PD1610(1kW) 0-100 ft. #14 AWG Solid

Strip 0.6” (15 mm) insulation from each

wire prior to installation. Do not leave

excess copper exposed.

Standard 3/8” trade strain

relief . No torque wrench re-

quired

AC

WIRING PD1618(1.8kW) 0-100 ft. #14 AWG Solid

PD1620(2kW) 0-100 ft. #12 AWG Solid

GND

WIRING PD1600 Series Any #8 AWG

Strip 0.5” (13 mm) insulation from each

wire prior to installation. Do not leave

excess copper exposed.

Torque ground lug to 30-50 in

-lbs.

NOTE: To ensure optimum performance all input wires should be as short as possible. Failure to meet minimum recommended wire size will result in reduced performance

WARNING: FIRE, SHOCK, AND ENERGY HAZARD

Make sure wiring is disconnected from all electrical sources before

handling. All wiring must be done in accordance with local and na-

tional electrical wiring codes.

Failure to follow these instructions may result in serious injury or

death.

Electrical Connection Instructions

1. Ensure all power sources are disconnected from the inverter

2. Remove the wiring cover

3. Remove AC Input knockouts and AC Output knockouts

4. Install 3/8” strain relief in AC Input and AC Output ports

5. Connect AC Out terminal block (Ground, Neutral, and Line)

6. Connect AC In terminal block (Ground, Neutral, and Line)

7. Tighten strain relief (if applicable)

8. Connect DC terminals (positive and negative) to battery with properly sized wires, 5/32” hex (PD1610); 1/4” hex (PD1618/20)

9. When connecting DC wires a small spark may occur. This is normal charging of the inverter’s internal capacitors

10. Provide external strain relief for DC wires

11. Connect equipment ground stud to a grounding point (typically the vehicle’s chassis ) using a 5/32” hex key

12. Re-install the wiring cover

Figure 4

Electrical Connections

Top View

Figure 5 Electrical Connections Side View

PD1600 series inverters are compatible with

BOTH lithium and lead acid batteries.

DC Wiring

Ground Wiring

NOTE:

For PD1600J series, use pre-installed power cord to

connect AC-IN when connecting AC power.

AC Wiring

DC Lugs

Ground Lug

AC Terminal

Blocks

AC Input Wiring

Cover

AC Output Negative DC

Connection

Positive DC

Connection

Equipment

Ground

Consult a licensed electrician or RV technician for installation assistance 814420H

Inverter Display Panel

Figure 6 Inverter on-board Display Panel

Display Features

Power Button: Press to turn on; hold to turn off

Select Button: Cycles between display states:

Input Voltage, Output Voltage, Output

Power, Standby, Error Code (if applicable)

Power Indicator: Lights up green when the inverter is on

Shore Indicator: Lights up yellow when AC input is detected

Low Bat Warning Indicator: Lights up red when the battery

is nearing the end of its charge

PDI Remote Port for externally mounted display

RV-C Port for communication with a RV-C compatible hub

Select

Button Display

Power

Button

PDI Remote Port

(use with PD1601)

RV-C Port

(use with RV-C

Compatible Device)

Figure 7 Inverter Remote Display

Figure 8 Display Indicator (Inverter on-board and remote control)

Power Indicator Shore Power IndicatorLow Bat Warning Indicator Fault Indicator

ERROR CODES

Error Code Condition Action

E-1 Low battery

voltage detected

Re-charge the battery

Check DC cable size

Tighten DC connections

E-2 High battery

voltage shutdown

Disconnect external sources (alternator

or charger)

E-3 AC output

overload

shutdown

Evaluate the loads connected to the AC

outlet of the unit. Loads may need to be

reduced.

E-4 Over-temperature

shutdown

Reduce load to the AC output

Ensure that the inverter is in a dry, well

ventilated space with adequate air flow

Ambient temperature may be too high

E-5 Internal Error Ensure all connections are tightened

Contact the PDI Service Department

E-6 Short Circuit

Look for damaged AC loads

Look for faulty AC wiring

Evaluate peak power requirements for

all loads

E-7 DC Voltage

Failure

Ensure DC connections are tightened

Ensure battery has sufficient capacity

Review minimum wire length and size

requirements

Consult a licensed electrician or RV technician for installation assistance 814420H

Inverter Specifications

*All ratings at 25 °C unless otherwise listed

SPECIFICATIONS

PHYSICAL SPECIFICATIONS TRANSFER SWITCH

PD1610 PD1618 PD1620 PD1610 PD1618 PD1620

Dimensions

L:11.2”(284mm)

W:6.7”(170mm)

H:4.0”(101mm)

L:15.0”(381mm)

W:7.9”(200mm)

H:4.0”(101mm)

L:15.0”(381mm)

W:7.9”(200mm)

H:4.0” (101mm)

Transfer Voltage 95 - 135 VAC

Transfer Time < 50 msec

Net Weight 7 lbs (3.2 kg) 11 lbs (5.0 kg) 11 lbs (5.0 kg) Pass Through

Ampacity 20 AAC 30 AAC

AC OUTPUT DC INPUT

PD1610 PD1618 PD1620 PD1610 PD1618 PD1620

Waveform Pure Sine Wave Nominal Voltage 12.0 VDC

Output

Voltage 120 VAC Under-Voltage

Shutdown 10.5 VDC

Max Power

(Cont) 1000W 1800W 2000W Under-Voltage

Restart 12.0 VDC

Max Power

(Peak) 2000W 3600W 4000W Over-Voltage

Shutdown 15.5 VDC

Frequency 60 Hz Over-Voltage

Restart 15.0 VDC

Peak

Efficiency 90% Max Current @

max load 100 ADC 180 ADC 200 ADC

Installing the remote display on the wall

1. Place the template on the wall (See Figure 10).

2. Measure and mark the wall for the opening to be cut for re-

mote control.

3. Mark the corners of the recess outline on the wall.

4. Measure and mark the two mounting holes for the two

screws on the wall.

5. Cut along the recess outlines on the wall to make a hole for

the remote control.

6. Pre-drill the mounting holes appropriate for mount screws

(not provided) that will be used.

7. Connect the communication cable to the RJ9 port on the in-

verter and the remote control (see Figure 2).

8. Mount the remote panel unit on the wall.

Note:

Ensure that there are no

Obstructions present, such as:

- Pipes

- Insulation

- Electrical Wiring

Ensure that there is at least 1” (25.4 mm) of space for communication cable.

Figure 9

Mounting Diagram

Recommended GFCI for use with PD1610 Inverter:

Leviton GFTR2 (20A), Eaton SGF20 (20A), Bestten USP-20A-20-PKB (20A), Hongki TST20 (20A),

Zhangjiagang City Barep Technology Co. YGH-094 (20A),

Recommended GFCI for use with PD1618/20 Inverter:

Siemens QF130A (30A)

Consult a licensed electrician or RV technician for installation assistance 814420H

Installation Template

Figure 10 Remote Display Mounting Template

[69.89] 2.75

[57.15] 2.25

MOUNTING

HOLE

MOUNTING

HOLE

[101.64] 4.00

[85.85] 3.38

[73.03] 2.87

(Full Scale)

Consult a licensed electrician or RV technician for installation assistance 814420H

P r o g r e s s i ve D y n a m ic s, I n c .

507 Industrial Rd

Marshall, MI 49068

Visit us on the web for other great products.

www.progressivedyn.com

This manual suits for next models

5

Table of contents

Other Progressive Dynamics Inverter manuals

Progressive Dynamics

Progressive Dynamics PD1600 Series User manual

Progressive Dynamics

Progressive Dynamics PD1210SV Operating instructions

Progressive Dynamics

Progressive Dynamics PD1200 Series User manual

Progressive Dynamics

Progressive Dynamics PD1200 Series Operating instructions

Progressive Dynamics

Progressive Dynamics PD1600 Series Operating instructions

Progressive Dynamics

Progressive Dynamics PD1618 Series Operating instructions